A booster assembly

a booster and assembly technology, applied in the field of booster assemblies, can solve the problems of safety risks for mine personnel, safety risks are also compounded, and achieve the effect of facilitating facilitating the engagement of the booster assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

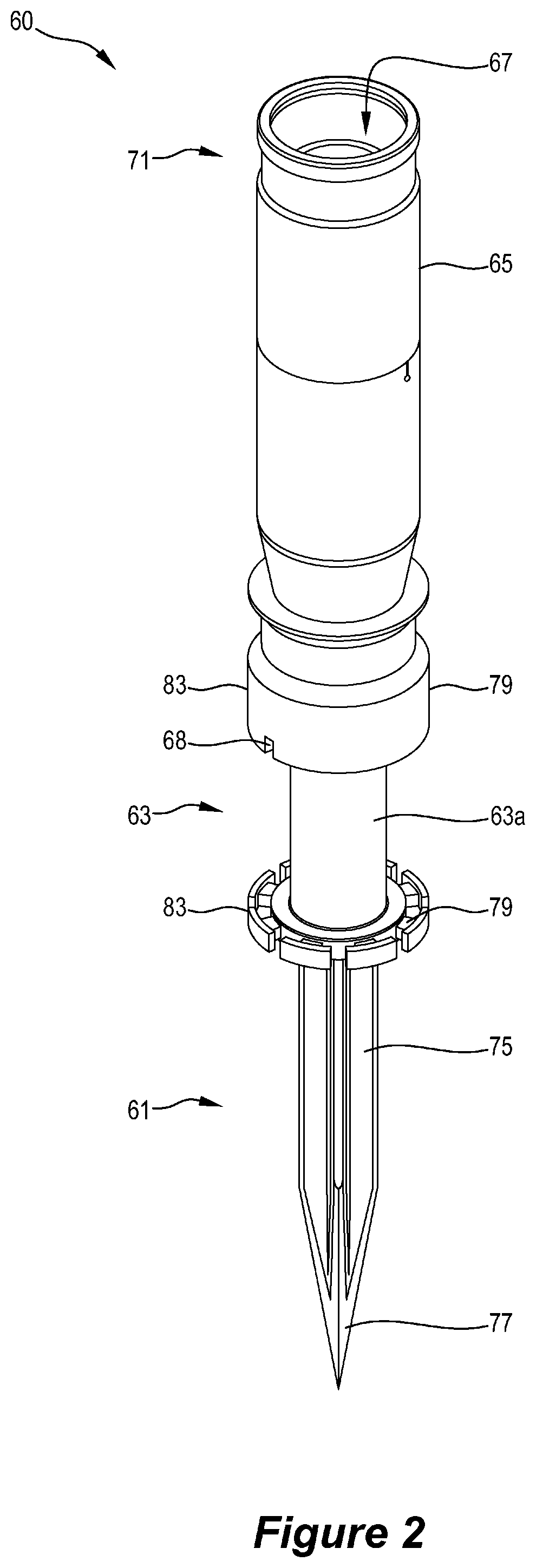

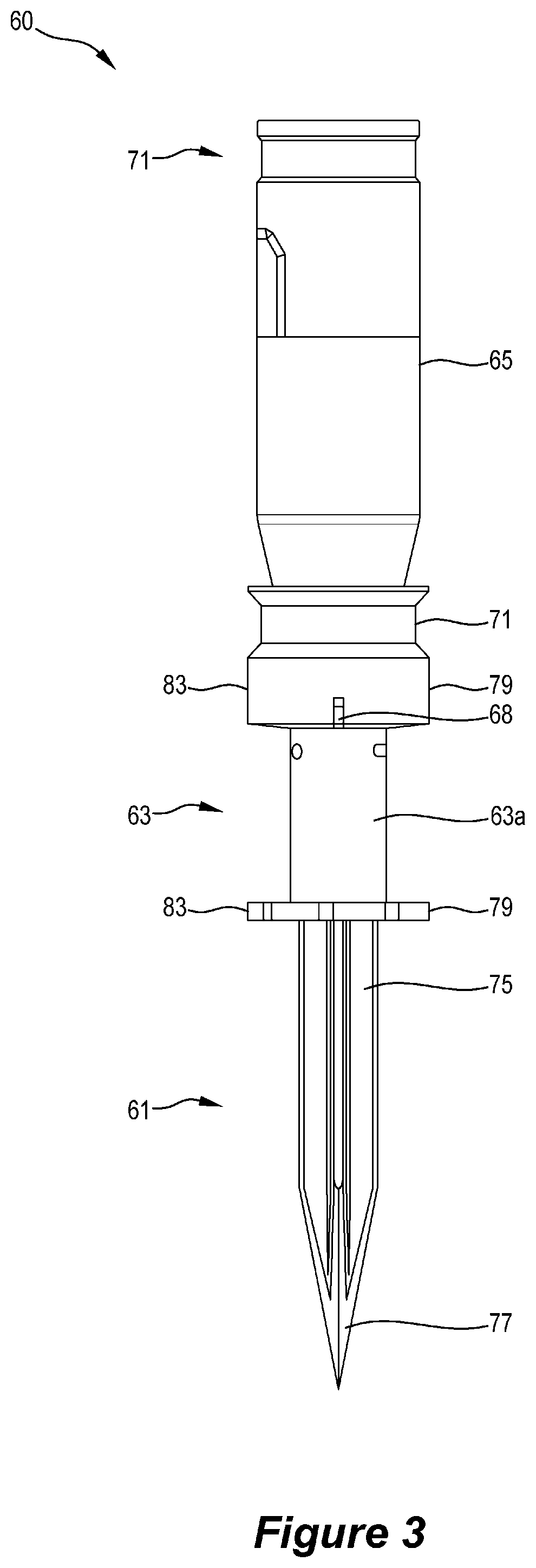

[0079]The embodiments of the booster assembly of the invention are described in the context of use with embodiments of initiation system vehicle (“ISV”) of the invention of the co-pending International application mentioned above.

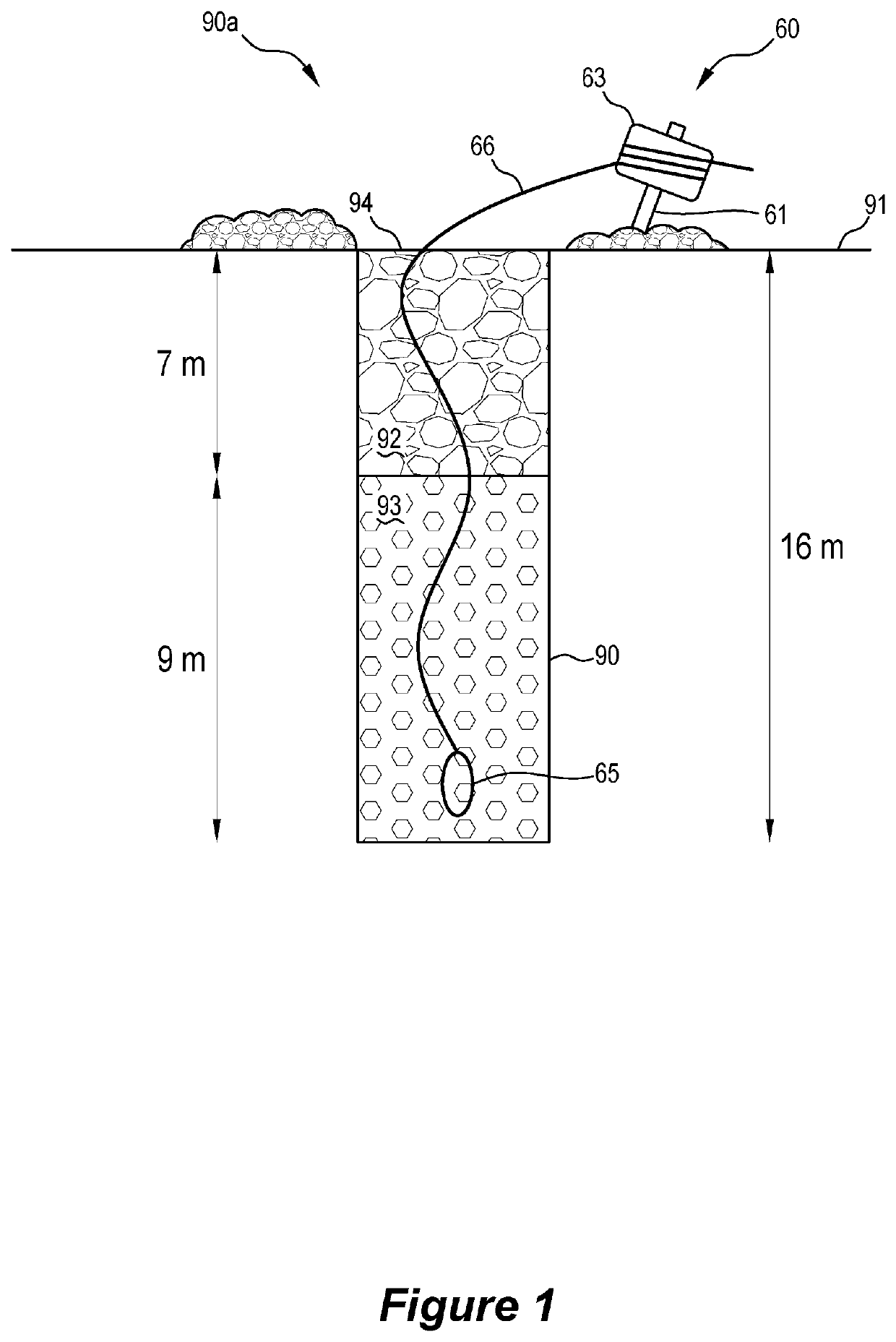

[0080]FIG. 1 illustrates in very schematic form a booster 65 of an embodiment of a booster assembly 60 in accordance with the invention, such as shown in FIGS. 2 to 6, and the other Figures after the initiation system vehicle (“ISV”)—not shown in the Figures but described in more detail below—has positioned the booster 65 in a drilled hole 90 in a pit floor 91 at a selected operative depth submerged in an emulsion explosive 93 in the hole 90, with the hole 90 being stemmed and a detonator cord 66 extending from the stemmed hole 90a.

[0081]As shown in FIG. 1, the drilled hole 90 is filled via the opening 94 to a depth of 9 m with an explosive emulsion 93 rated to operate in high temperature pits, such as produced by Dyna Nobel, the booster 65 is submerged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com