Sensor package structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

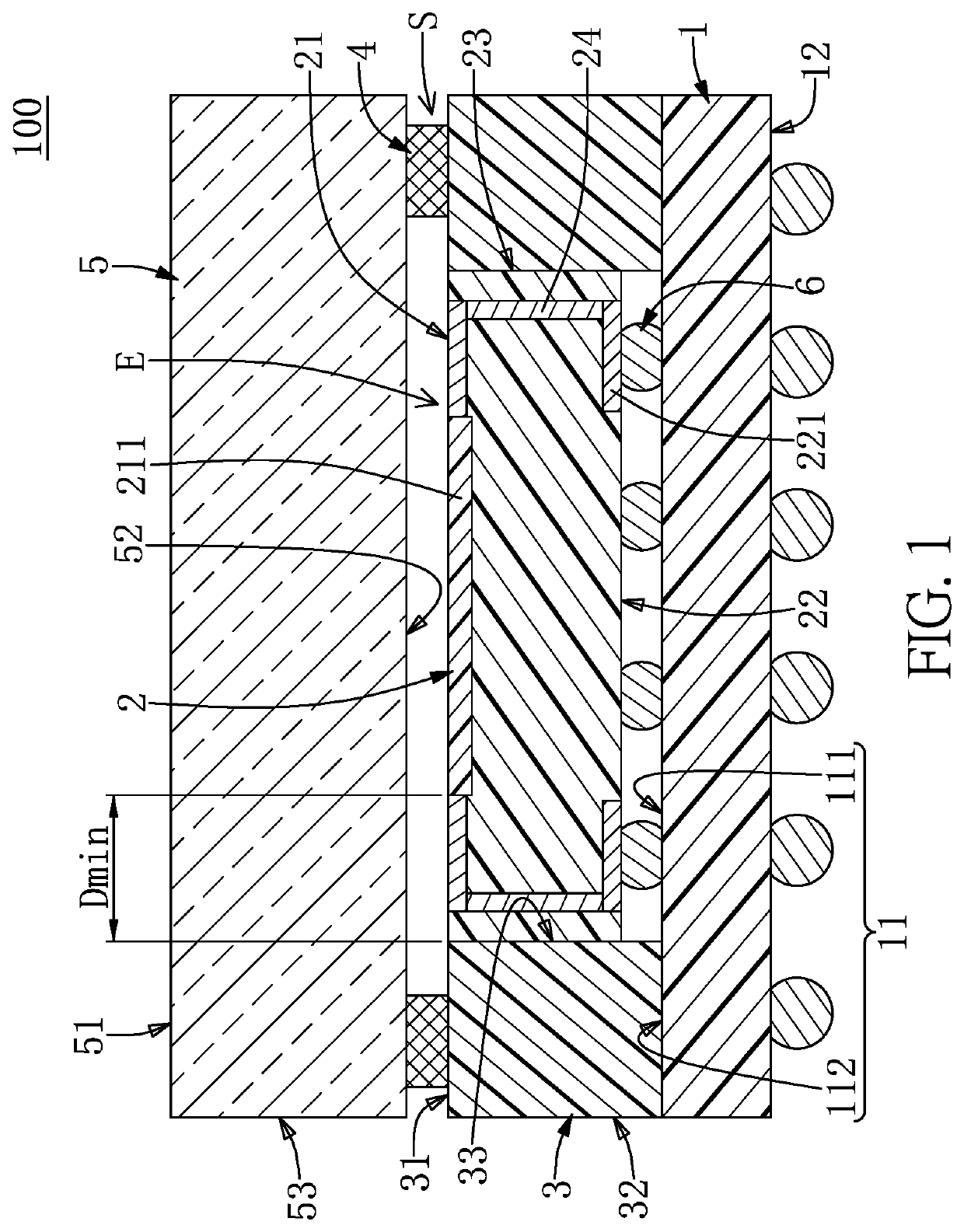

[0019]Referring to FIG. 1, a first embodiment of the present disclosure provides a sensor package structure 100. The sensor package structure 100 includes a substrate 1, a sensor chip 2 disposed on the substrate 1 through a plurality of solder balls 6, a ring-shaped solder mask frame 3 disposed on the substrate 1, a ring-shaped support 4 disposed on the ring-shaped solder mask frame 3, and a light permeable member 5 that is disposed on the ring-shaped support 4. Herein, the sensor package structure 100 in the present embodiment is illustrated as including the above components, but the sensor package structure 100 can be modified according to design requirements.

[0020]It should be noted that in order to conveniently describe the sensor package structure 100 of the present embodiment, FIG. 1 is plotted as a cross-sectional view. It could be understood that some portions of the sensor package structure 100 not shown in FIG. 1 shall have corresponding structures. For example, FIG. 1 sho...

second embodiment

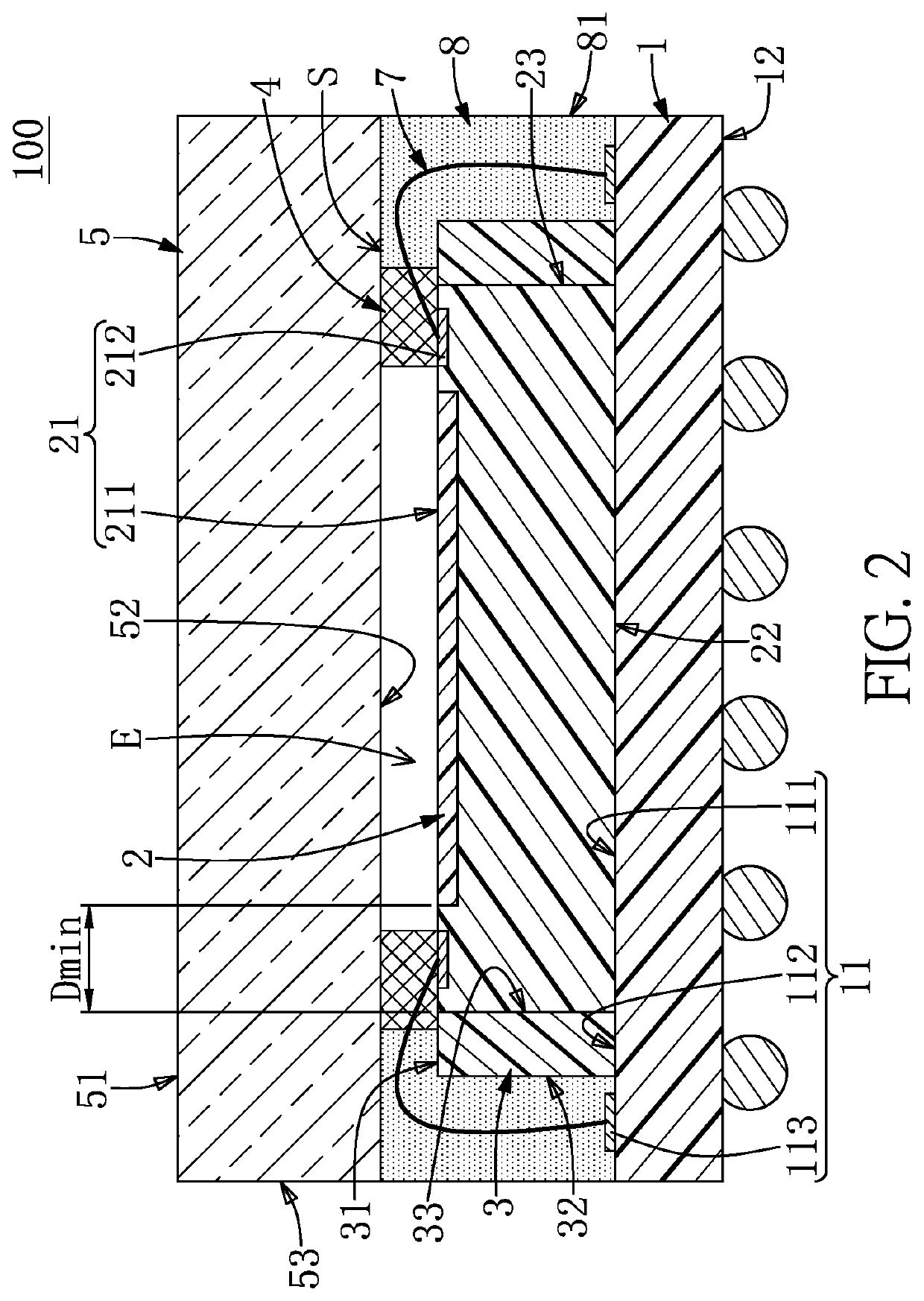

[0029]Referring to FIG. 2, a second embodiment of the present disclosure is disclosed therein. The second embodiment is similar to the first embodiment, so descriptions for identical portions between the two embodiments shall not be repeated again, and the differences between the two embodiments shall be recited in the following.

[0030]In the present embodiment, the sensor package structure 100 includes a substrate 1, a sensor chip 2 disposed on the substrate 1, a ring-shaped solder mask frame 3 disposed on the substrate 1, a ring-shaped support 4 disposed on both the ring-shaped solder mask frame 3 and the sensor chip 2, a light permeable member 5 disposed on the ring-shaped support 4, a plurality of metal wires 7 electrically coupled to the substrate 1 and the sensor chip 2, and a package body 8 that is formed on the substrate 1.

[0031]The substrate 1 includes a plurality of first pads 113 arranged on the first board surface 11. The first pads 113 are located outside of the carrying...

third embodiment

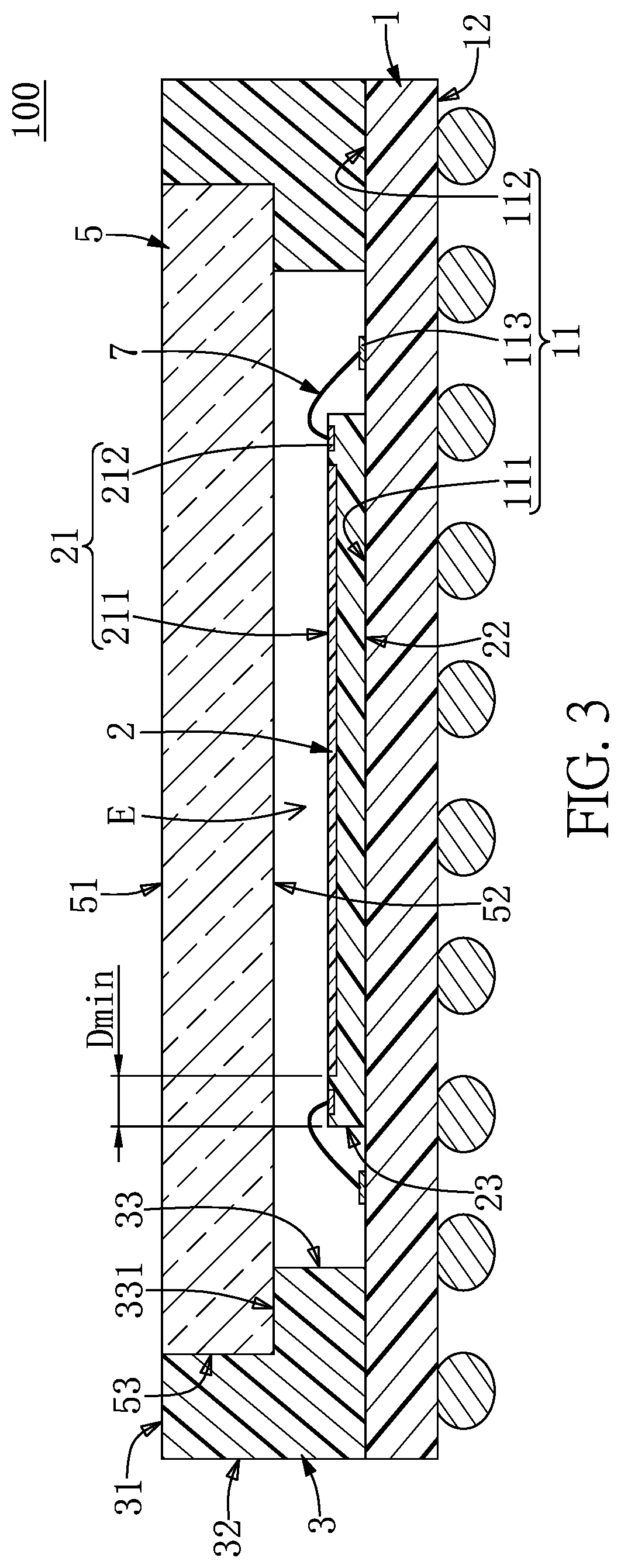

[0035]Referring to FIG. 3 and FIG. 4, a third embodiment of the present disclosure is similar to the first and second embodiments of the present disclosure, so descriptions for identical portions among the embodiments will be not repeated again, and the differences between the first and second embodiments shall be recited in the following.

[0036]In the present embodiment, the ring-shaped solder mask frame 3 is disposed on the carrying region 112 of the first board surface 11 of the substrate 1. The ring-shaped solder mask frame 3 surrounds and is spaced apart from the outer lateral side 23 of the sensor chip 2. In other words, the sensor chip 2 and the metal wires 7 are arranged in a space enclosed by the ring-shaped solder mask frame 3. Moreover, the ring-shaped solder mask frame 3 in the present embodiment is integrally formed as a one-piece structure. The outer lateral side 32 of the ring-shaped solder mask frame 3 is coplanar with the outer lateral side of the substrate 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com