Expansion valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

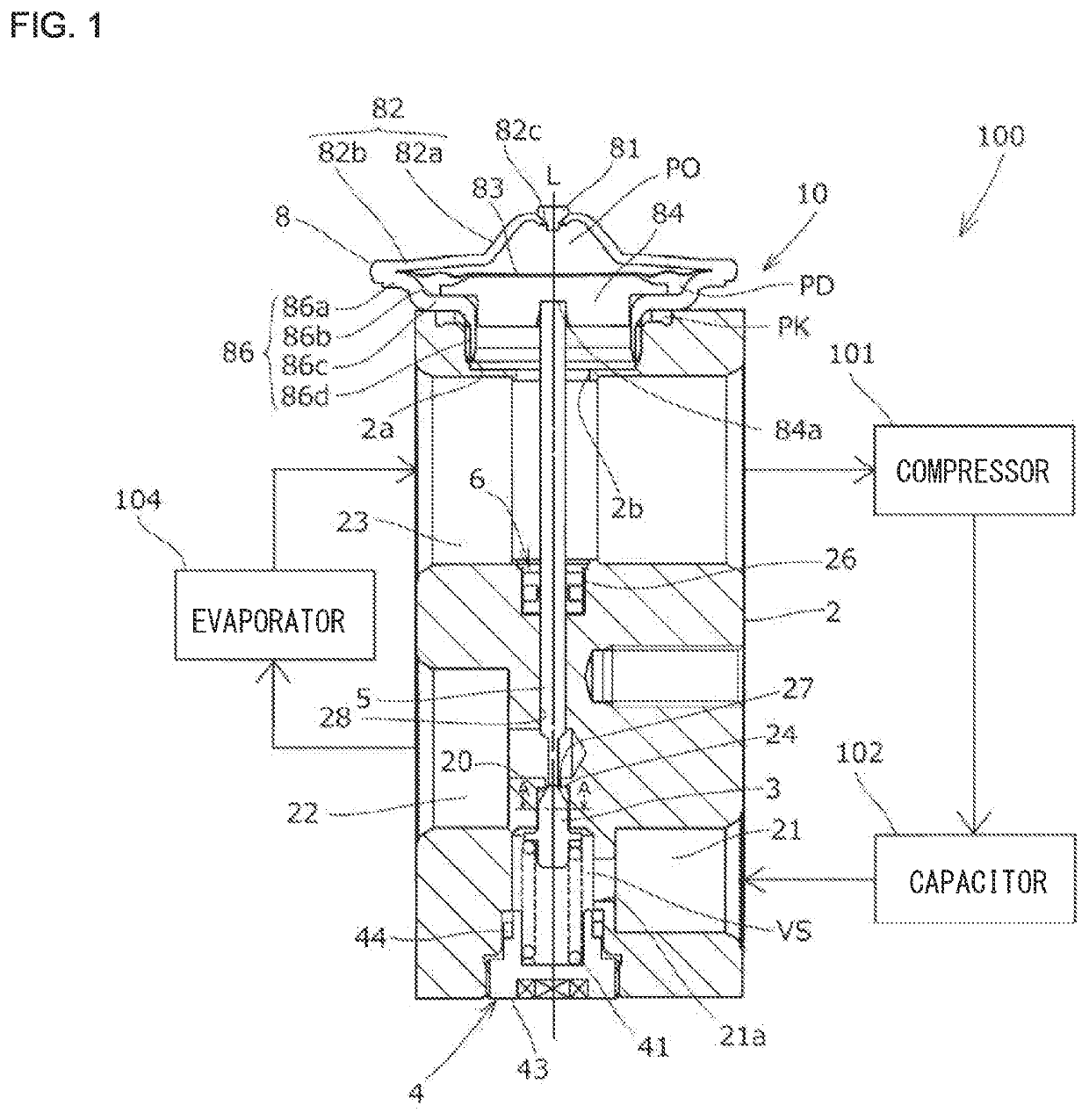

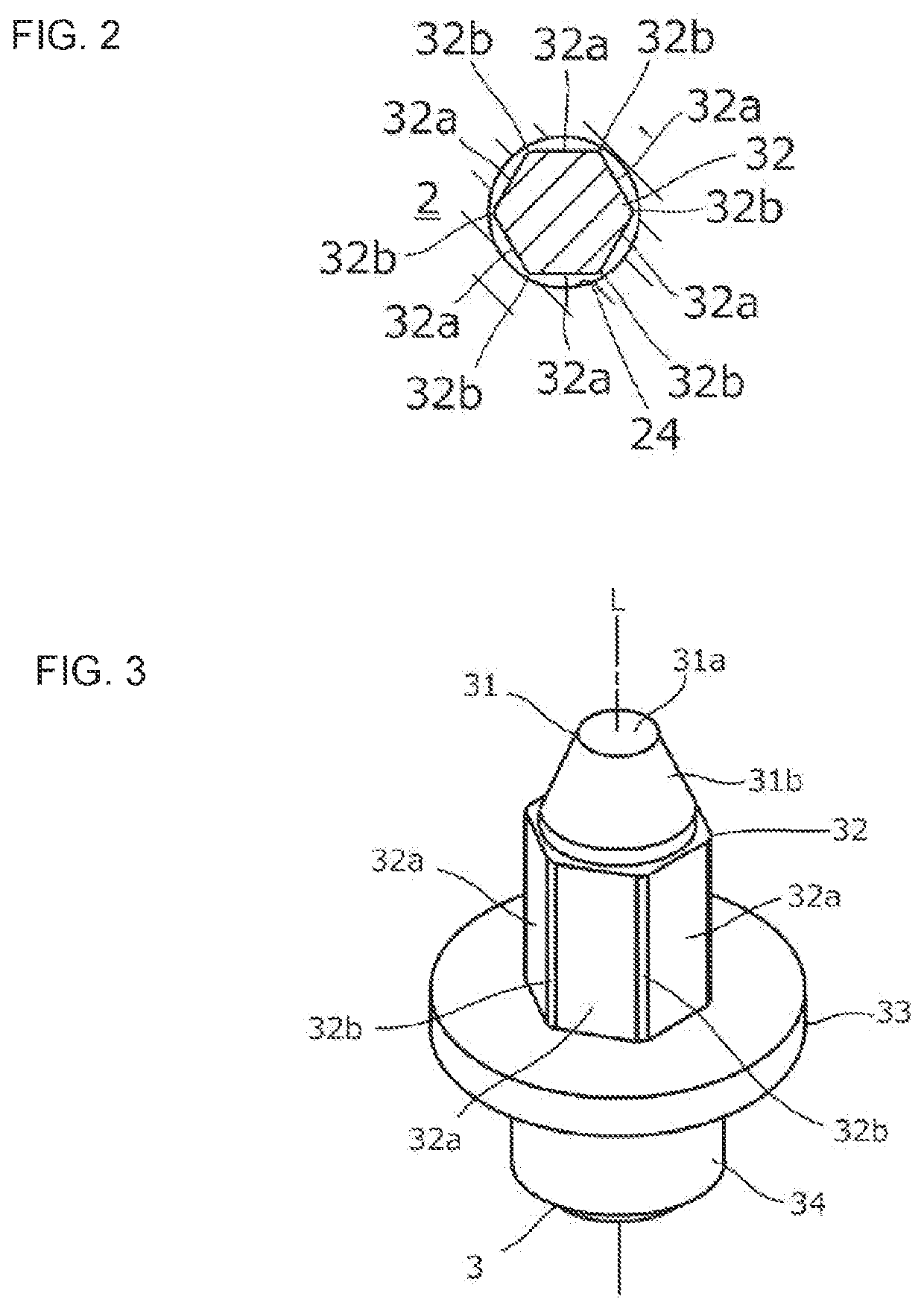

[0030]A general configuration of the expansion valve 10 according to a first embodiment will be described with reference to FIG. 1. FIG. 1 is a schematic cross-sectional view illustrating an example where the expansion valve 10 according to the present embodiment is applied to a refrigerant cycle system 100. In the present embodiment, the expansion valve 10 is connected to a compressor 101, a capacitor 102 and an evaporator 104 that constitute the refrigerant cycle system 100.

[0031]The expansion valve 10 includes a valve main body 2 equipped with a cylindrical valve chamber VS, the valve body 3, an urging device 4, the actuation rod 5, and a ring spring 6.

[0032]The valve main body 2 includes a first flow channel 21 and a second flow channel 22 in addition to a valve chamber VS. The first flow channel 21 is a supply-side flow channel, for example, and a refrigerant, also referred to as a fluid, is supplied to the valve chamber VS via a supply-side flow channel. The second flow channe...

second embodiment

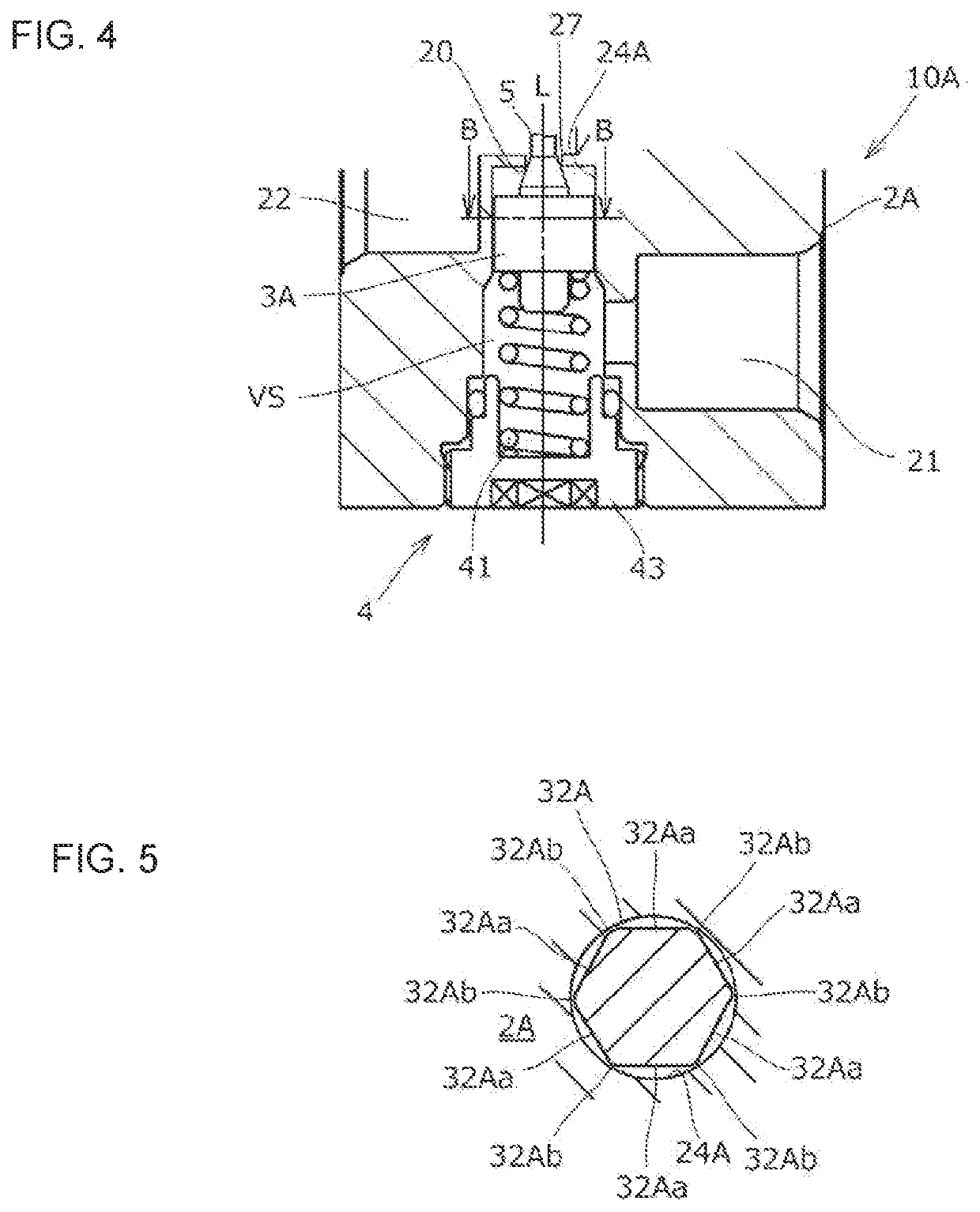

[0061]Next, an expansion valve according to a second embodiment will be described. FIG. 4 is a cross-sectional view illustrating a vicinity of a valve body of an expansion valve 10A in enlarged view. FIG. 5 is a top view of a cross section taken at line B-B of FIG. 4. FIG. 6 is a perspective view of the valve body 3A.

[0062]In FIG. 6, the valve body 3A is formed by consecutively connecting a conical contact portion 31A, a body portion 32A having a hexagonal tubular shape, and an end portion 34A having a cylindrical shape.

[0063]A tapered surface 31Ab of the contact portion 31A is abutted against the valve seat 20. Further, an upper surface 31Aa of the contact portion 31A is a plane surface that is orthogonal to the axis L. An outer circumference of the body portion 32A is composed of six plane surfaces 32Aa and connecting surfaces 32Ab that are formed between adjacent plane surfaces 32a. Each connecting surface 32b can either be a plane surface or a curved surface. The peripheral leng...

third embodiment

[0068]Next, an expansion valve according to a third embodiment will be described. FIG. 7 is a cross-sectional view illustrating a vicinity of a valve body of an expansion valve 10B in enlarged view. FIG. 8 is a top view of the cross section taken at line C-C of FIG. 7. FIG. 9 is a perspective view of a valve body 3B.

[0069]In FIG. 9, the valve body 3B is formed by consecutively connecting a conical contact portion 31B, a body portion 32B having a cylindrical shape, a flange portion 33B having a disk shape, and an end portion 34B having a cylindrical shape.

[0070]A tapered surface 31Bb of the contact portion 31B is abutted against the valve seat 20. Further, an upper surface 31Ba of the contact portion 31B is a plane surface that is orthogonal to the axis L. The length of the body portion 32B should preferably be the same as a maximum diagonal length of an inner wall 24B of the valve chamber VS (or a diameter of the body portion 32B) or greater.

[0071]As illustrated in FIG. 8, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com