Mobile asphalt plant

a technology of mobile asphalt plant and drum, which is applied in the direction of roads, roads, construction, etc., can solve the problems of large amount of heat required, large heat loss, and impeded drum movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

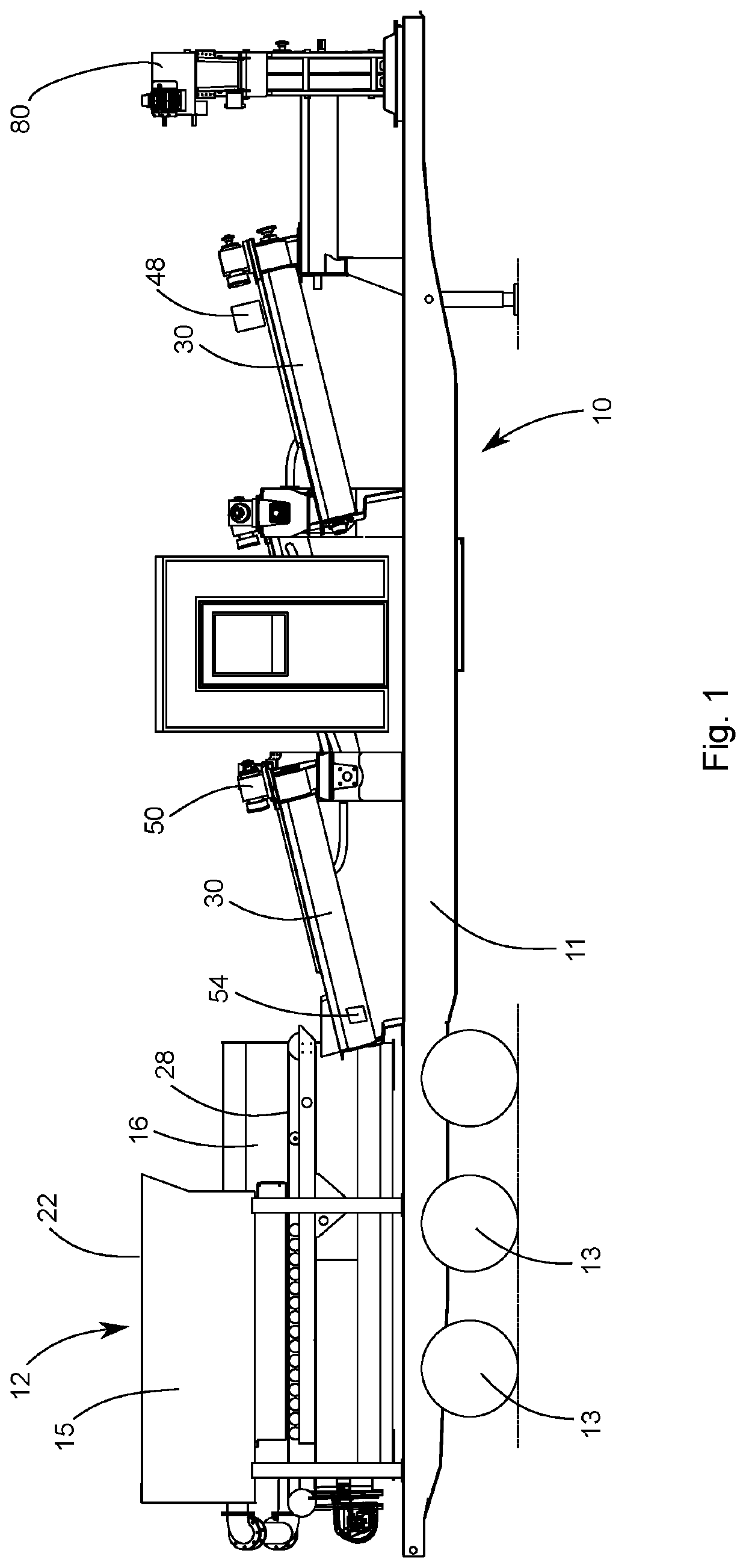

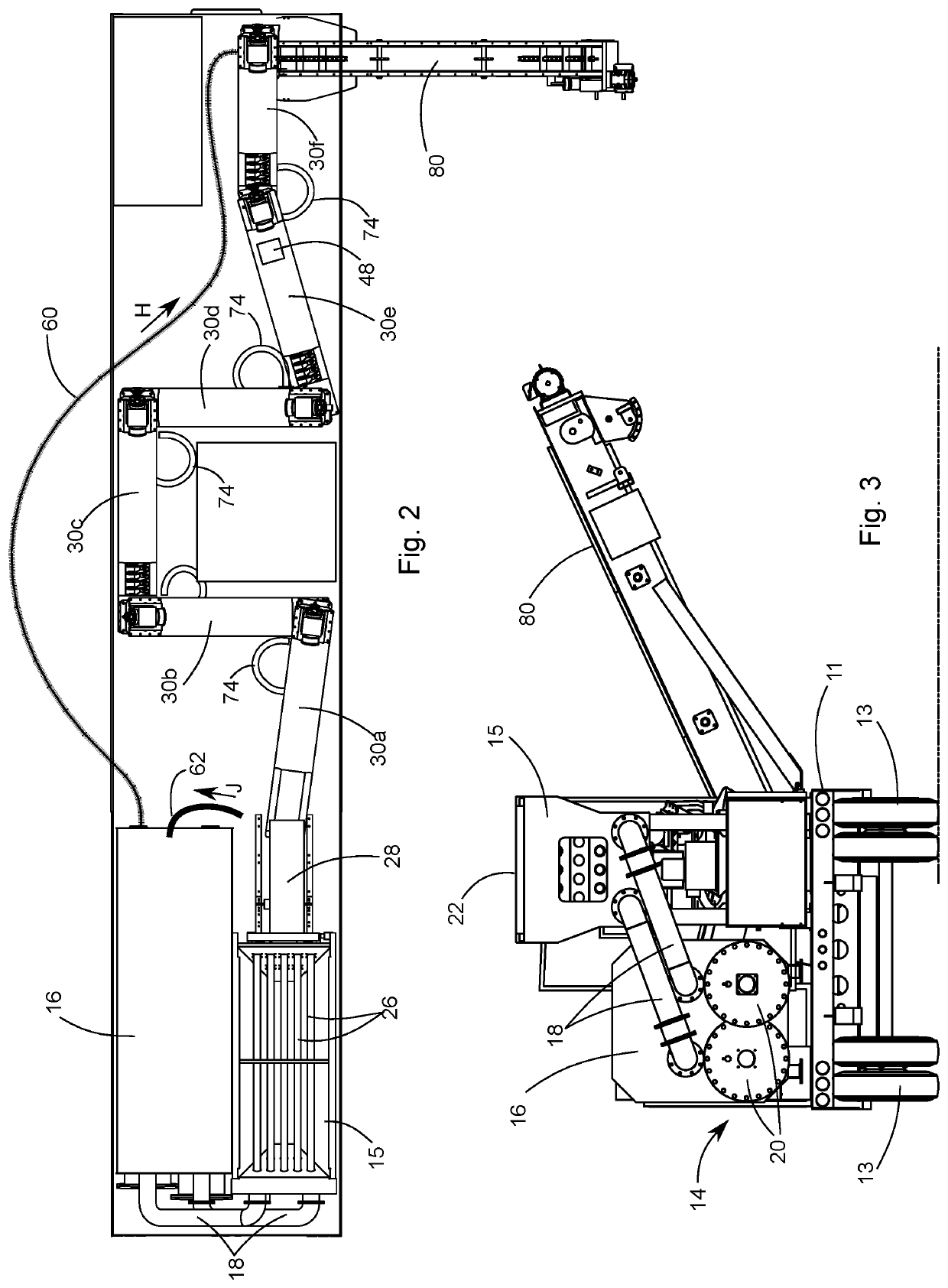

[0053]Referring to FIGS. 1 to 3, a mobile asphalt plant 10 in accordance with the invention may take the form of a trailer, comprising a bed 11 supported by a plurality of wheels 13. The mobile asphalt plant 10 further comprises a container unit 12 configured to receive aggregate material 2 (for example, crushed gravel or other suitable material) to be used in producing asphalt. The mobile asphalt plant 10 also comprises a heating unit 14 for providing heat for the mobile asphalt plant 10. The container unit 12 and the heating unit 14 are preferably supported on the bed 11.

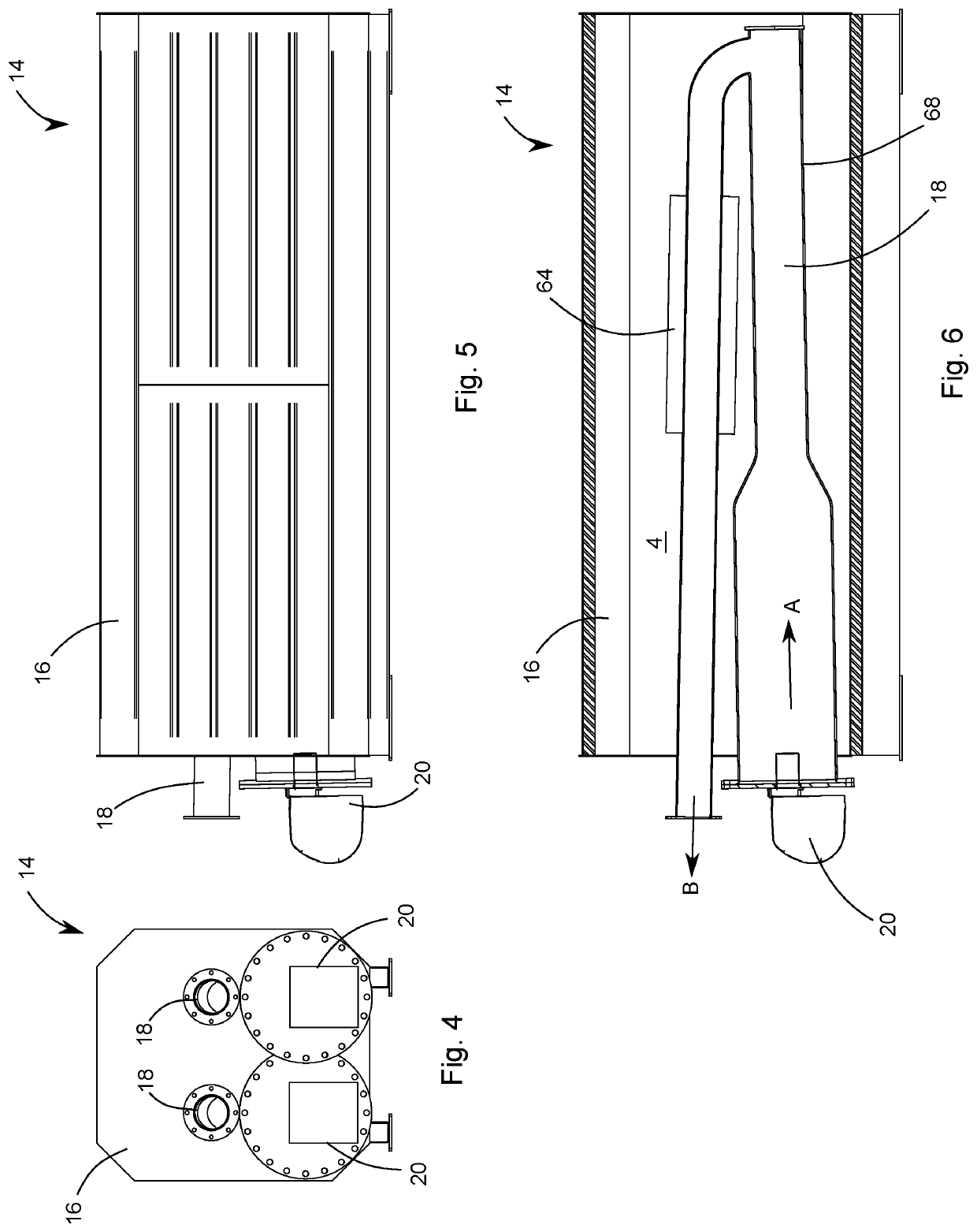

[0054]Referring to FIGS. 4 to 6, in one embodiment, the heating unit 14 comprises a tank 16 and one or more first plenum tubes 18. The tank 16 is configured to hold heat transfer oil 4. The one or more first plenum tubes 18 extend into and within the tank 16. The heating unit 14 further comprises one or more heaters 20 that are connected to the first plenum tubes 18. The heaters 20 are configured to provide heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com