Smoking substitute apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0213]There now follows a disclosure of certain examples of experimental work undertaken to determine the effects of certain conditions in the smoking substitute apparatus on the particle size of the generated aerosol. However, the present disclosure is to be understood to not be limited in its application to the specific experimentation, results, and laboratory procedures disclosed herein after. Rather, the Examples are simply provided as one of various embodiments and are meant to be exemplary, not exhaustive.

Introduction

[0214]Aerosol droplet size is a considered to be an important characteristic for smoking substitution devices. Droplets in the range of 2-5 μm are preferred in order to achieve improved nicotine delivery efficiency and to minimize the hazard of second-hand smoking. However, at the time of writing (September 2019), commercial EVP devices typically deliver aerosols with droplet size averaged around 0.5 μm, and to the knowledge of the inventors not a single commercia...

first example

ube Testing

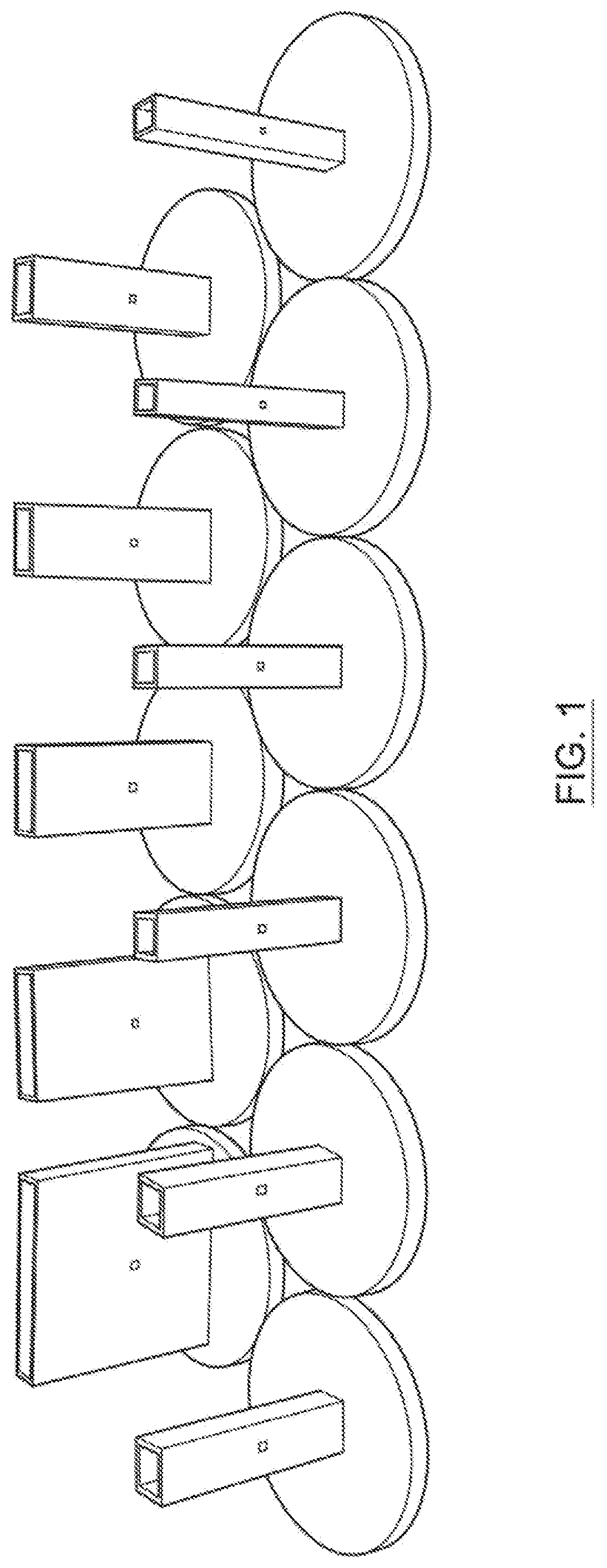

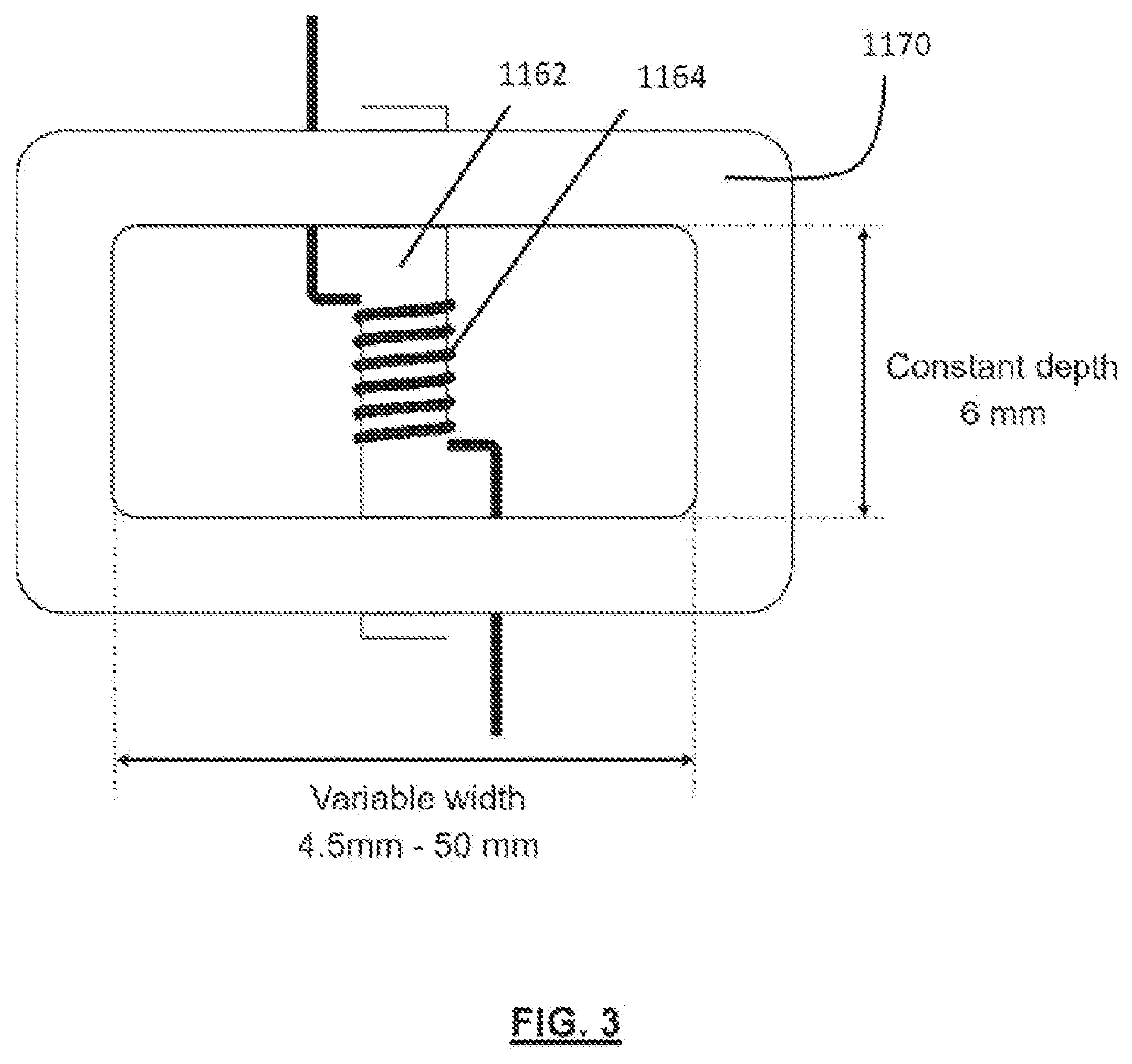

[0220]The work of a first example reported here based on the inventors' insight that aerosol particle size might be related to: 1) air velocity; 2) flow rate; and 3) Reynolds number. In a given EVP device, these three parameters are inter-linked to each other, making it difficult to draw conclusions on the roles of each individual factor. In order to decouple these factors, experiments of a first example were carried out using a set of rectangular tubes having different dimensions. These were manufactured by 3D printing. The rectangular tubes were 3D printed in an MJP 2500 3D printer. FIG. 1 illustrates the set of rectangular tubes. Each tube has the same depth and length but different width. Each tube has an integral end plate in order to provide a seal against air flow outside the tube. Each tube also has holes formed in opposing side walls in order to accommodate a wick.

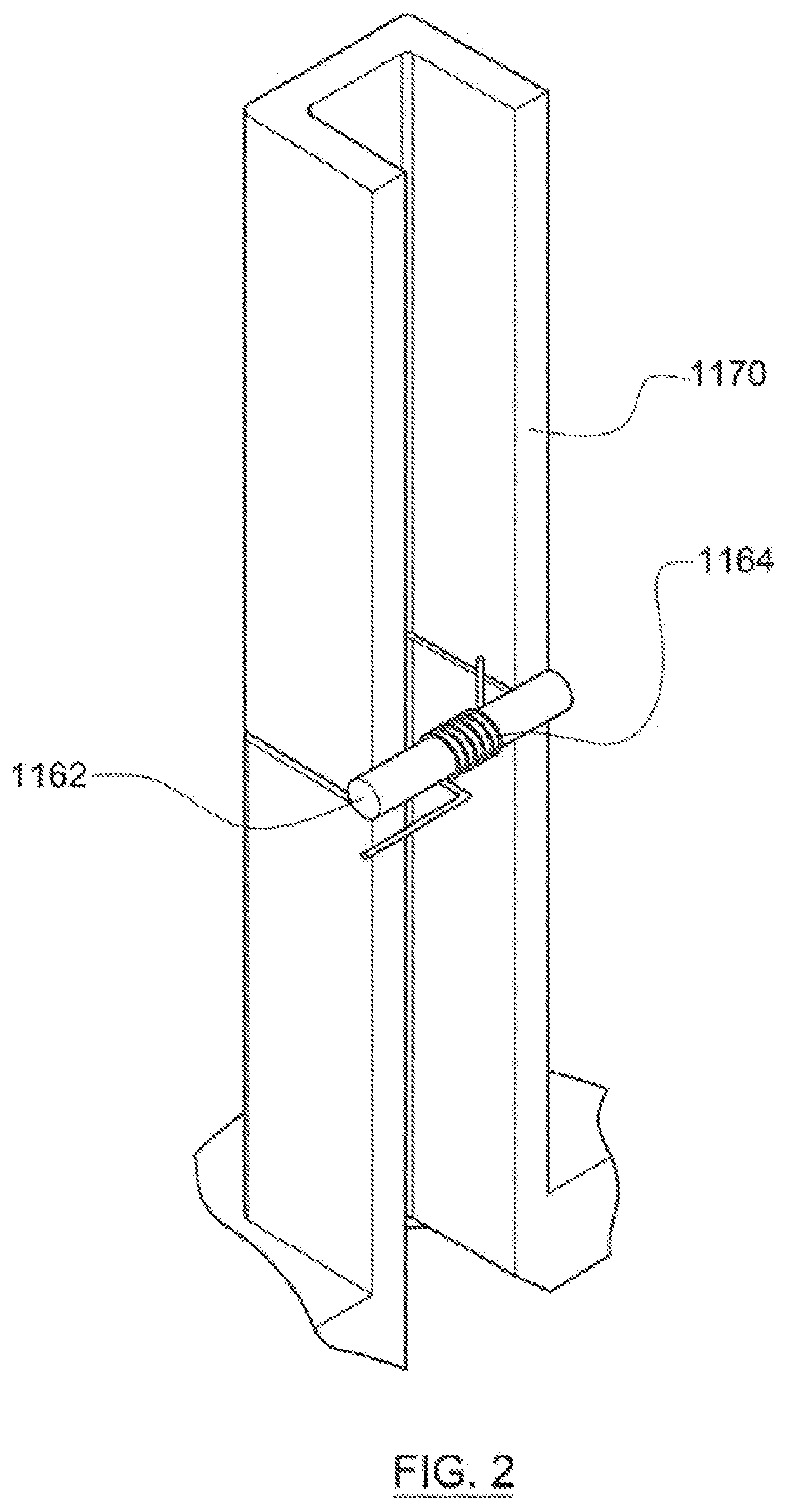

[0221]FIG. 2 shows a schematic perspective longitudinal cross sectional view of an example rectangul...

fourth example

ling

[0247]Air velocity in the vicinity of the wick is believed to play an important role in affecting particle size. In the first example, the air velocity was calculated by dividing the flow rate by the intersection area, which is referred to as “calculated velocity” in a fourth example. This involves a very crude simplification that assumes velocity distribution to be homogeneous across the intersection area.

[0248]In order to increase reliability of the fourth example, computational fluid dynamics (CFD) modelling was performed to obtain more accurate velocity values:[0249]1) The average velocity in the vicinity of the wick (defined as a volume from the wick surface to 1 mm away from the wick surface)[0250]2) The maximum velocity in the vicinity of the wick (defined as a volume from the wick surface to 1 mm away from the wick surface)

TABLE 2Average and maximum velocity in the vicinity of wick surface obtained from CFD modelling.Tube Flow CalculatedAverageMaximumsizeratevelocity*vel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com