Inter-casing pressure control systems and methods

a pressure control system and casing technology, applied in the direction of fluid removal, survey, borehole/well accessories, etc., can solve the problem of gas and fluid release, serious health, safety and environmental (hse) problems in the area, and the possibility of accidental ignition of escaped hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Introduction to Present Technology

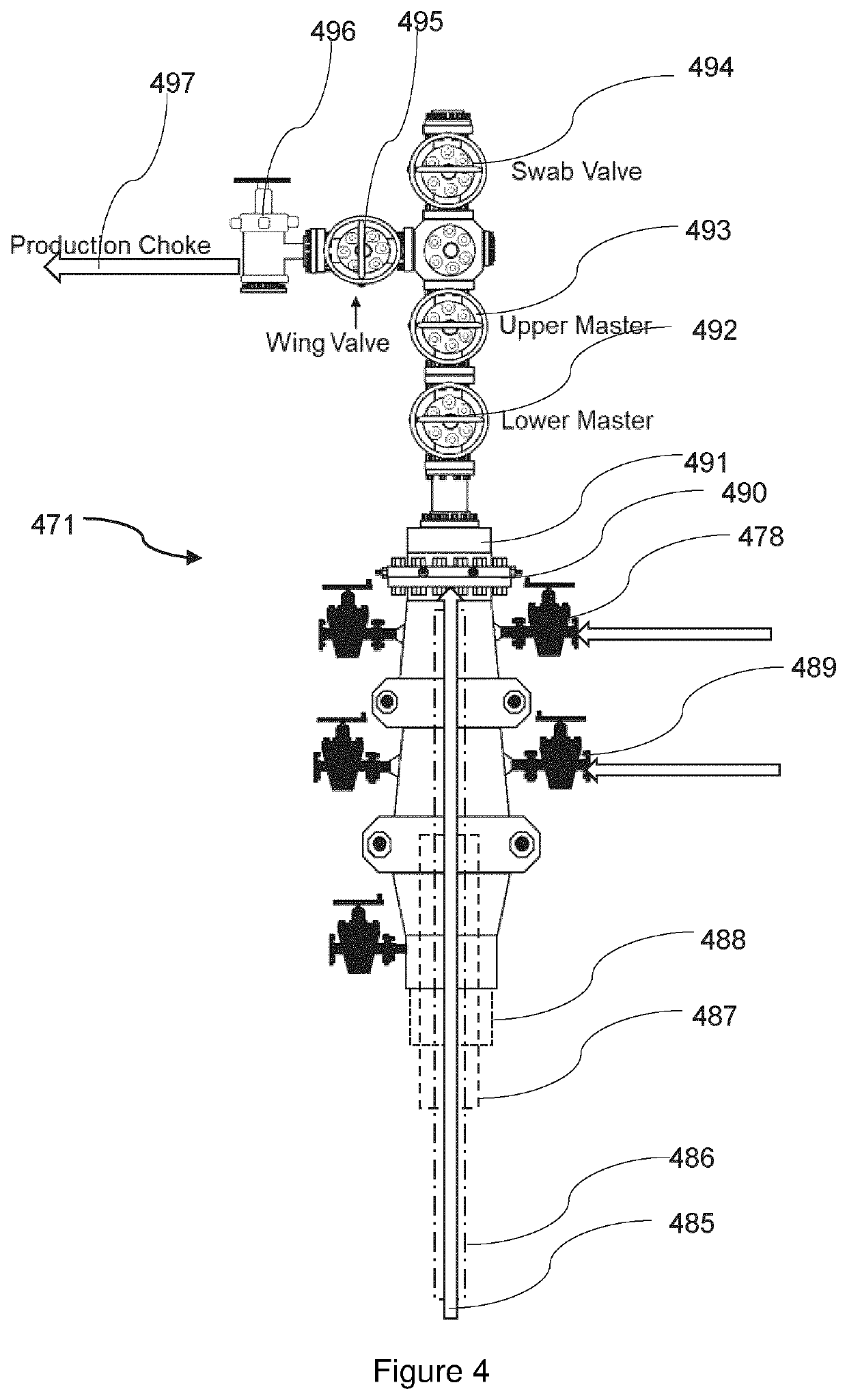

[0112]The present disclosure describes using a dynamic bleed and lube process that will use hydraulic pressure to continuously, gently and automatically inject a high-density cesium formate brine solution into the cement sheath within an inter-casing annulus. The fluid can flow into small fissures in the cement sheath displacing fluids (e.g. liquid and / or gases) as it flows. Once the fissures are filled with brine, further influx of fluids may be prevented. This may help increase the hydrostatic force in the well bore, stop the continued influx of oil and gas into the cement annulus and / or buffer the corrosive nature of H2S and CO2 present in the cement sheath.

[0113]The present process uses a monovalent heavy cesium formate brine to create hydrostatic pressure in the cement annulus which will reduce the influx of fluids into the cement annulus from below and after a period of time reach a balance point which will, over time result in a substantial r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com