Catadioptric lens system for collecting and directing light from large aperture luminescent light illuminating fixtures

a technology of dioptric lens and luminescent light, which is applied in the field of luminescent illumination systems, can solve the problems of unacceptably large aperture and frustrating efforts to direct and shape the emitted ligh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

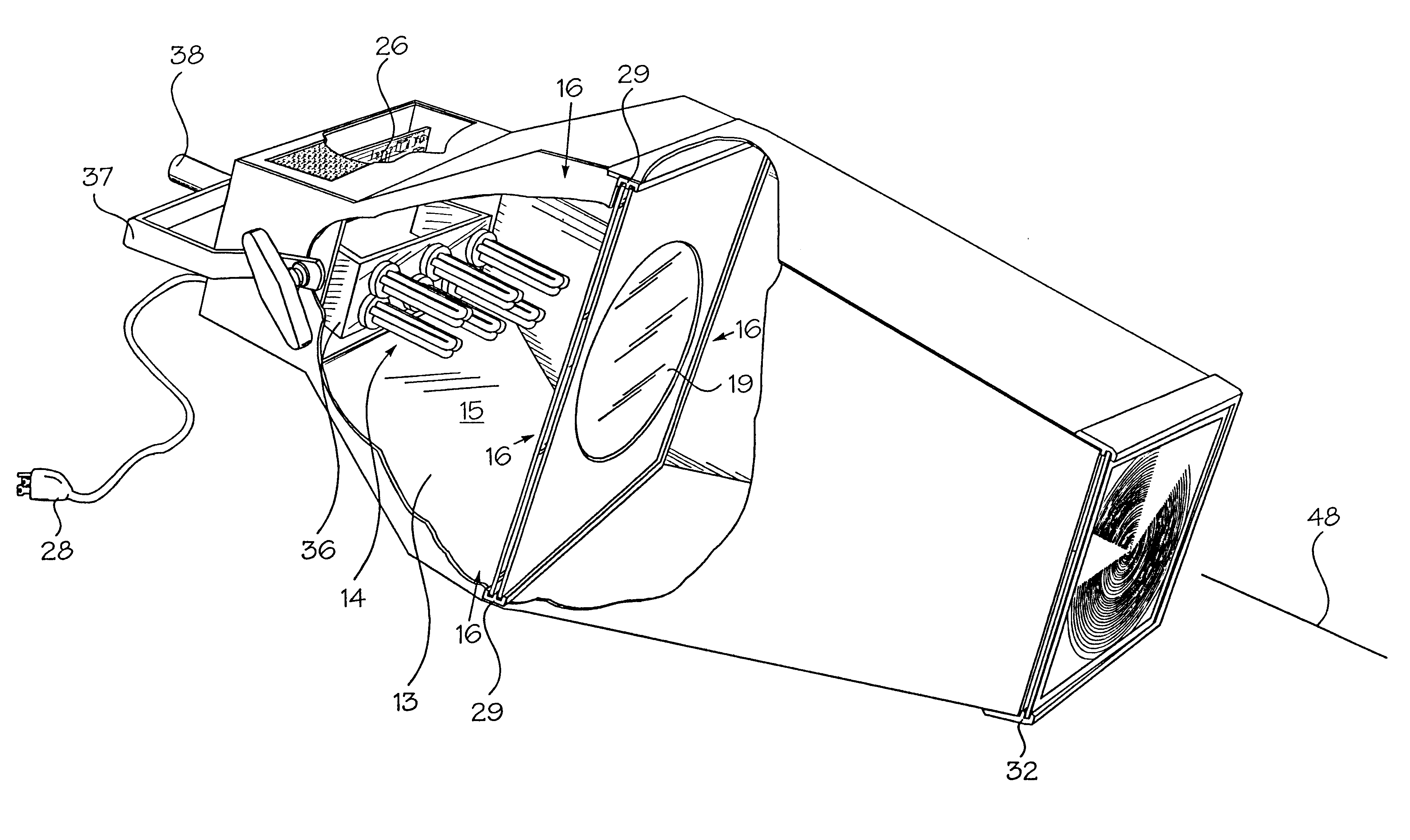

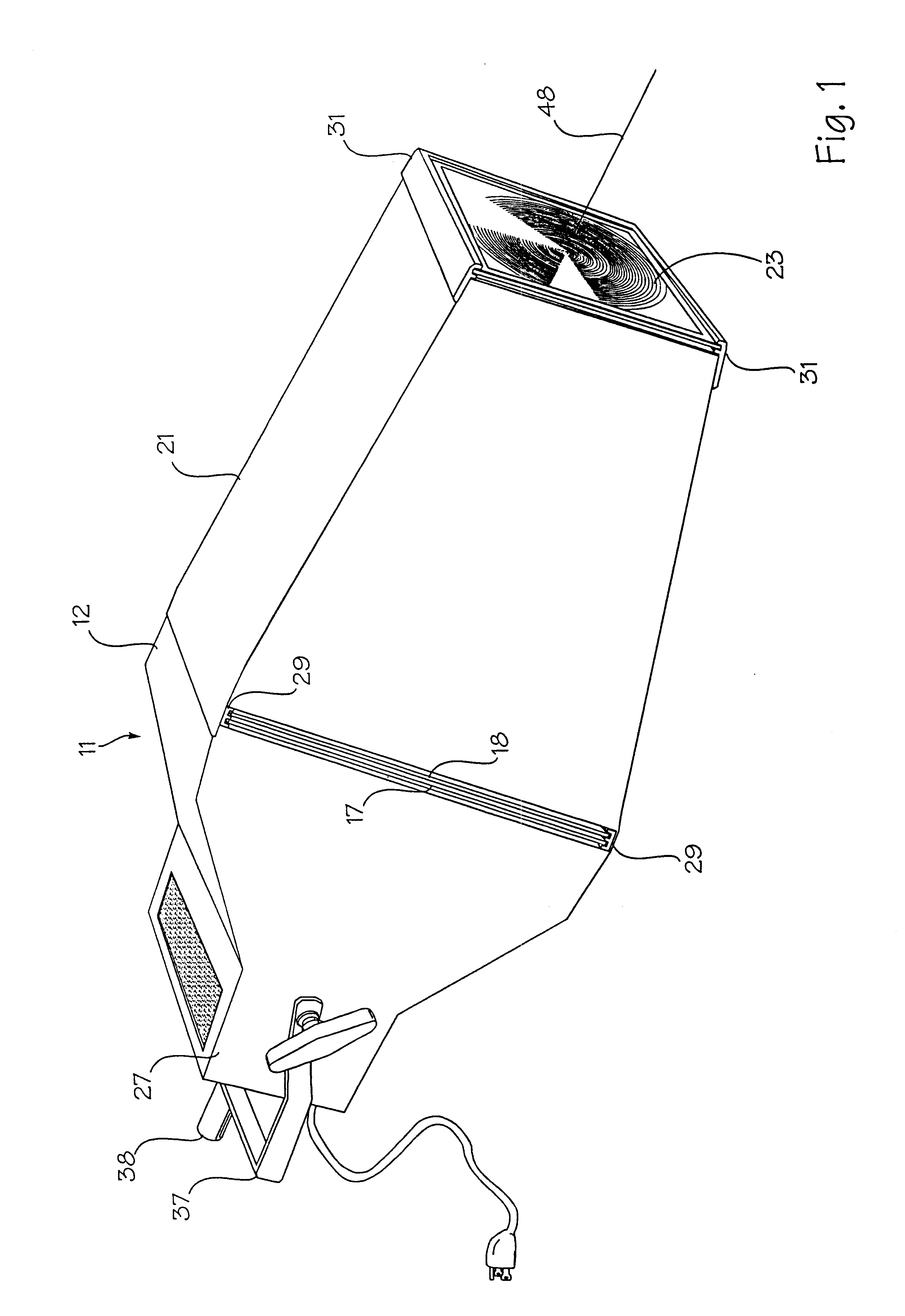

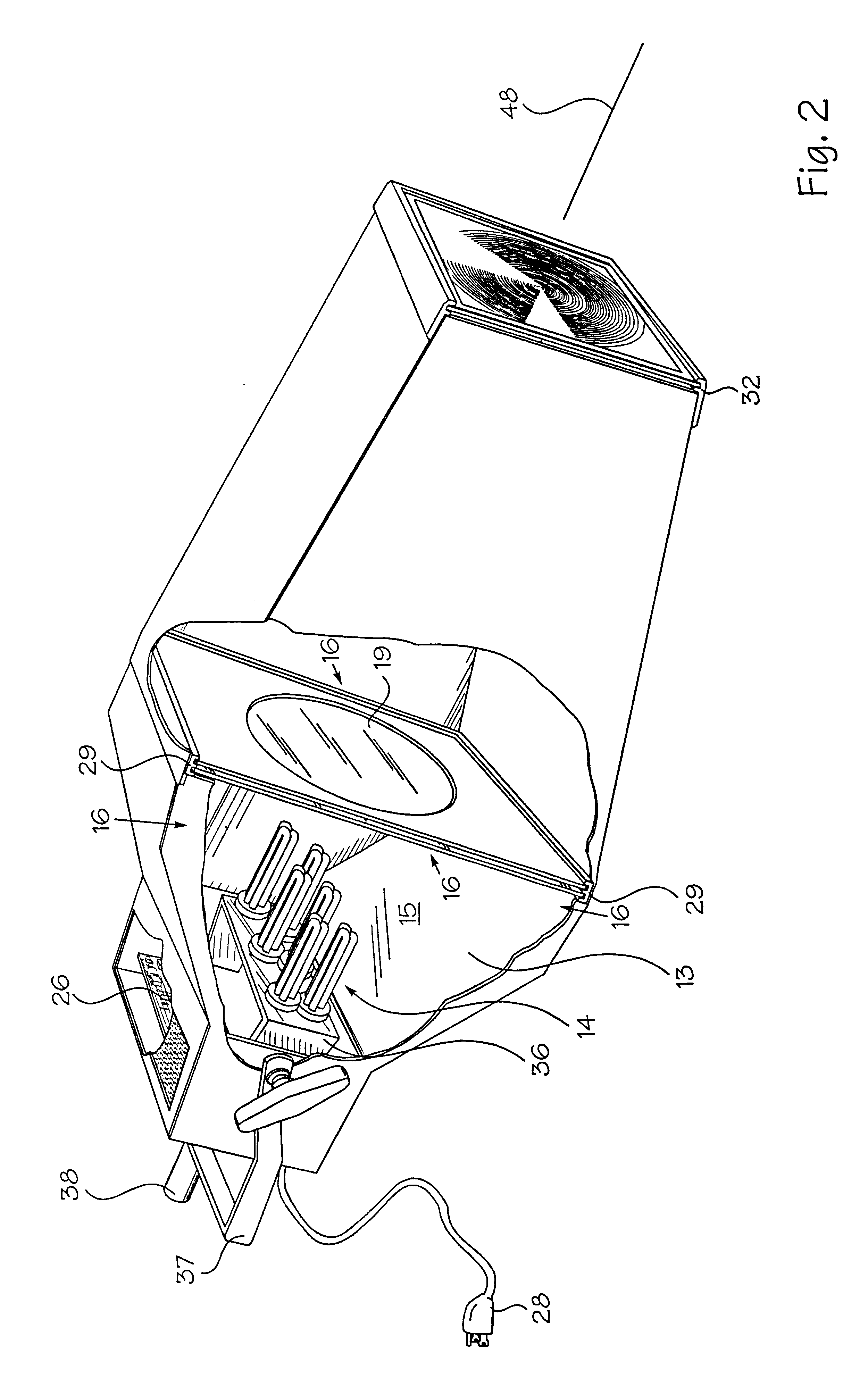

Looking at FIGS. 1 through 4, the invented projection illumination fixture 11 includes a reflector housing 12 with internally supported reflecting surfaces 13 defining a trapezoidal hexahedron light cavity volume 15 directing light emitted by a plurality of trichromatic luminescent light tubes 14 toward a reflector cavity aperture 16 at its base. A transmissive catadioptric lens 17 is disposed across the reflector cavity aperture 16 for optically collecting the light dispersively radiating toward the cavity aperture and converting it into a more-or-less or directed "divergent" light beam. A gobo 18 with a pre-selected shaped aperture 19 is located immediately outward from the catadioptric lens 17 for shaping the cross section configuration of the directed light beam from the catadioptric lens 17. A light snoot or barrel 21 secured to the reflector housing 12 tapers to a second rectangular snoot aperture 22 slightly smaller than the reflector cavity aperture 16. A projection lens 23,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com