Under-bed fifth wheel mounting system

a fifth wheel and mounting system technology, applied in the direction of loading/unloading vehicle arrangment, transportation items, load accommodation, etc., can solve the problems of high undesirable permanent mounting system, typical not used on a regular basis, and unsightly mounting system, etc., to achieve convenient removal of hitches, strong, rigid connection points, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

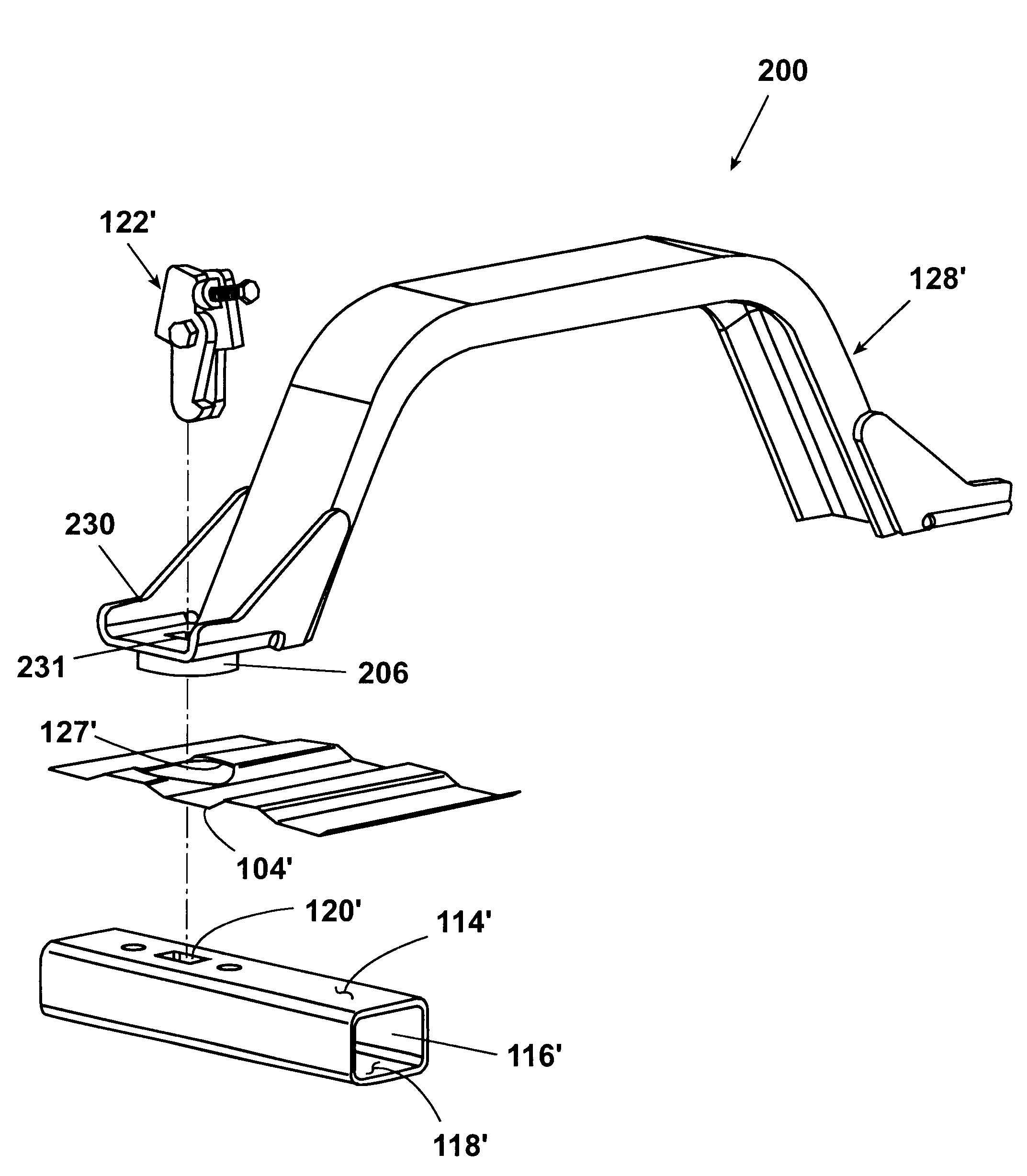

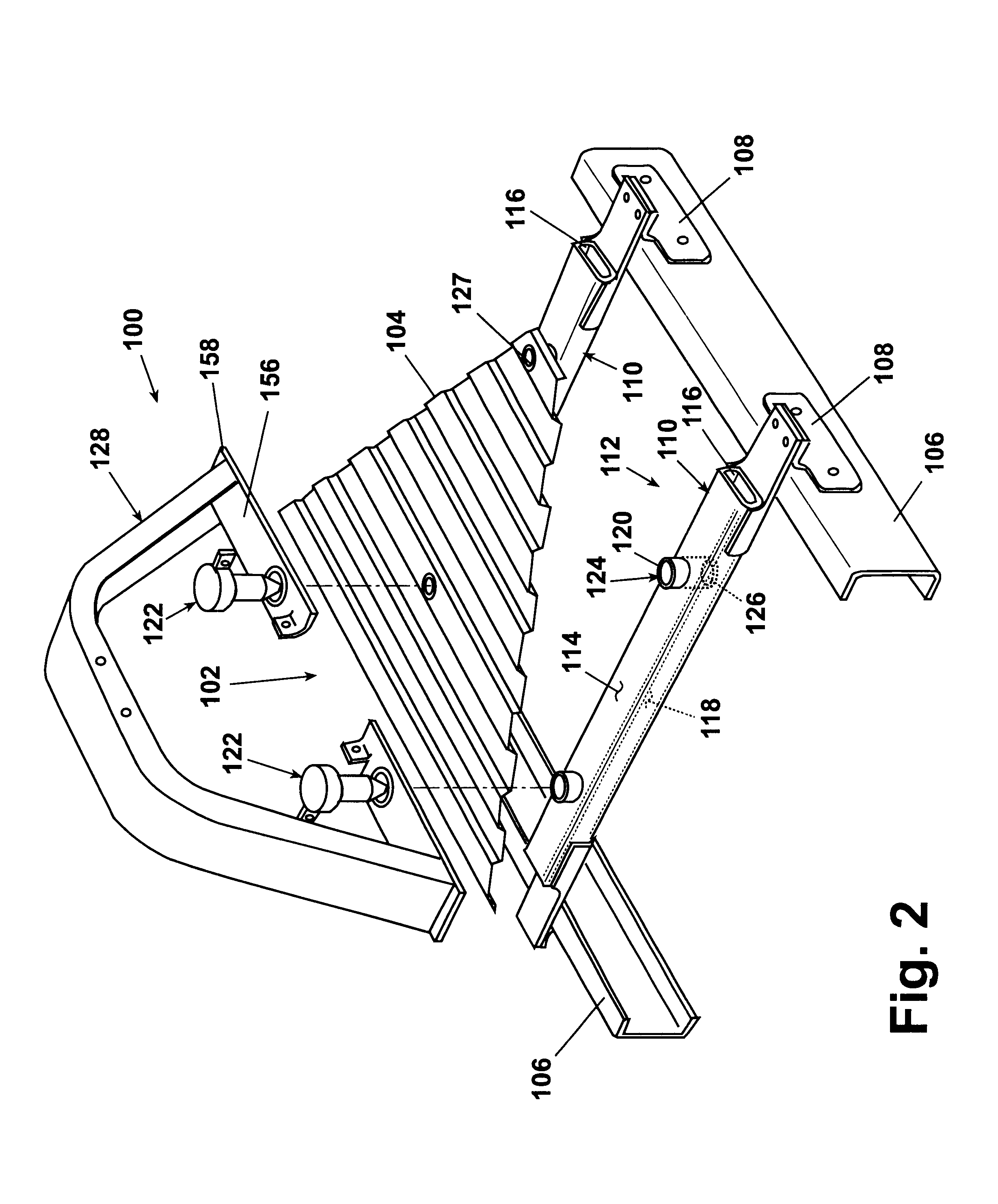

the invention showing an under-bed fifth wheel hitch mounting system 100 is disclosed in FIGS. 2 and 3. System 100 is intended to be installed in a cargo bed area 102 of a utility vehicle such as a pickup truck. Area 102 includes a cargo bed floor 104, secured to two opposed and generally parallel cargo bed vehicle frames 106 forming an integral portion of the entire vehicle. In the illustrated embodiment, frames 106 are C-shaped. Permanently secured through the use of conventional fasteners or welding techniques are a plurality of frame brackets 108. Frame brackets 108 secure at opposite ends a generally hollow tube 110, rectangular in cross-section, and extending generally perpendicularly between frames 106. Two of tubes 110 are illustrated. Frames 106 and tubes 110 are each designed to withstand substantial tensile and compressive loading. They are preferably formed of a traditional iron-based material developed for heavy-duty vehicle use.

When two frames 106 and two tubes 110 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com