Venturi type air distribution system

a technology of air distribution system and venturi type, which is applied in ventilation system, heating type, lighting and heating apparatus, etc., can solve the problems of noisy operation, known system does not use air induction unit for mixing return air and primary air,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

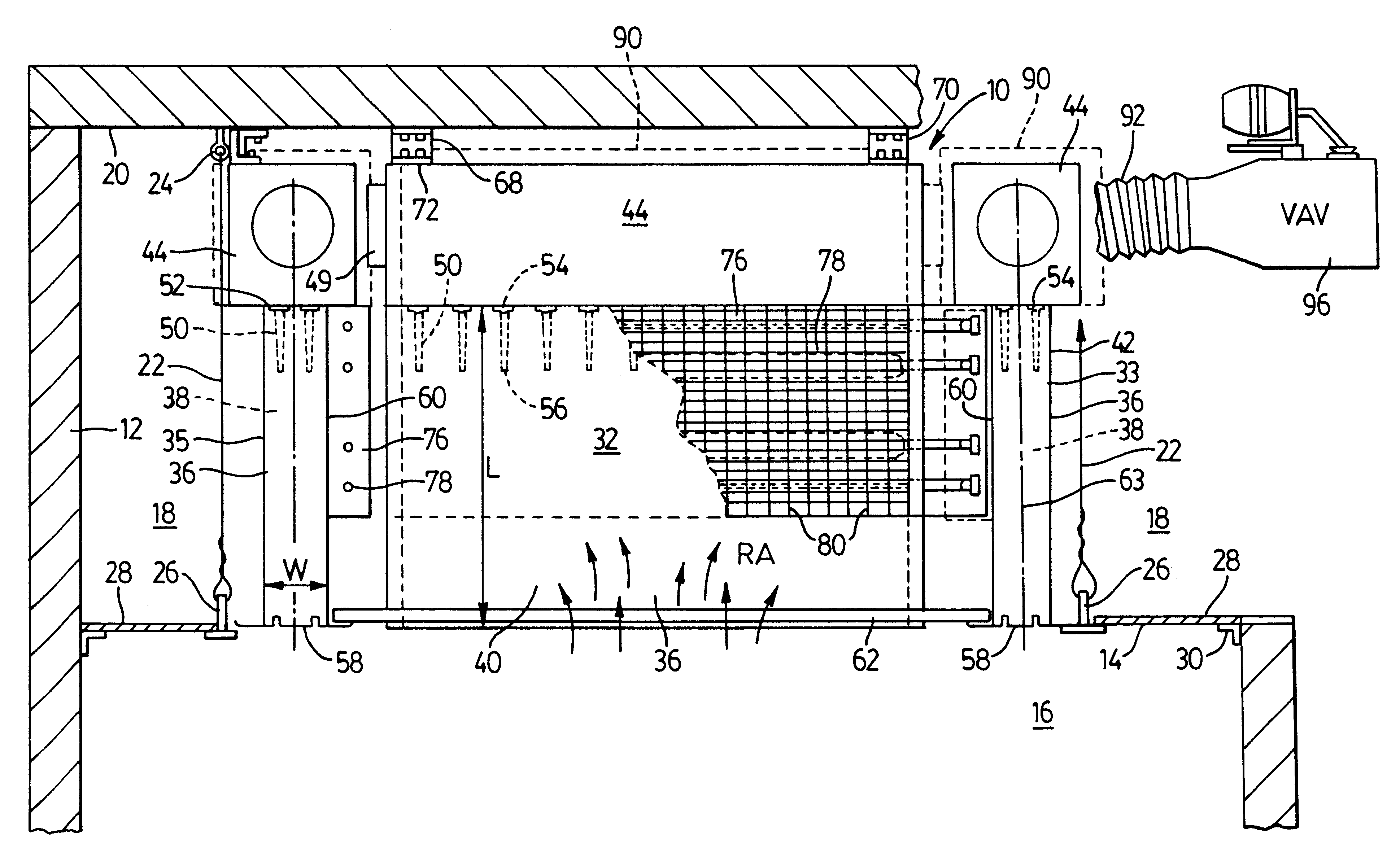

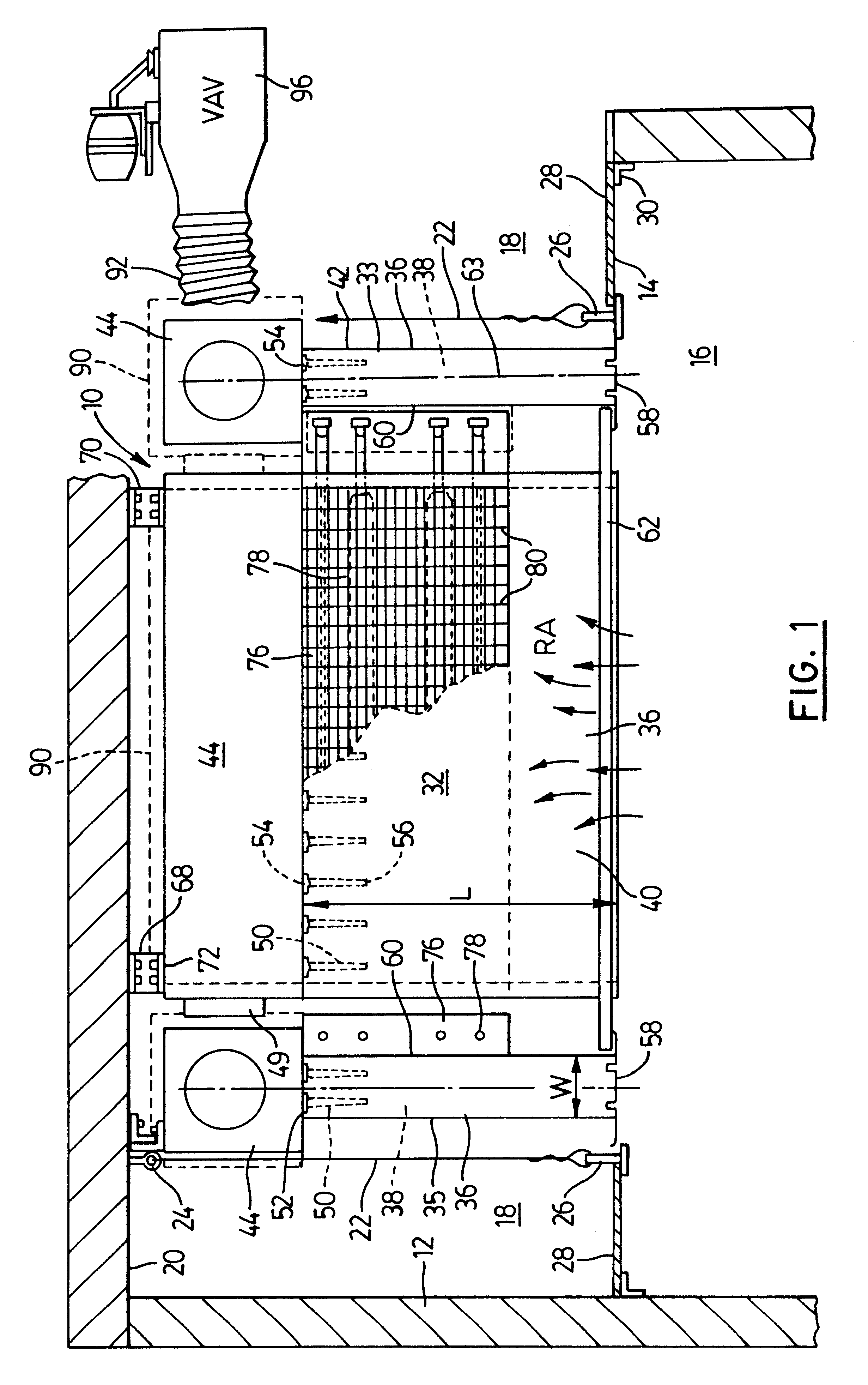

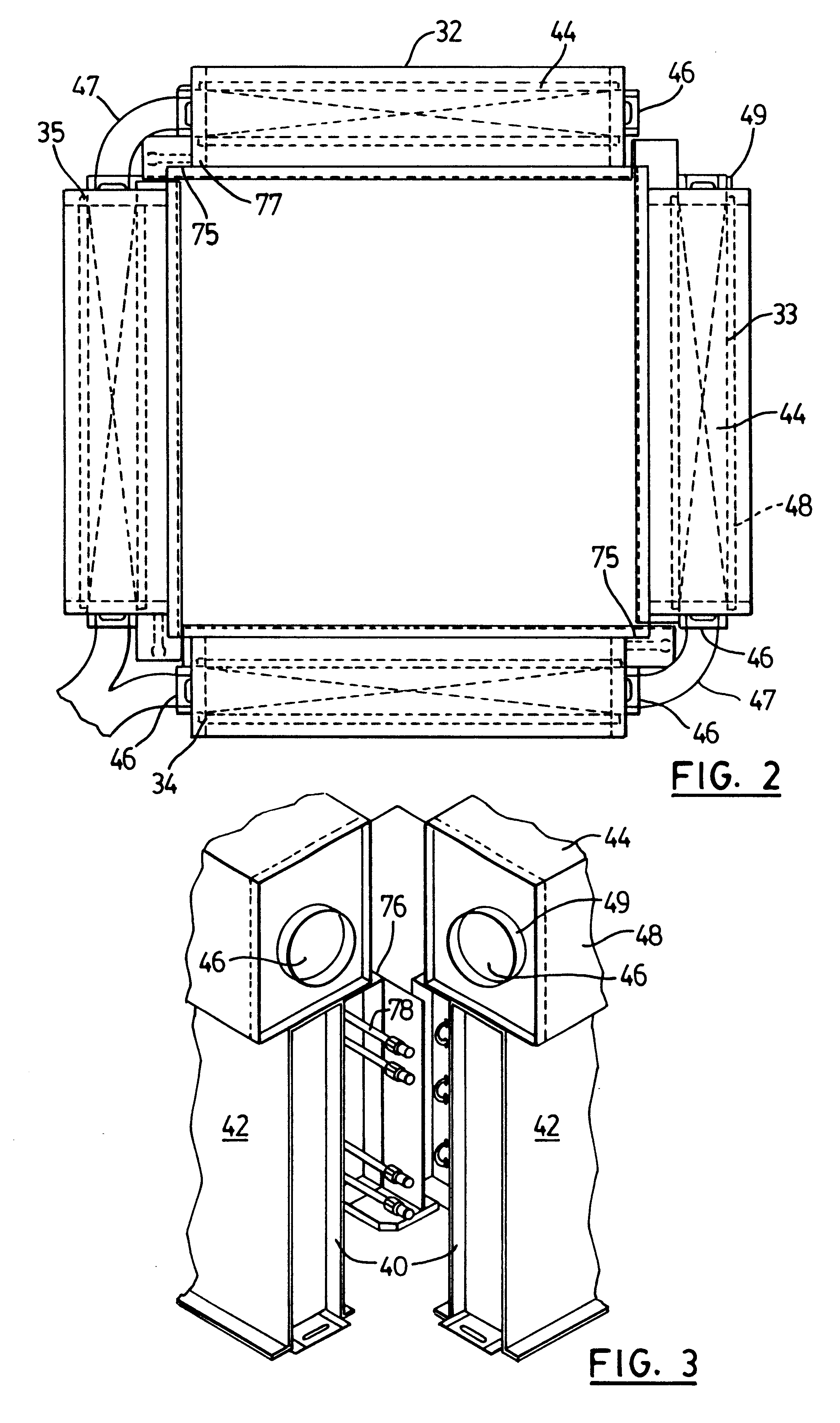

With the induction unit assembly illustrated in FIGS. 1 to 4, a reasonable amount of height is required between the ceiling level at 14 and the structural ceiling at 20 in order to accommodate the height of the induction units. In one typical embodiment of this type of air handling system, the total height of each induction unit assembly is about 23 inches and a small amount of additional room may be required to attach the assembly to the structural ceiling 20. If this much room is not available for the induction unit assembly, then a user of this system can employ the embodiment illustrated in FIGS. 5 to 7 of the drawings. In FIGS. 5 to 7, the same reference numerals will be used to indicate those features which are the same as in the embodiment of the induction unit assembly illustrated in FIGS. 1 to 4. This second embodiment of induction unit assembly is indicated generally at 110. The assembly includes four induction units 112 to 115, each of which has the same height, this heig...

first embodiment

Each of the induction units has an elongate, horizontally extending air plenum section 118. The position of this air plenum section differs from the position of the air plenum section 44 in the first embodiment in that the major section of the plenum section 118 is located on the outer side of the air mixing section 36 rather than above the air mixing section. Each plenum section 118 has a bottom 120 connected to an outer wall 122. The inner wall of the air plenum section is provided by the vertical wall 42 of the air mixing section. At the top of the air plenum section 118 is a connecting duct section 124 that includes a top wall 126, this wall extending over the air mixing section 36. There is a relatively short vertical wall 128 which extends downwardly from the top wall to the top edge of the air mixing section. It will be understood that air is free to flow in the direction indicated by the arrow Z in FIG. 5 from the main portion of the air plenum section 118 into the region di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com