Distributed natural gas storage system(s) using oil & gas & other well(s)

a technology of natural gas and storage system, which is applied in the direction of mining structures, borehole/well accessories, etc., can solve the problems of general over-building of the delivery system, environmental impact, and demand on the delivery system, so as to reduce the cost, increase the ability to meet, and increase the efficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

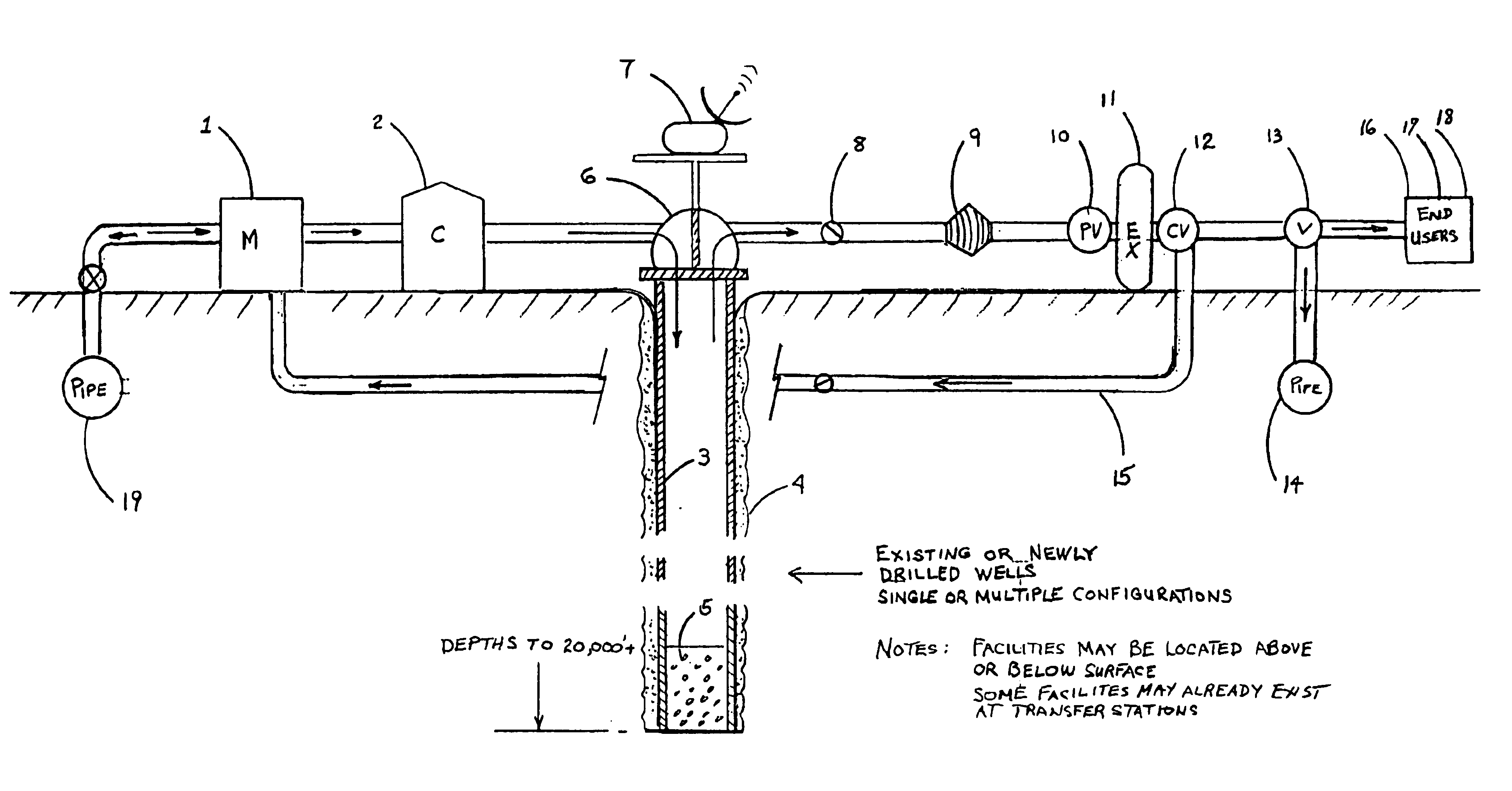

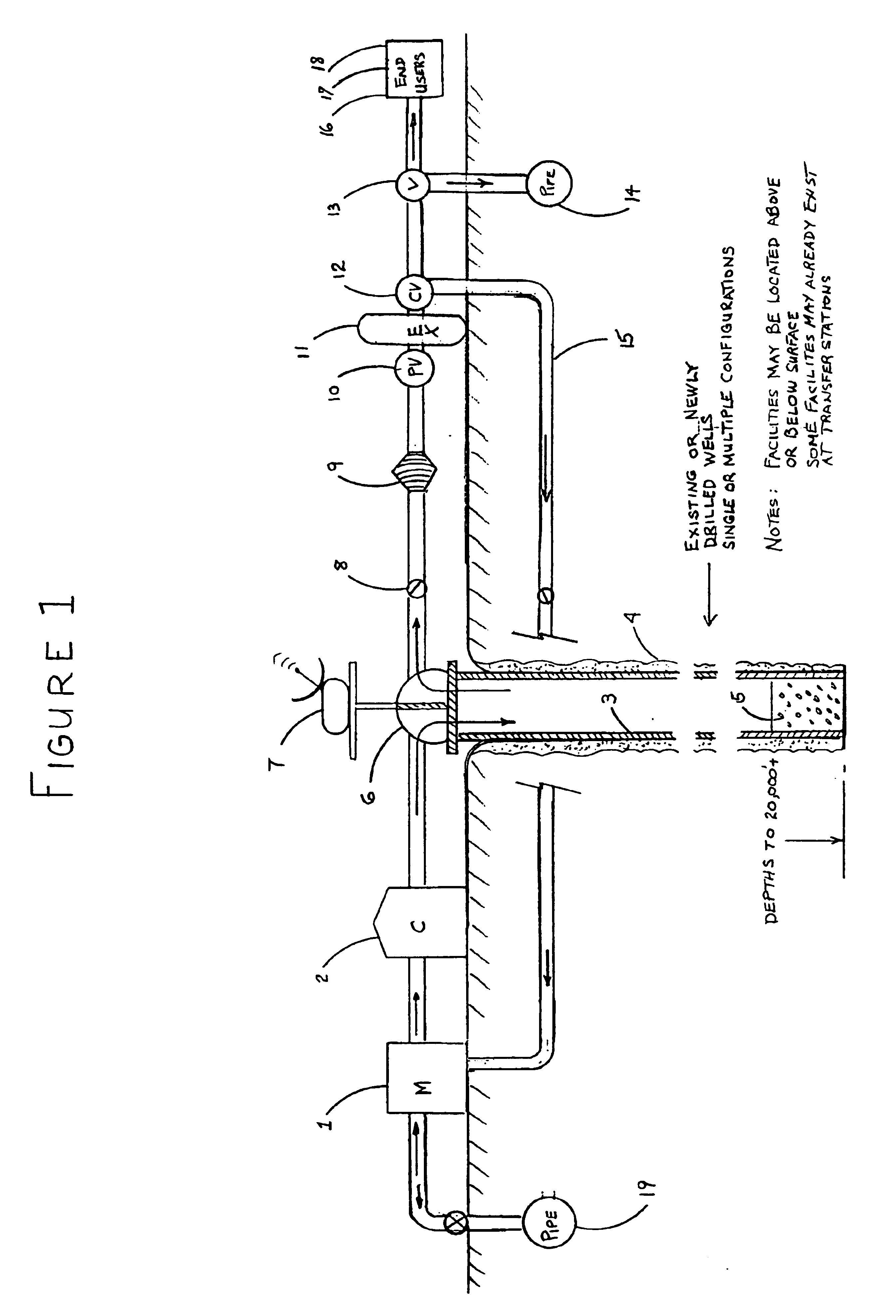

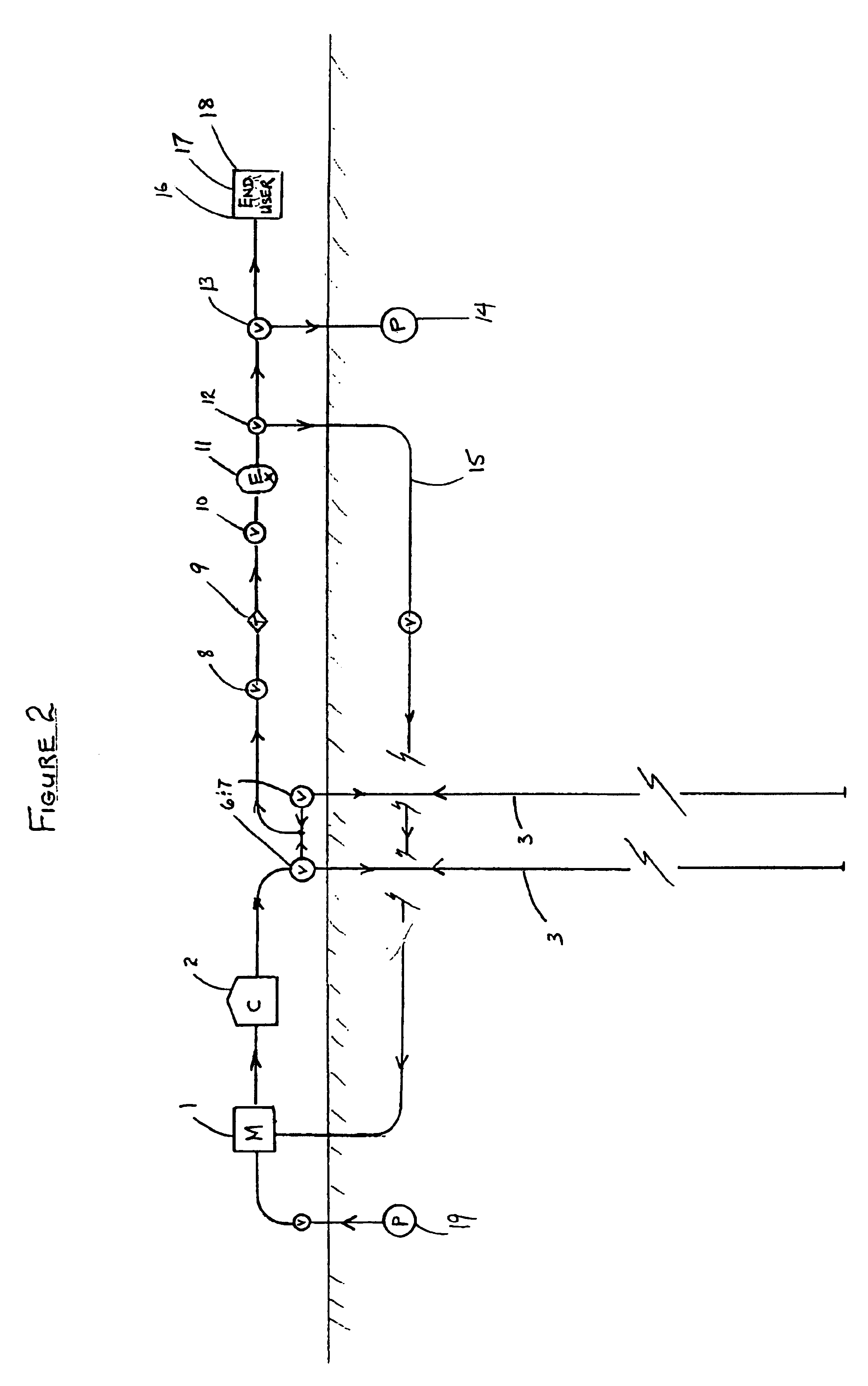

The present invention relates to the new use of drilled oil and gas, or new, to be drilled wells to store and cycle compressed natural gas or other gasses within a specifically designed system(s) whereby the compressed gas is self-contained within the cavity of the well-bore casing and not permitted to be forced through any well-bore casing perforations into the surrounding underground formation due to the fact that the cased well-bore is sealed.

Generally, oil and gas wells are usually drilled to significant depth, greater than 3,000 feet, and then plugged, if dry, or eventually abandoned once production of oil and / or gas stops.

This invention revolves around the use of existing drilled oil and gas well(s), either dry holes, abandoned or converted producing wells and / or new, to be drilled, well(s) or any other well(s) of any depth and any diameter, located, sited, designed, drilled and fabricated to store and cycle compressed natural gas or other gasses, in any volume and with any de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com