Automatic reclosable bag filler

a reclosable bag and automatic technology, applied in the field of vending equipment, can solve the problems of unsatisfactory tap water purity, labor-intensive or unsanitary packaging approach, and difficulty in adjusting the bag mouth, so as to facilitate the operation of the zipper slider and relieve the tension on the bag mouth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

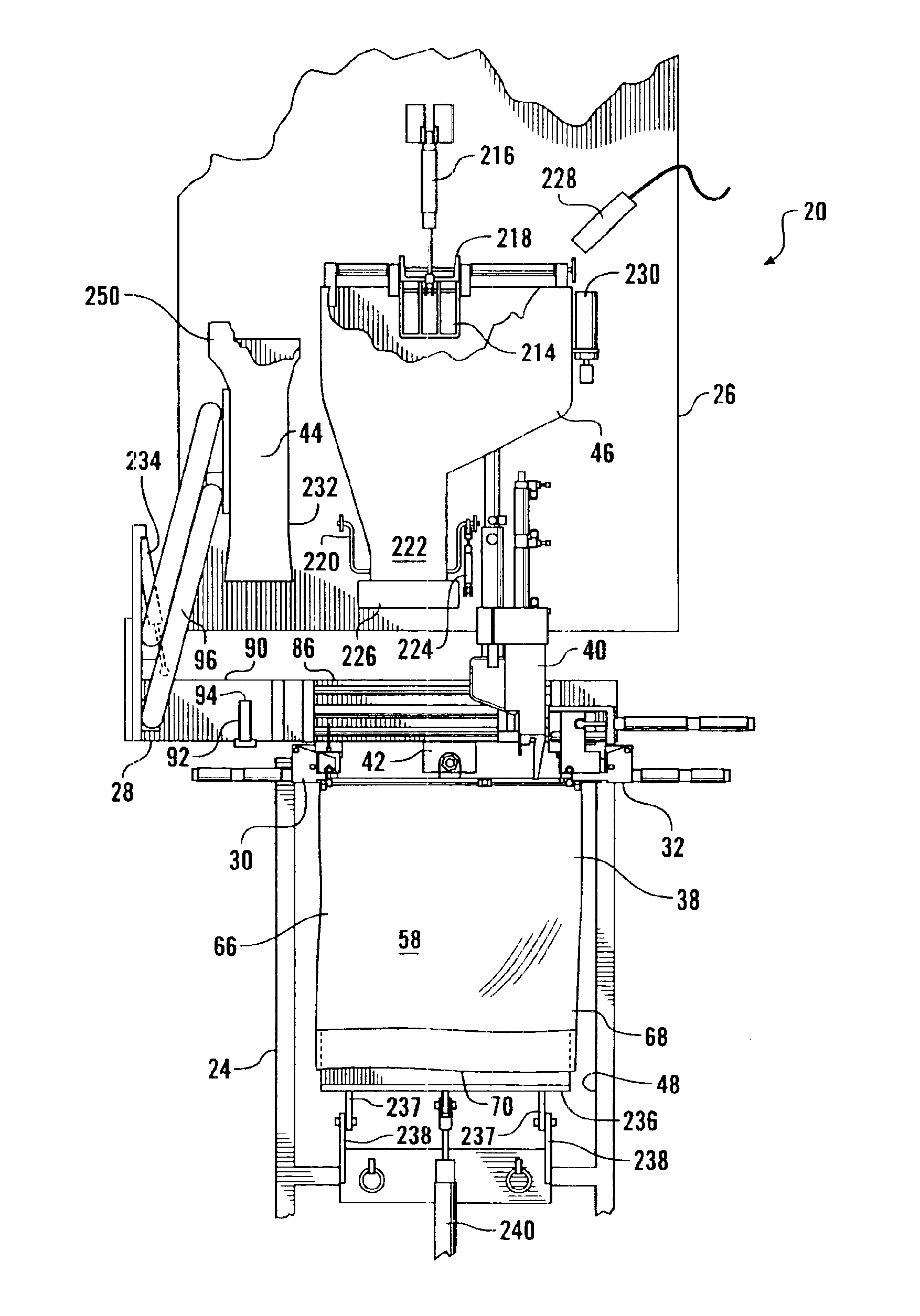

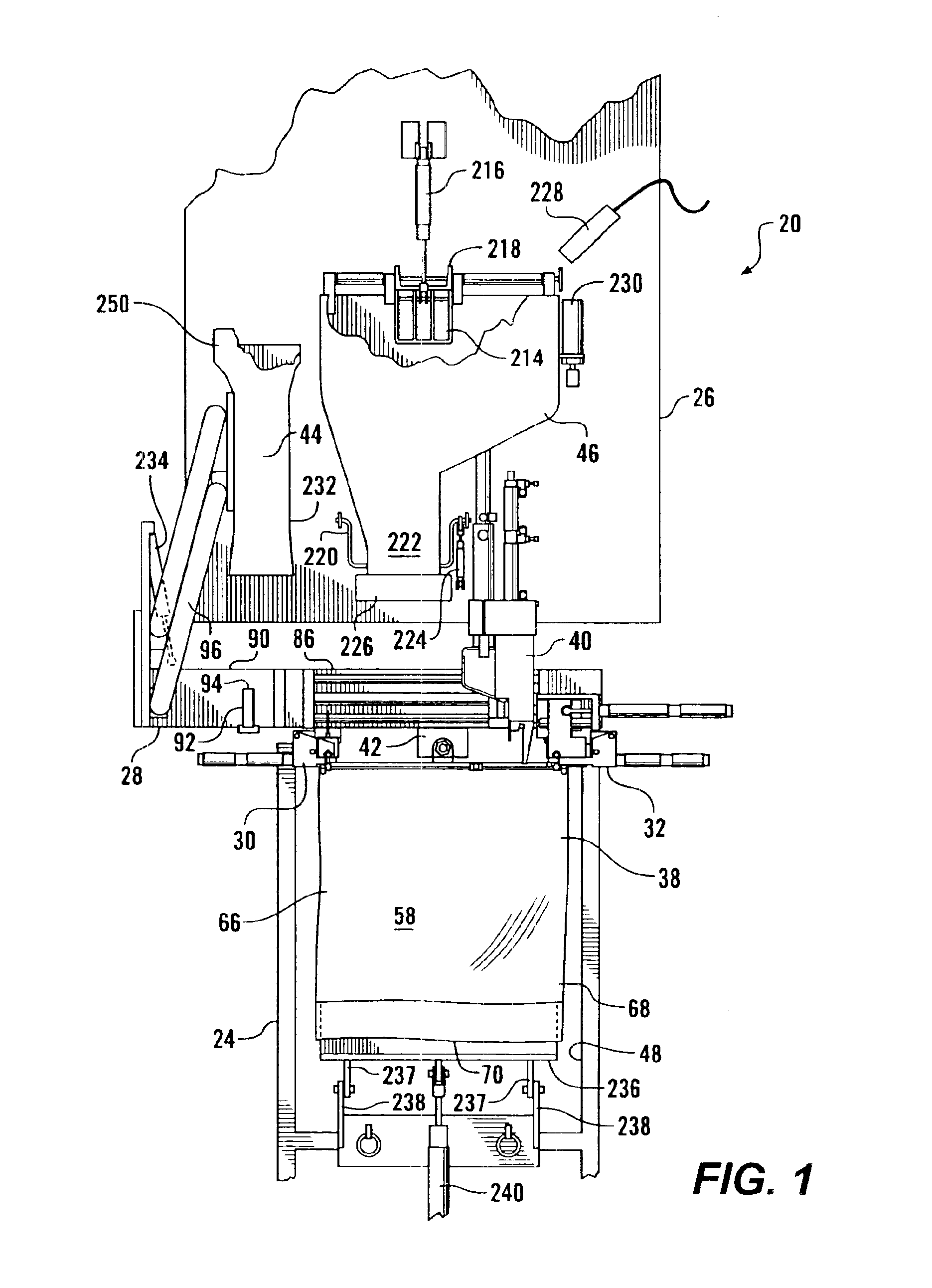

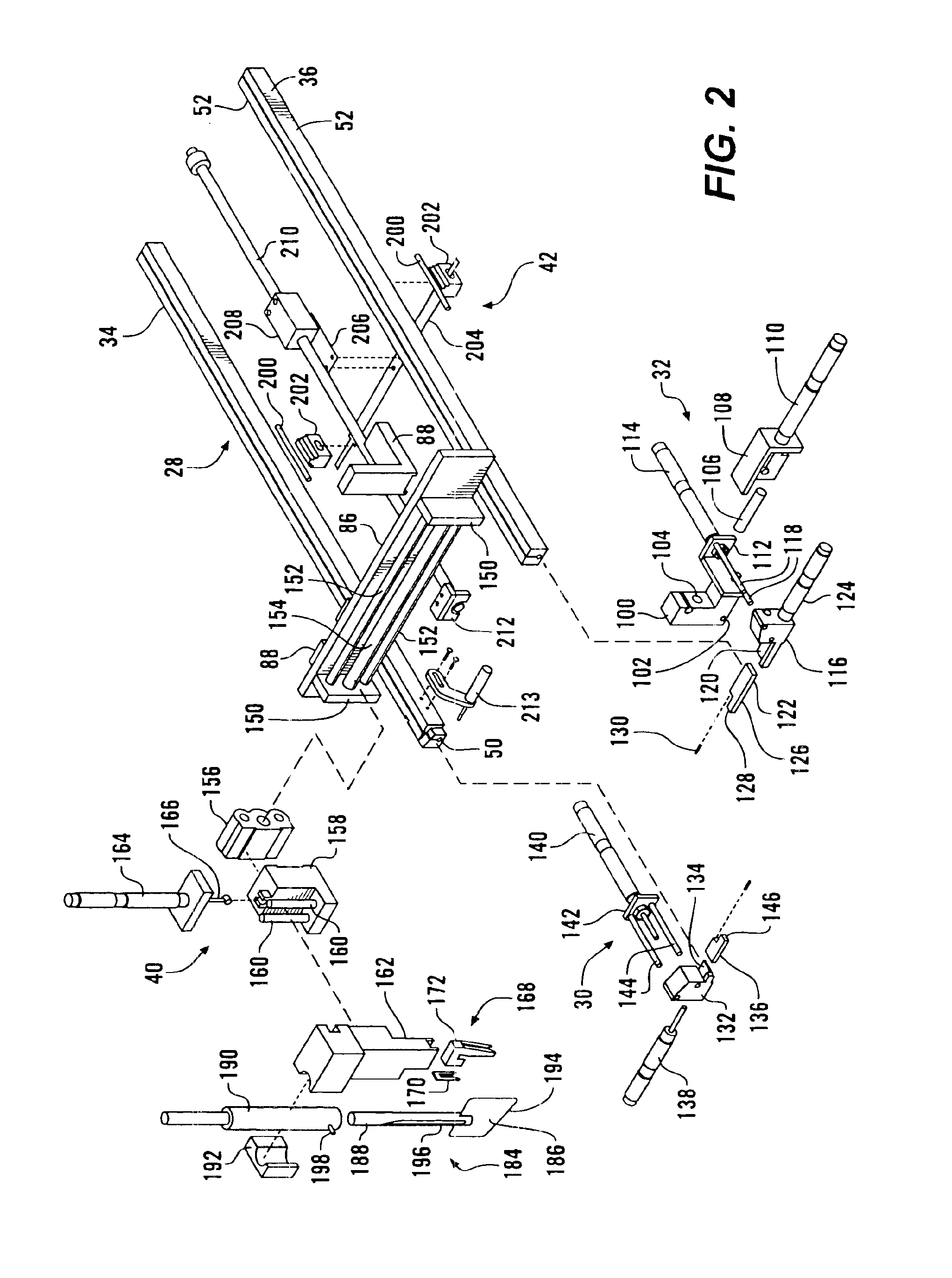

Referring more particularly to FIGS. 1-8, where like numbers refer to similar parts, an automated bagger 20 is shown in FIG. 1. The bagger 20 will be illustrated in an ice bagging environmental, although it should be understood that the apparatus 20 may be used to dispense other product into a bag. The bagger 20 has an insulated housing 22 having an interior metal frame 24. The moving parts of the bagger are mounted to the frame 24. A conventional ice maker 26 is mounted to the upper part of the frame 24, and a subframe assembly 28 is mounted to the frame 24 below the ice maker. The subframe assembly 28 has two parallel rails 34, 36 from which an array of bags 38 are suspended. A left indexer assembly 30 and a right indexer assembly 32 are mounted to the left rail 34 and right rail 36 respectively, and control the position of the edges of the bags 38. The indexer assemblies 30, 32 serve as bag engaging assemblies which hold the sides of the bag and present a selected bag for operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com