Latch timing mechanism for a two-step roller finger cam follower

a technology of roller finger cam follower and latch timing mechanism, which is applied in the direction of valve arrangement, mechanical equipment, machines/engines, etc., can solve the problems and achieve the effect of less rigorous timing of hydraulic pressurizing and depressurizing of latch pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

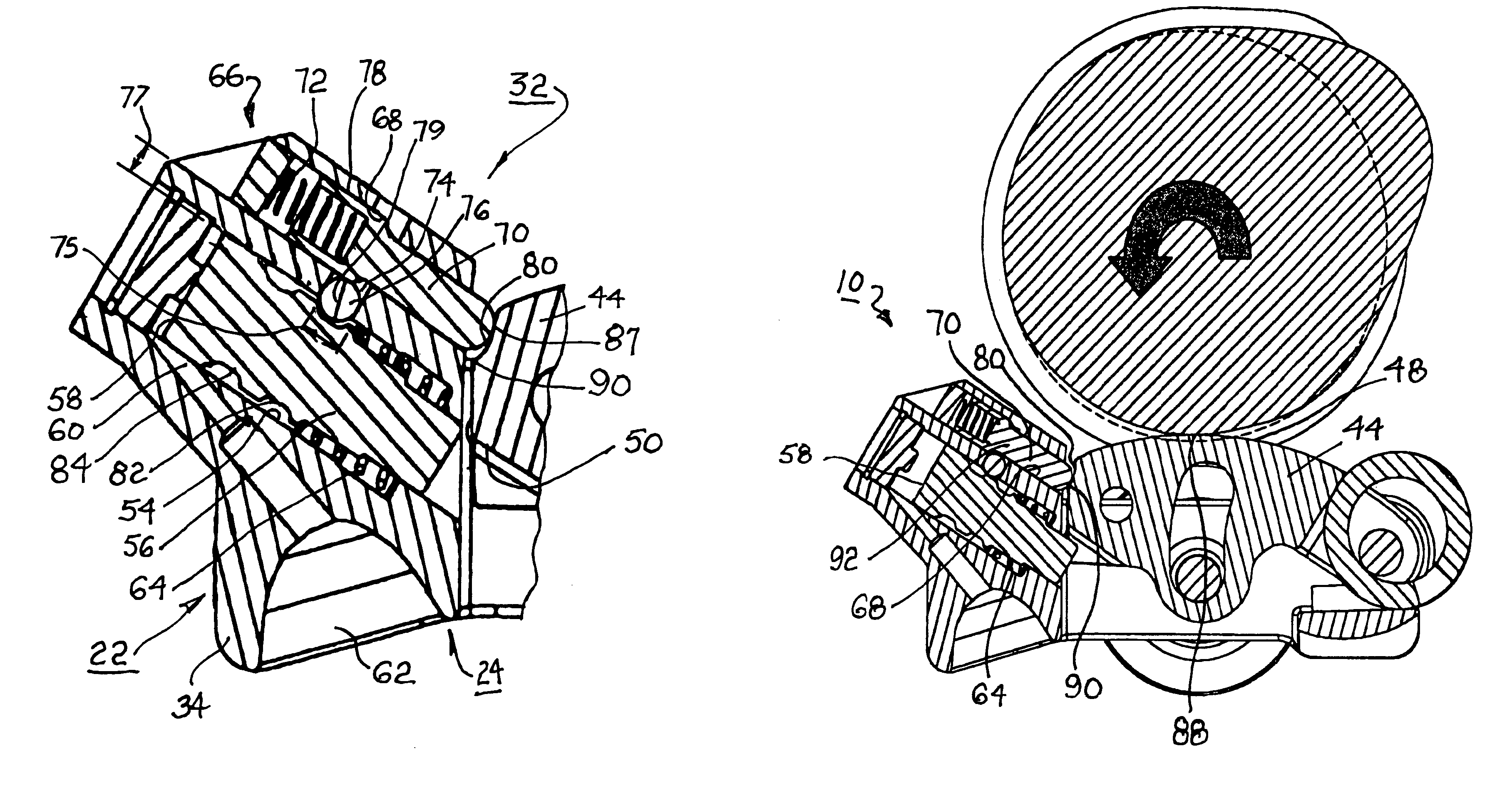

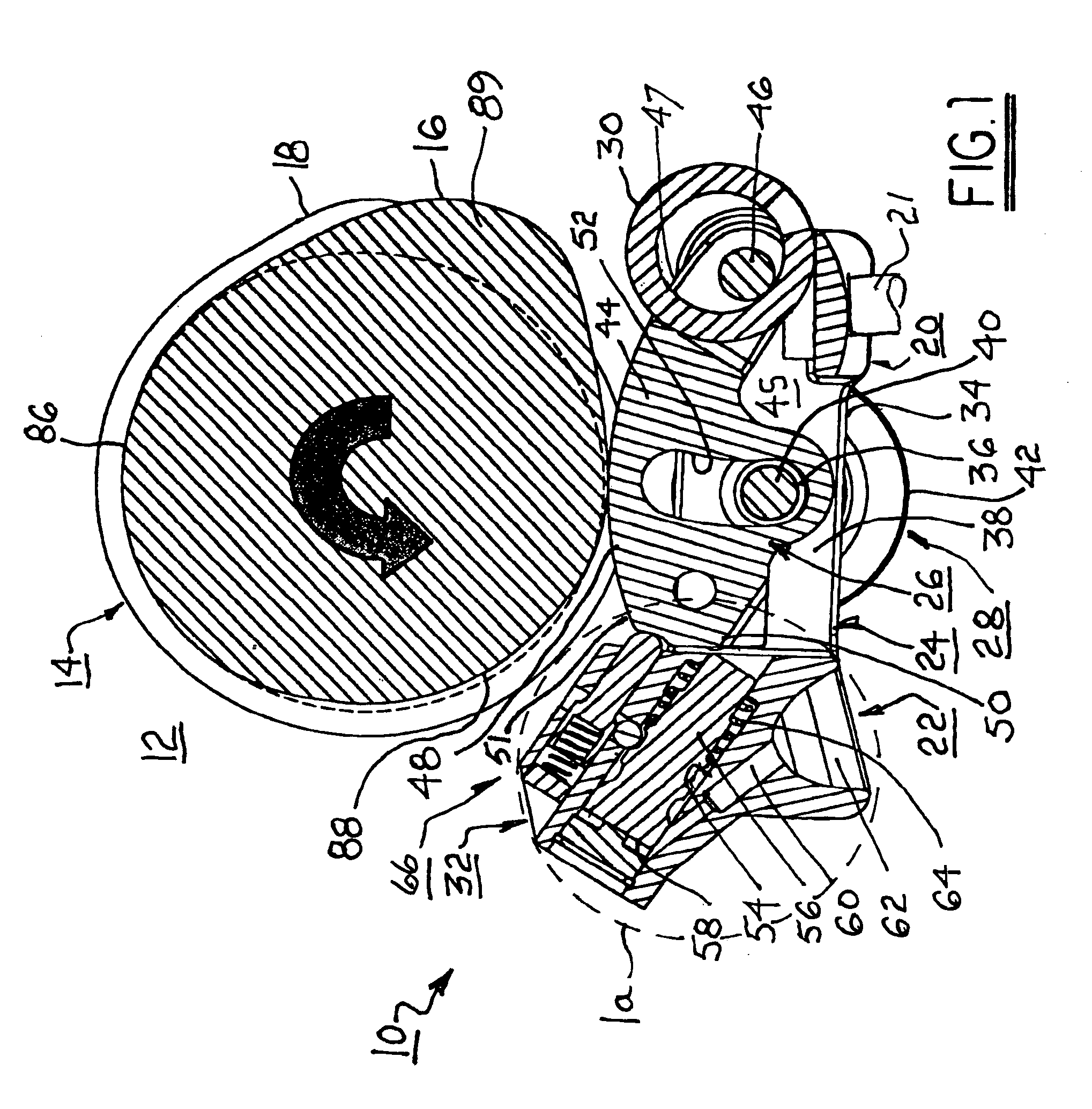

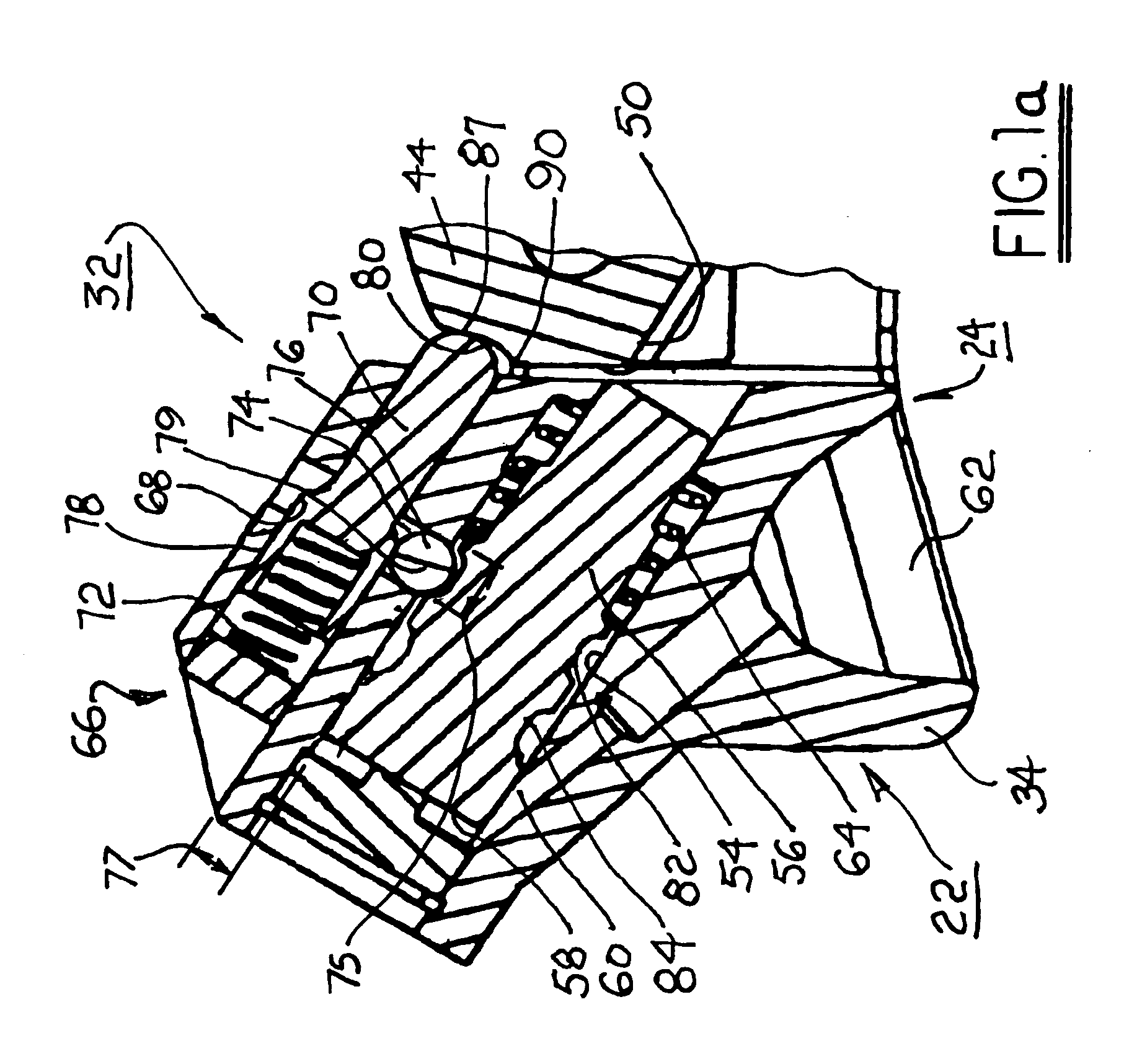

[0017]Referring to FIGS. 1 through 3, improved two-step roller finger follower 10 is shown. RFF 10 is intended for use with an internal combustion engine 12 comprising a cam 14 having a central high-lift lobe 16 flanked by a pair of low-lift lobes 18. High-lift lobe 16 includes base circle portion 86 and positive lift region 89. The high lift lobe is either enabled by latching of a central slider arm 44 pivotable within the RFF, or disabled by unlatching the central slider arm and allowing it to pivotably follow the high-lift lobe in lost motion as further described below.

[0018]Referring to FIG. 1, a pallet end 20 of RFF 10 is provided for engaging a valve stem 21 and a socket end 22 of RFF 10 is provided for engaging the hemispherical head of a hydraulic lash adjuster (not shown) in known fashion, the valve stem and socket head being conventional elements of engine 12. RFF 10 includes body assembly 24, slider arm assembly 26, spool roller assembly 28, lost motion spring 30, and lat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com