Method and apparatus for manufacturing slip stopper

a manufacturing method and slip stopper technology, applied in the direction of load securing, transportation items, transportation and packaging, etc., can solve the problems of noise diffusing, increased production process and cost, and inevitable noise from the engine blowing upward from the cover, so as to achieve great slip stopper effect, easy manufacturing, and great slip stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

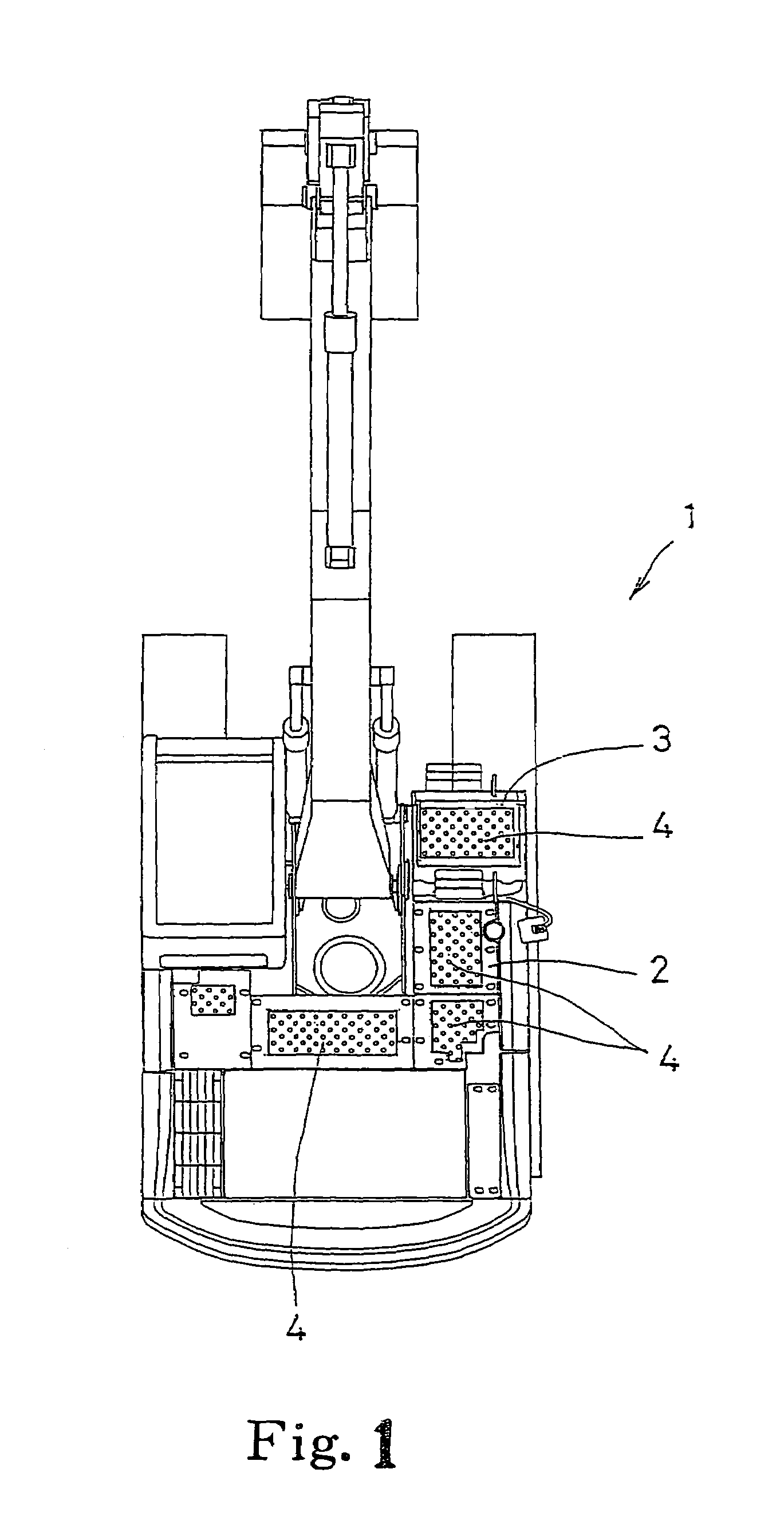

[0025]In the drawings, a construction machine (hydraulic excavator) 1 is constructed so that the upper surfaces of a cover 2 covering the upper surface of the construction machine body and a tool box 3 are formed as stepping surfaces on which a worker walks and steps during maintenance, and a slip stopper 4 to which the invention has been applied is used on these stepping surfaces.

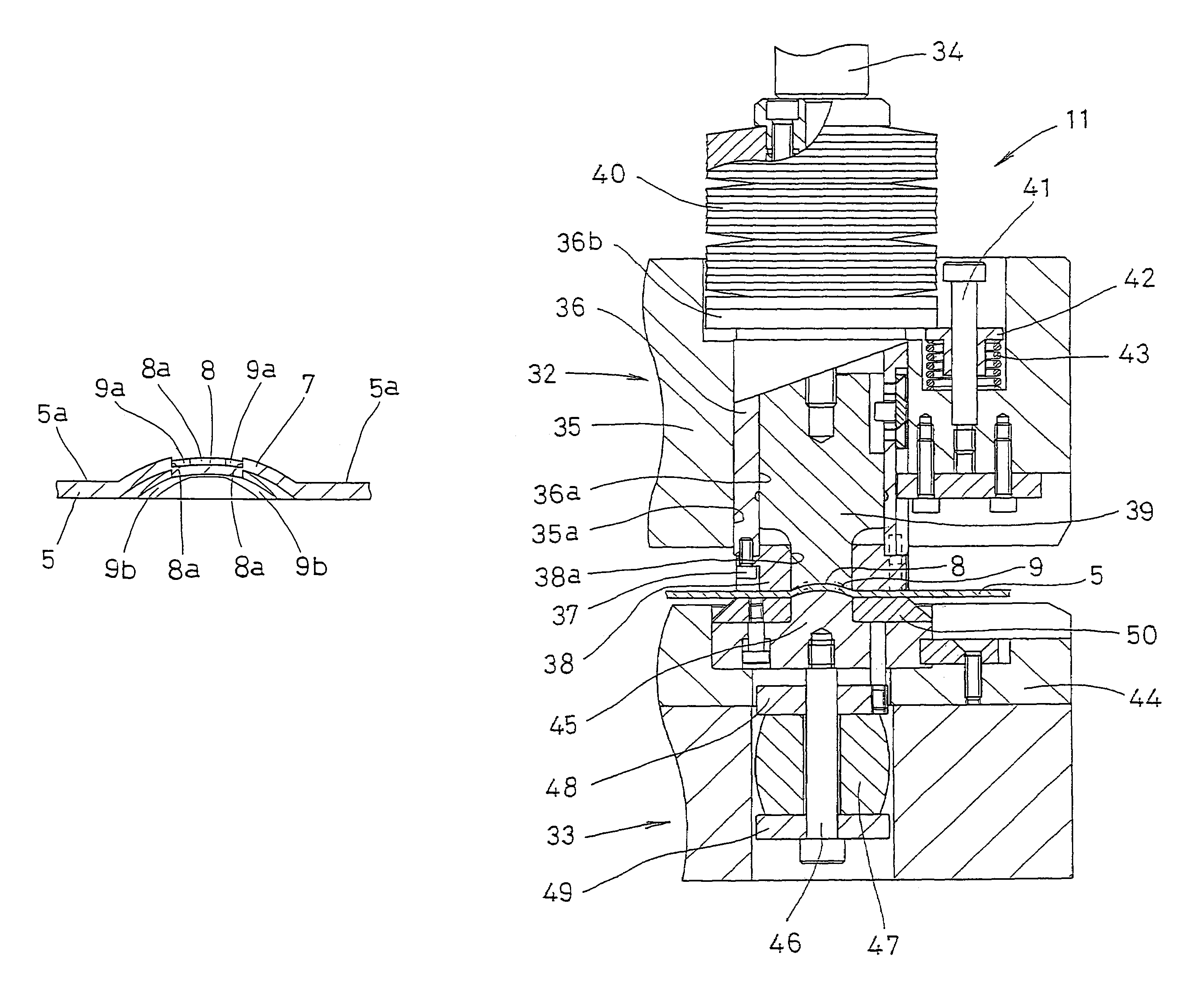

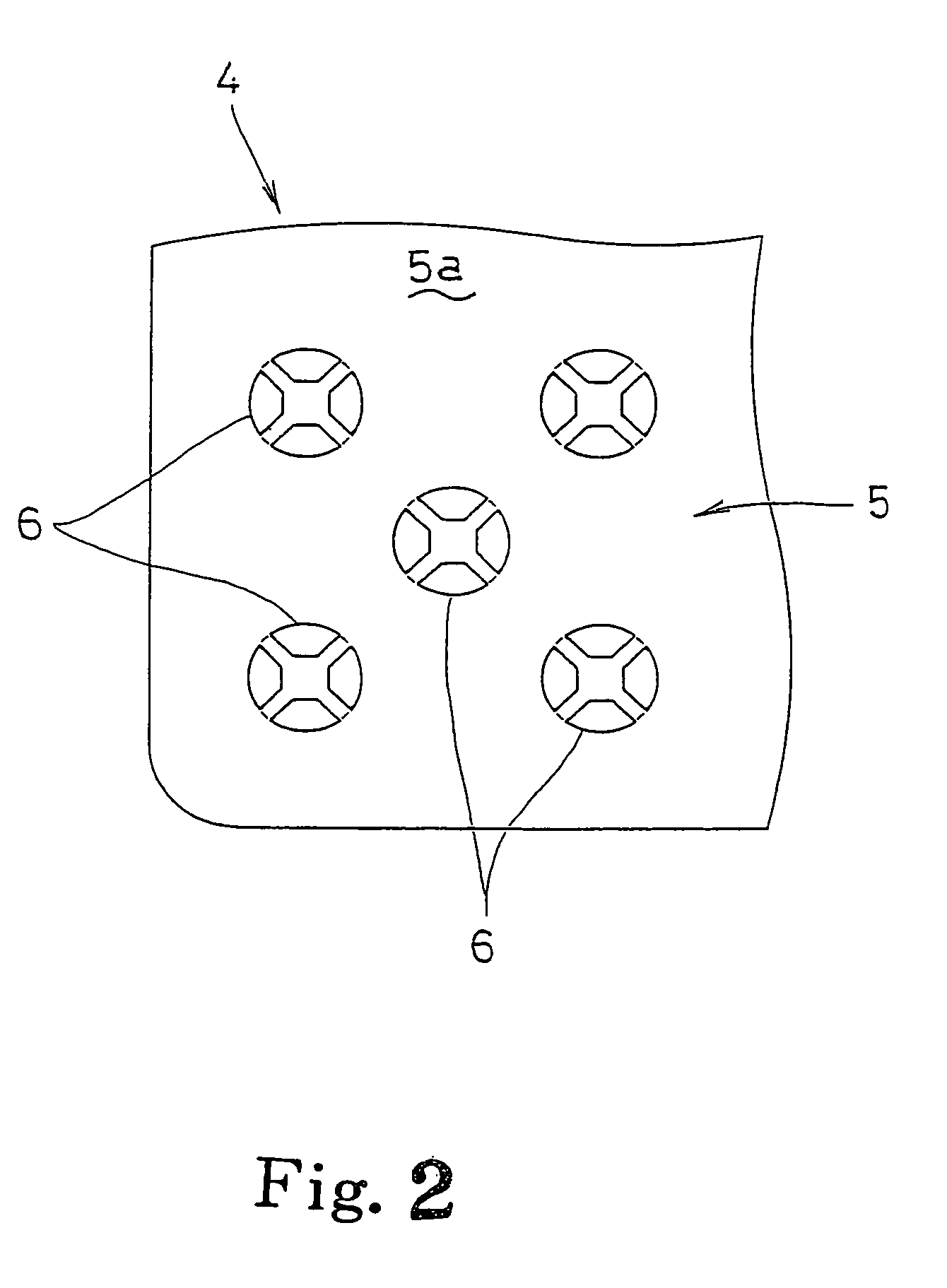

[0026]The slip stopper 4 (FIGS. 2–3(C)) has a plurality of slip stopping parts 6 formed in a vertically and horizontally running pattern on a flat steel plate 5. In the slip stopping parts 6, a concave portion 8 and drain channels 9 are formed in a protruding portion 7, that protrudes in the plate thickness direction from the upper surface 5a of the steel plate 5, by shear planes 8a, 9a described later.

[0027]Namely, the protruding portion 7 is circular in a plan view and has a roughly arc-shaped section. A roughly quadrilateral concave portion 8 is formed at the central portion of the upper surface side of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com