Radiant tube and convection oven

a technology of convection oven and radiant tube, which is applied in the direction of drying machines, furnaces, lighting and heating apparatus, etc., to achieve the effect of preventing overheating of light metal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

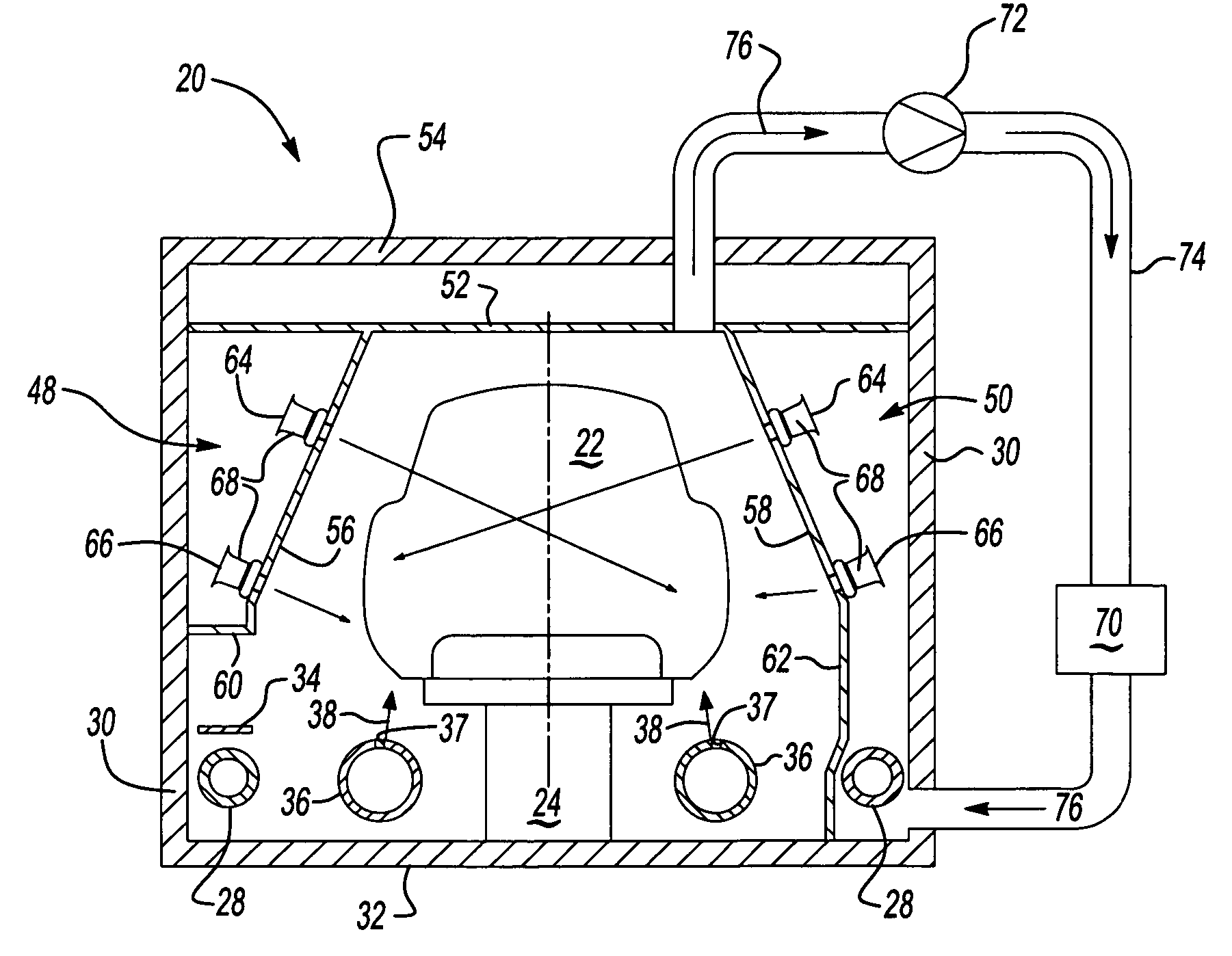

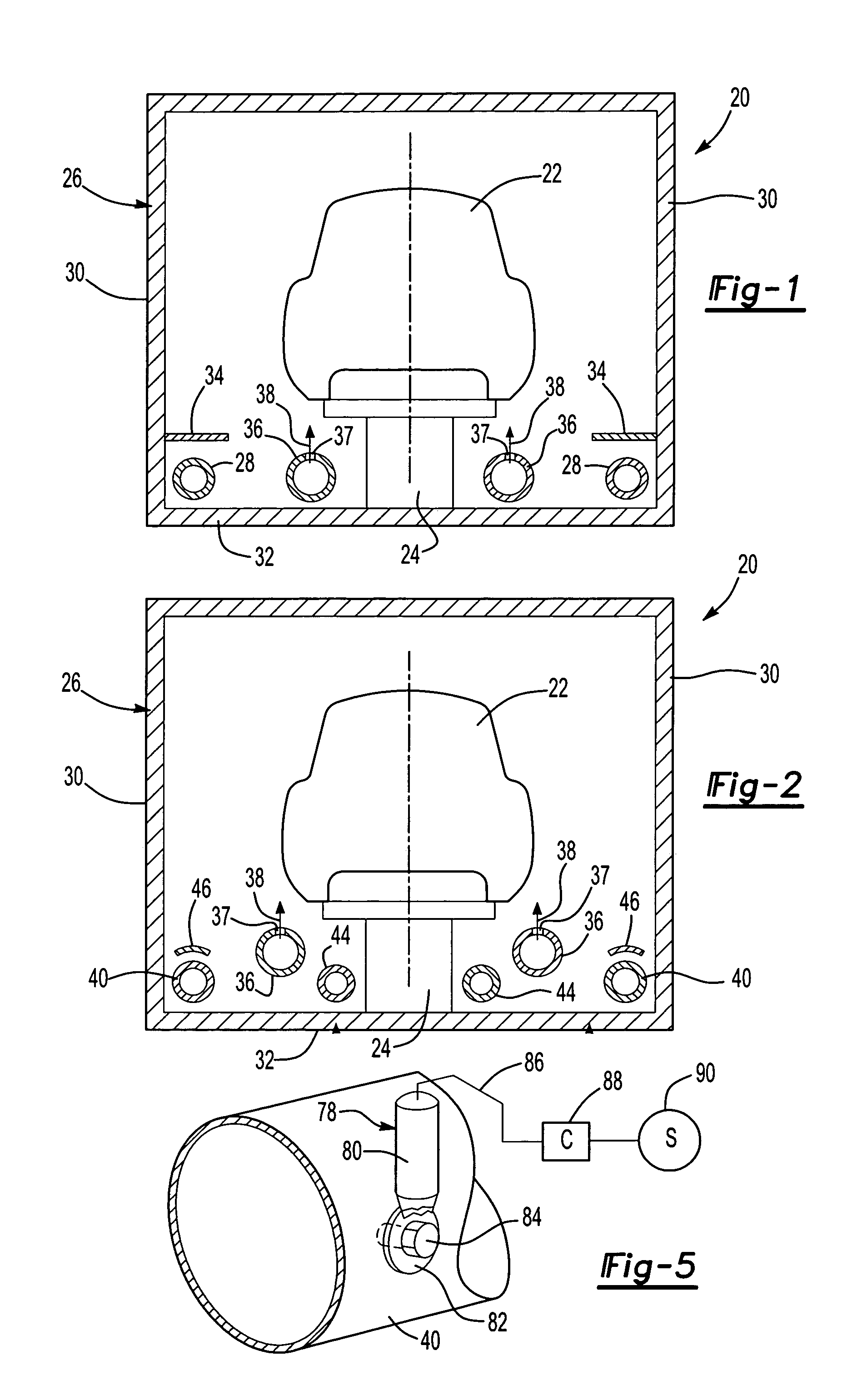

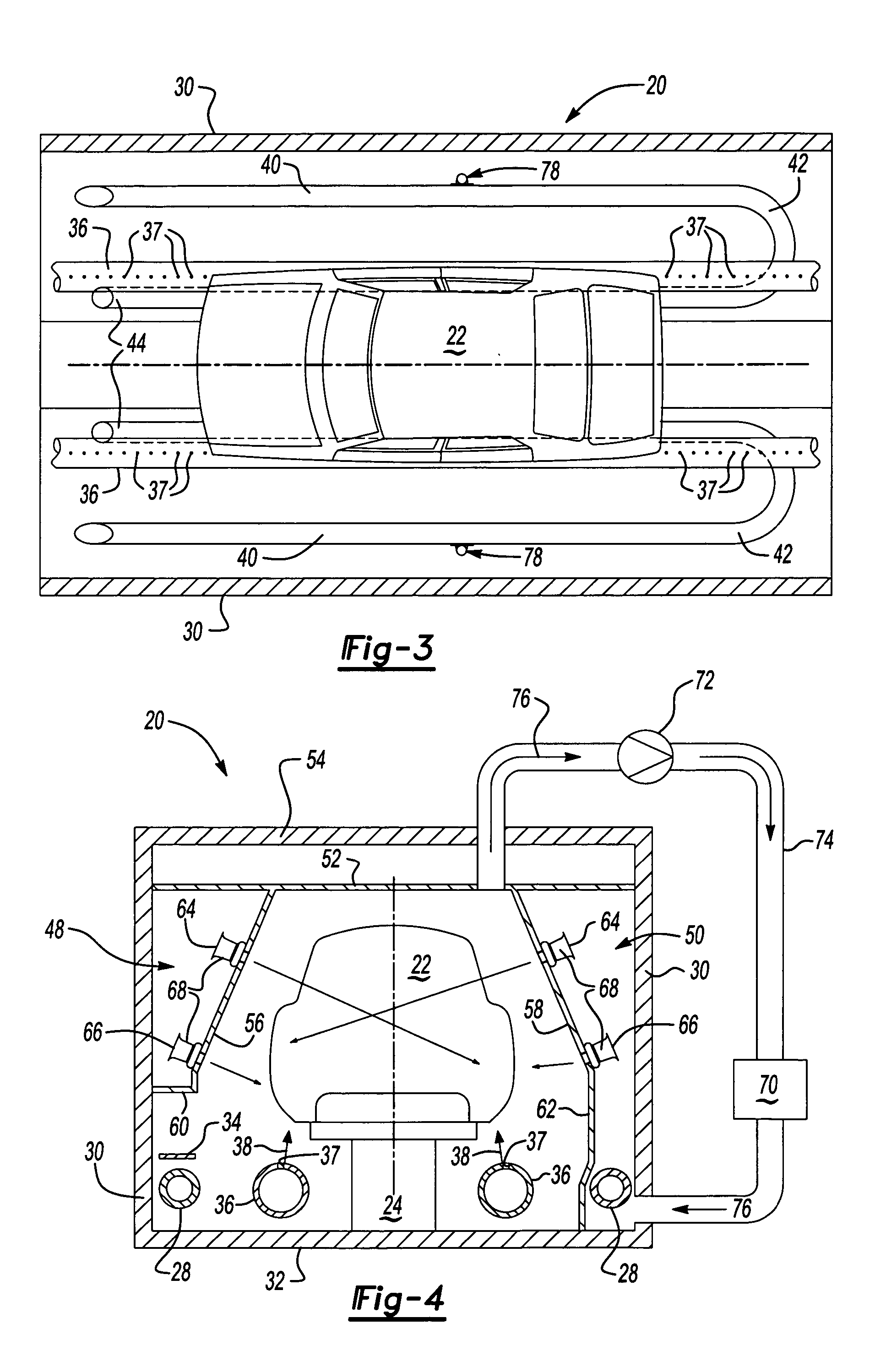

[0018]The radiant tube and convection oven 20 of this invention may be utilized to cure or bake paint or other coatings on various substrates, such as a automotive body or substrate 22, which are conveyed through the oven 20 on a conveyor 24 generally through the longitudinal axis of the oven 20. The radiant tube and convection oven 20 of this invention includes three zones, including a radiant bring-up zone, a convection or convective bring-zone and a hold zone. In a preferred embodiment, the three zones are coaxially or linearly aligned, such that the outer wall 26 of the oven 20 encloses all three zones and the conveyor 24 conveys the automotive body 22 through all three zones of the oven 20. As will be understood by those skilled in this art, however, the radiant tube and convection oven 20 of this invention may include more than three zones, but preferably includes at least three zones.

[0019]FIG. 1 illustrates one embodiment of the first zone of the radiant and convection oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com