Vorticity cancellation at trailing edge for induced drag elimination

a technology of induced drag and vorticity, applied in the direction of propellers, air-flow influencers, transportation and packaging, etc., can solve the problems of reducing the effective angle of attack, not contradicting, and unable to terminate the vorticity, so as to achieve the effect of increasing suction power and potential saving thrust power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

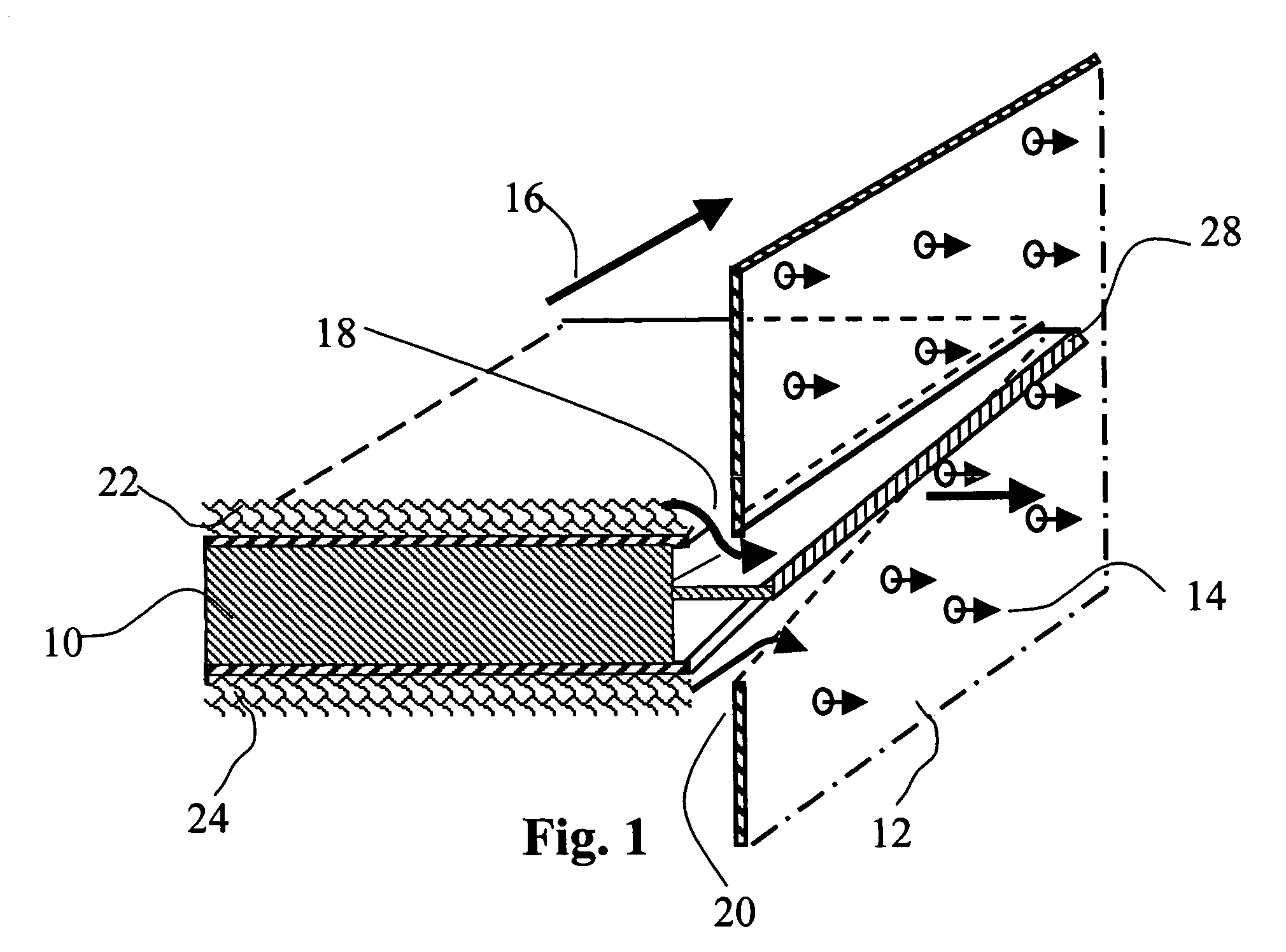

[0046]FIG. 1 shows the trailing edge segment of a 2-D wing 10 mounted in a wind tunnel, between two opposing walls. To achieve true 2-D loading and performance on this wing, the following methods have been applied. Numerous small holes 14 have been drilled through the tunnel wall 12 with the proper level of vacuum applied to remove only the tunnel boundary layer so as to maintain a uniform lift generating relative wind 16 over the wing. Boundary layer control by suction is applied to assure that the bound circulation contained within the boundary layer, remains aligned in the span-wise direction. The upper boundary layer 22 is removed through upper slot 18 while the lower boundary layer 24 through lower slot 20 at the intersection between the airfoil and the tunnel wall. This assures uniform 2-D loading of the wing along its entire span. To prevent short-circuiting of the higher-pressure air below the wing to the lower pressure air above the wing, suction slots 18 and 20 are separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com