Microelectronic packages and methods therefor

a technology of microelectronics and packages, applied in the direction of individual semiconductor device testing, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of imposing stress on solder, terminals moving relative to the contact, assembly including packages can suffer stress, etc., to achieve high reliability, facilitate flexing of the substrate and movement of the posts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

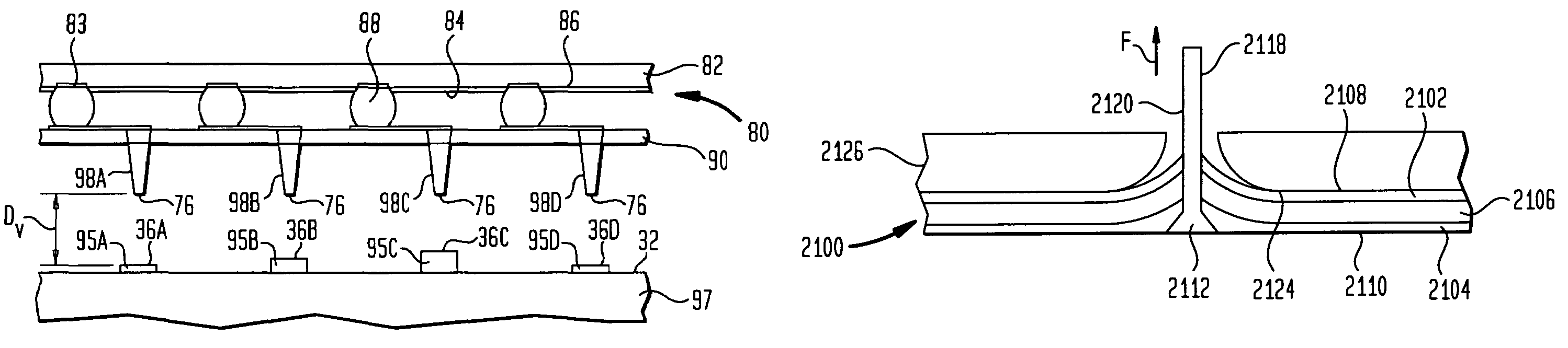

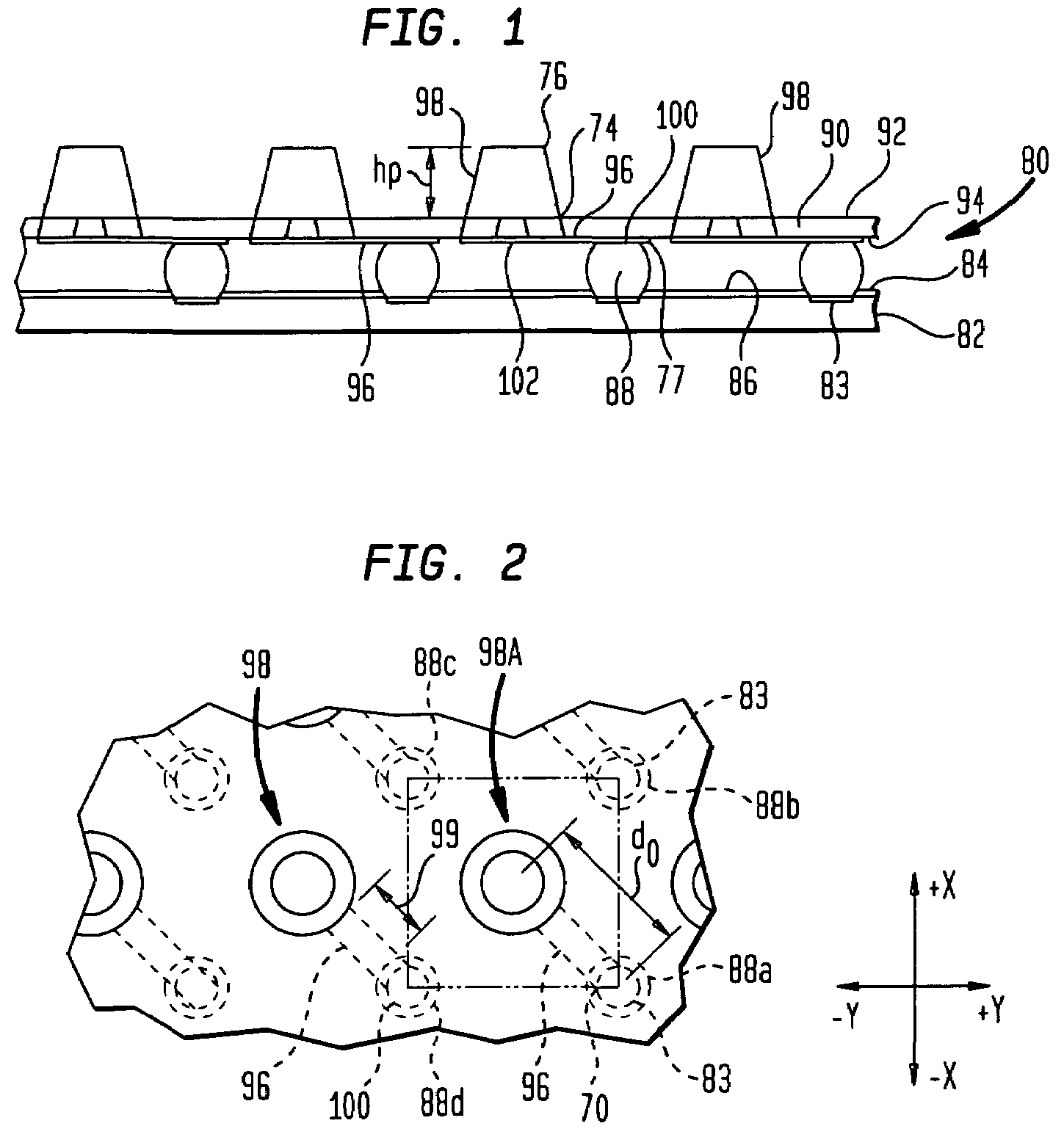

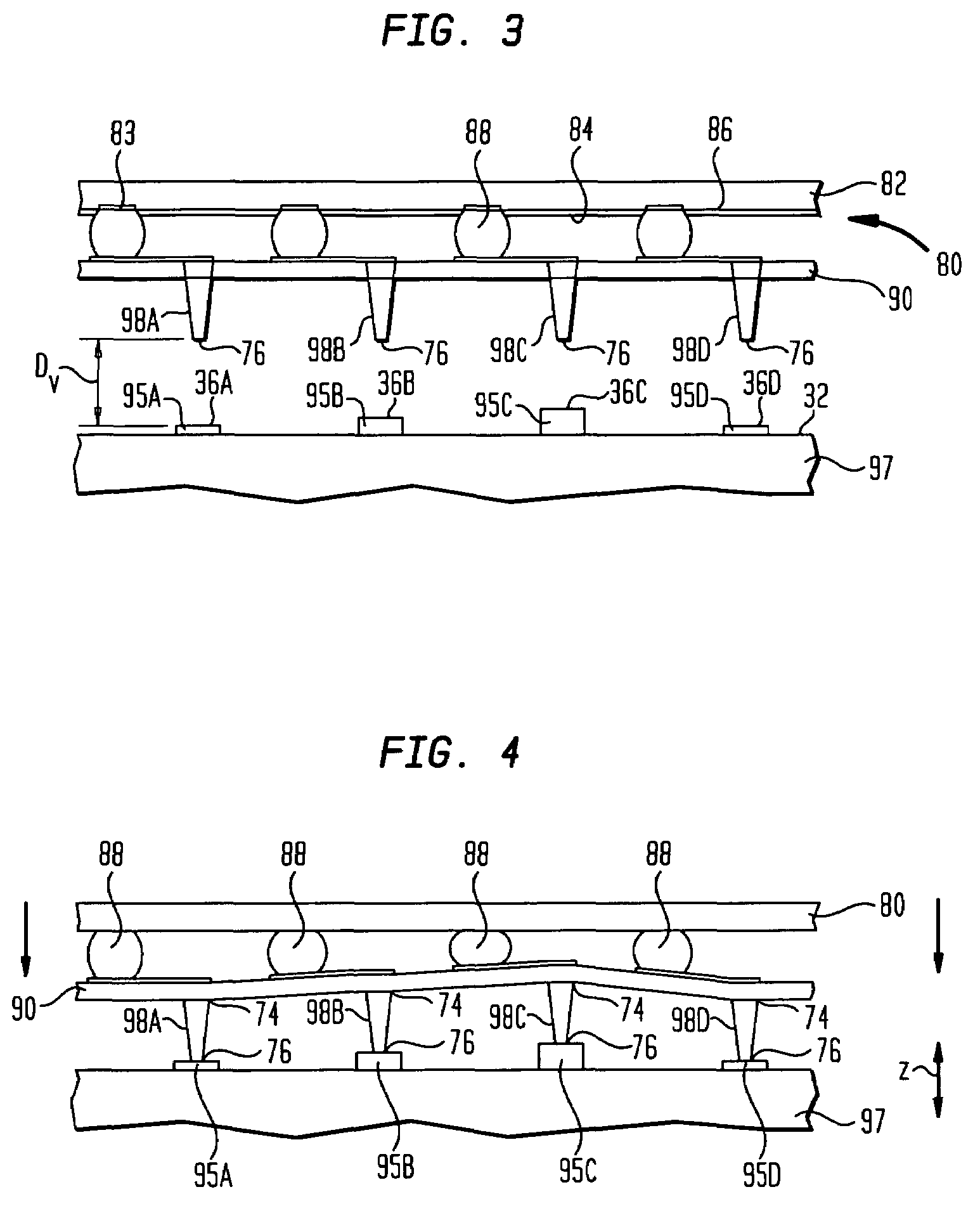

[0041]A microelectronic package 80, in accordance with one embodiment of the present invention, includes a microelectronic element, such as a semiconductor chip 82, having a front or contact bearing face 84 and electrical contacts 83 exposed at face 84. A passivation layer 86 may be formed over the contact bearing face 84 with openings at contacts 83.

[0042]The microelectronic package 80 also includes conductive support elements 88 such as solder balls in substantial alignment and electrically interconnected with contacts 83. As best seen in FIG. 2, contacts 83 and support elements 88 are disposed in an array which in this case is a rectilinear grid, having equally spaced columns extending in a first horizontal direction x and equally spaced rows extending in a second horizontal direction y orthogonal to the first horizontal direction. Each contact 83 and support element 88 is disposed at an intersection of a row and a column, so that each set of four support elements 88 at adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com