Automated induction systems and methods for mail and/or other objects

a technology of induction system and mail, applied in the field of automatic induction system and methods for mail and/or other objects, can solve the problems of imposing a set of repetitive motions, requiring substantial manual loading and tending of operators, and requiring substantial manual processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]While the present invention may be embodied in many different forms, a number of illustrative embodiments are described herein with the understanding that the present disclosure is to be considered as providing examples of various principles of the invention and such examples are not intended to limit the invention to preferred embodiments described herein and / or illustrated herein.

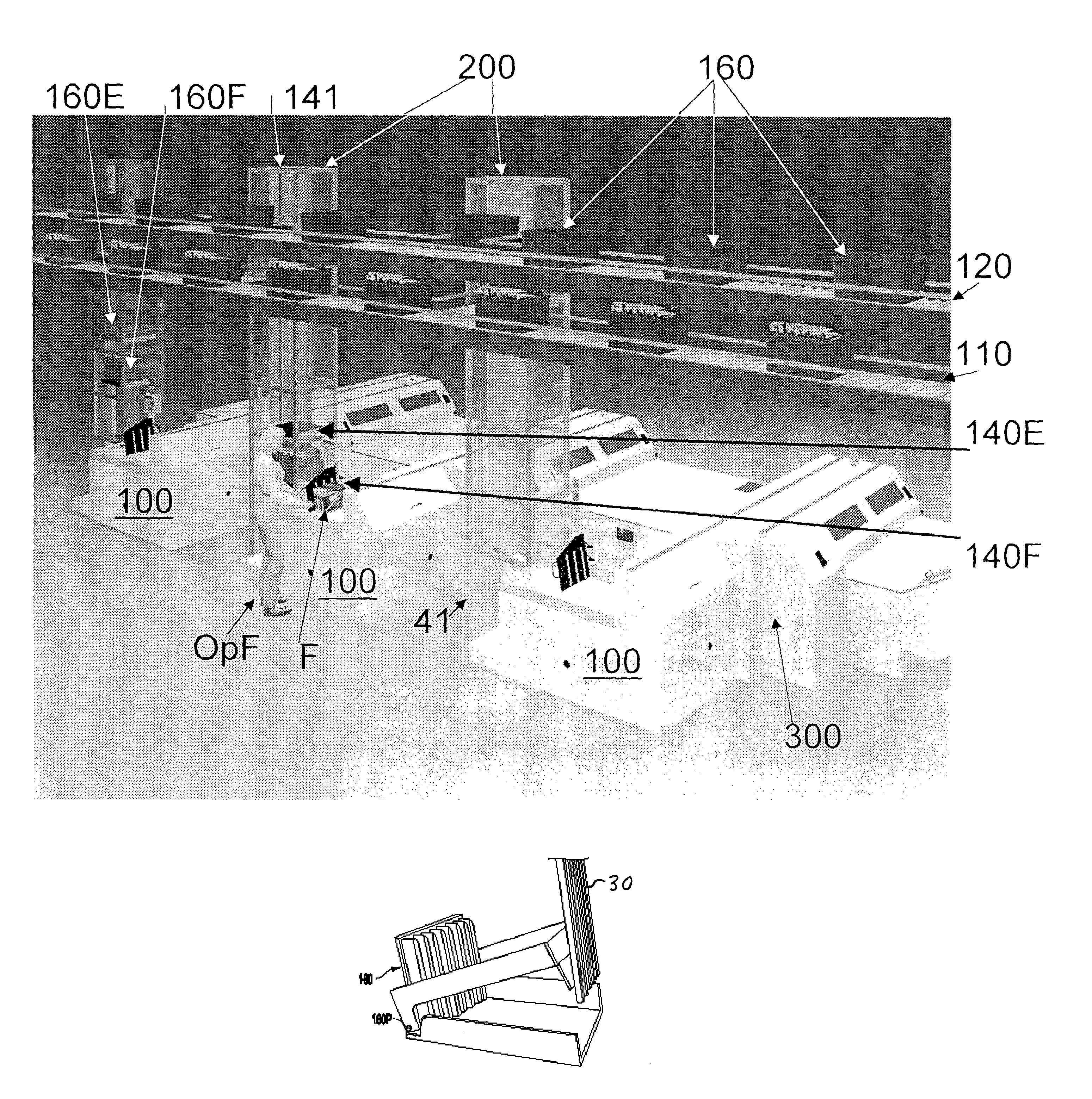

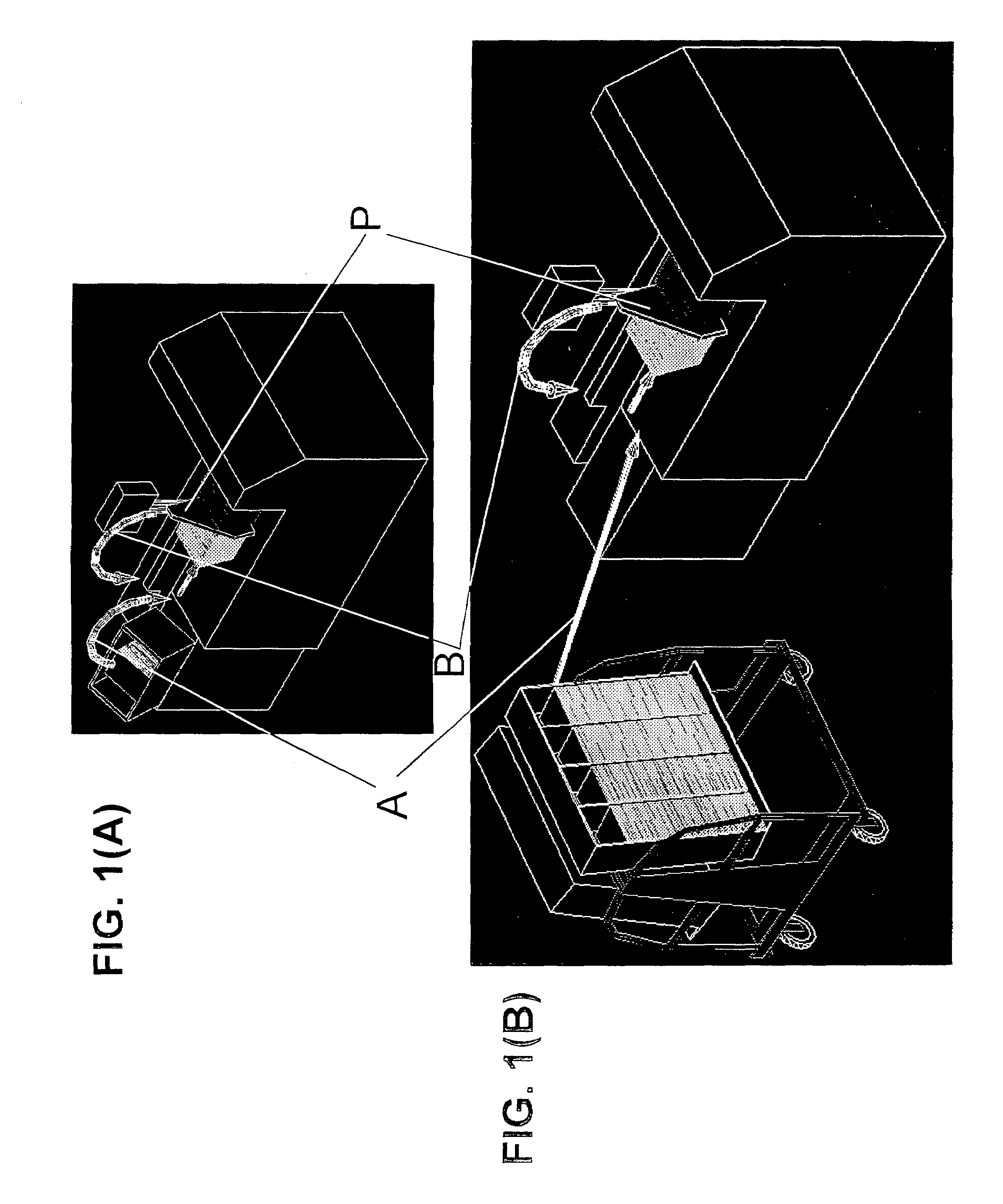

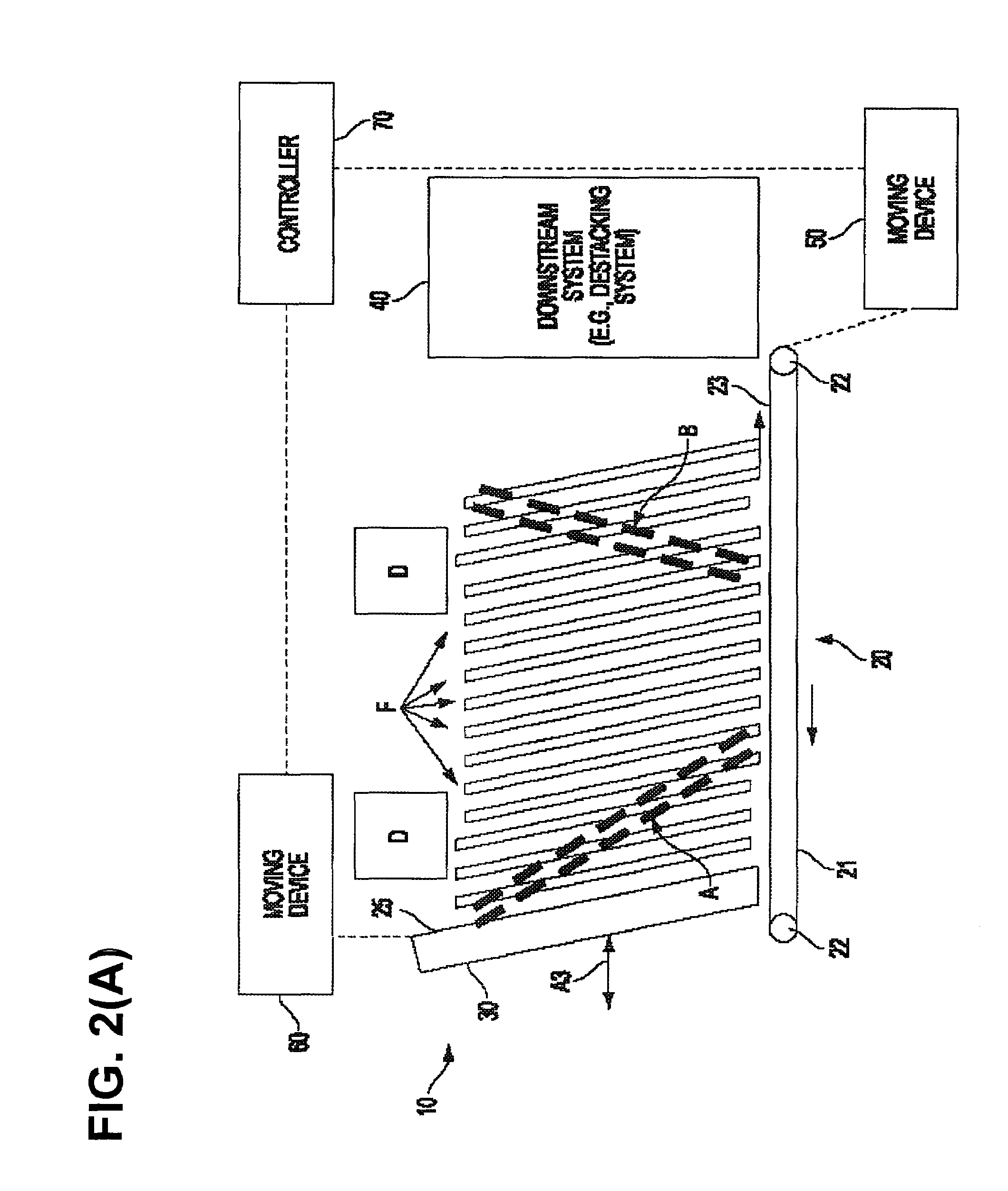

[0048]The preferred embodiments can provide, among other things, a substantially or entirely automated system for use in the processing of thin objects (including, e.g., three-dimensional objects having a size in first dimension that is substantially smaller than sizes in second and third dimensions). While the preferred embodiments can be used to process mail (including, for example, flats, envelopes, letters, postcards and / or other mail), and the most preferred embodiments can be used to process mail flats, various embodiments can also or can alternatively be used to process other thin objects, su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com