Offshore windmill electric generators

a technology for electric generators and offshore windmills, applied in machine supports, machines/engines, liquid fuel engines, etc., can solve the problems of vibration of the structure, the addition of installation cost of the structure is of paramount importance, and the problem of another problem with the electric generators of offshore windmills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

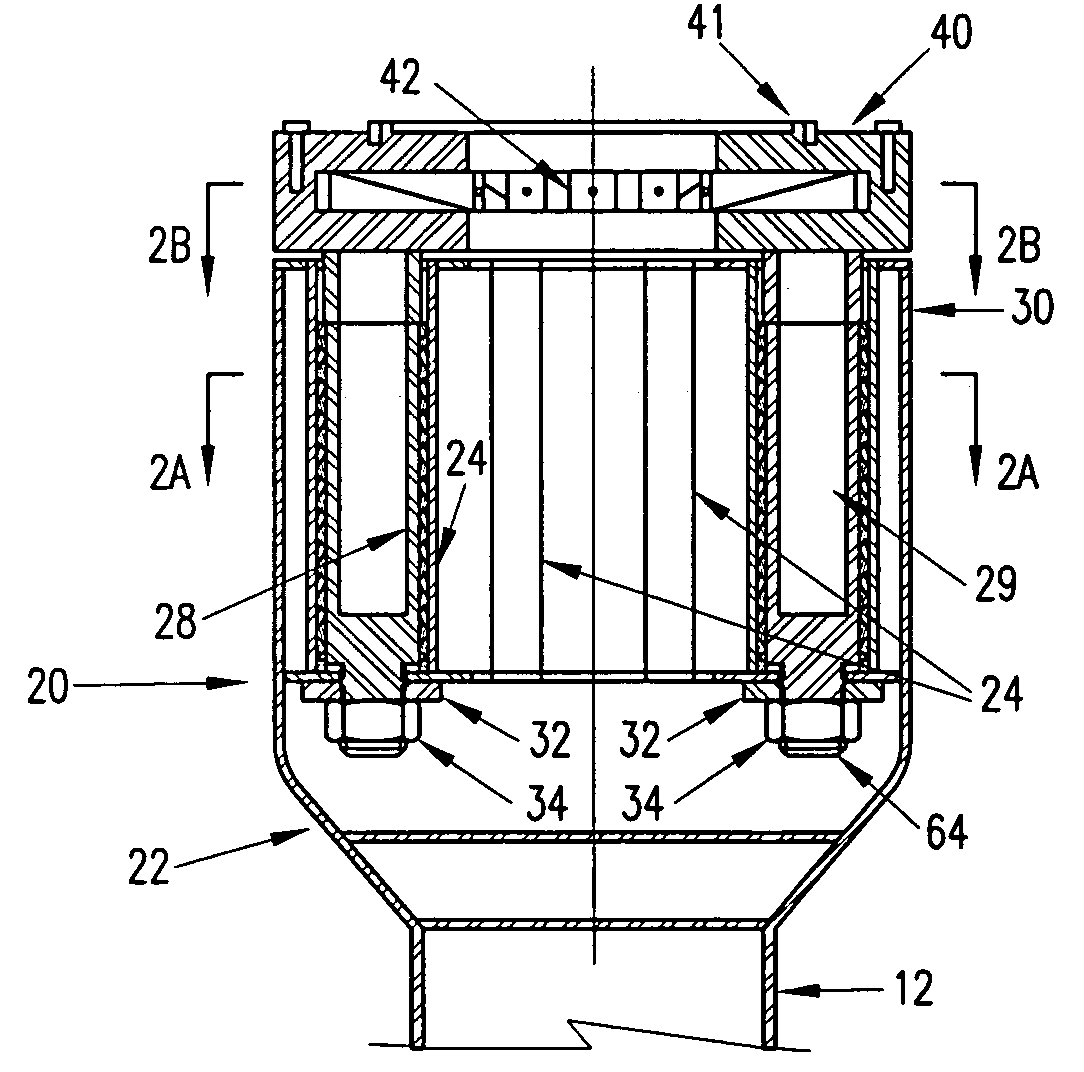

Image

Examples

Embodiment Construction

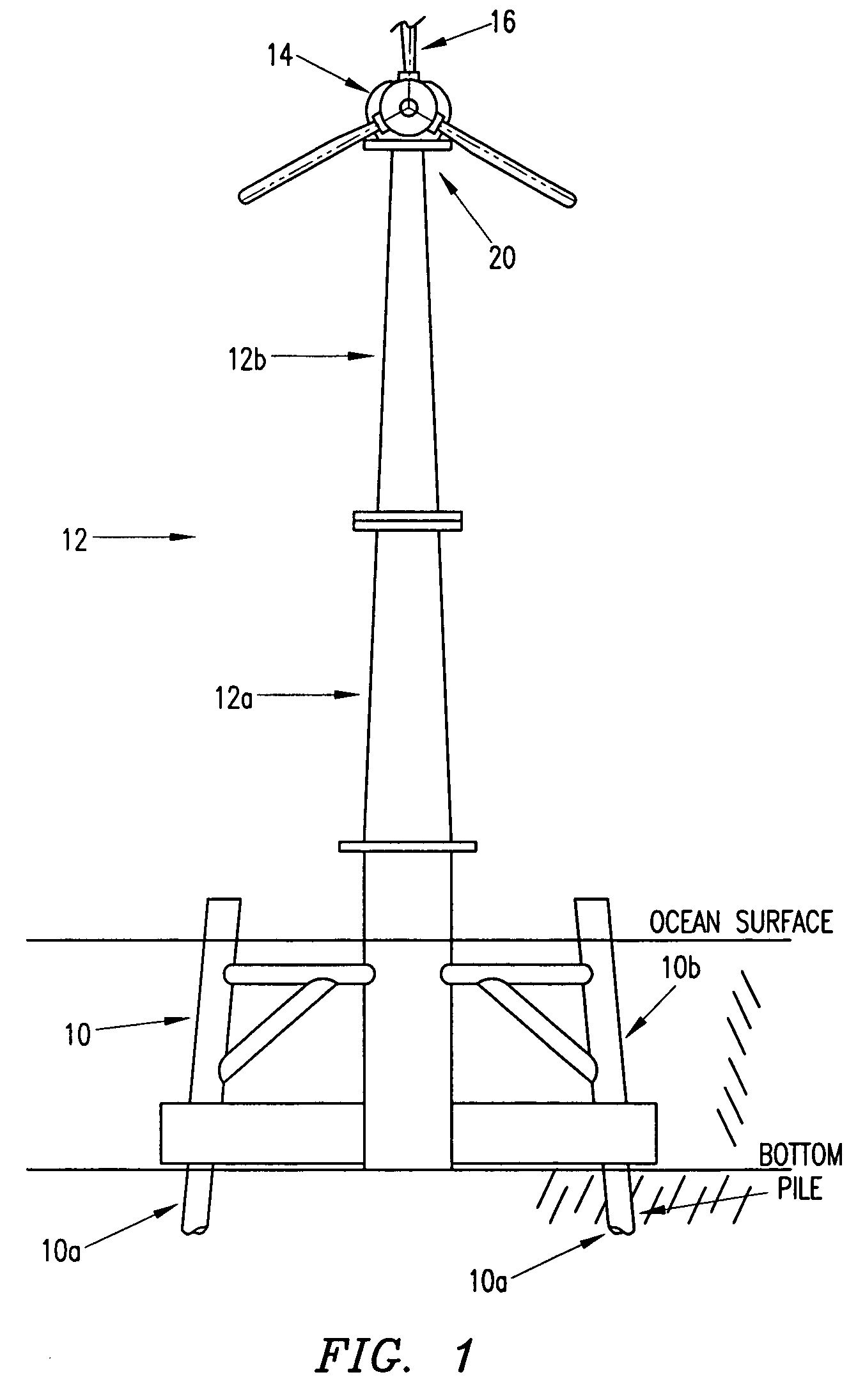

[0023]The installation costs must also be controlled to allow economic benefit to this operation. Therefore, in considering transportation, lifting, assembly, weather conditions, and other factors a lift boat unit appears to be the most economical method by which the installation of the windmill assembly can be accomplished. Lift boats have been used in offshore oil production for years and can operate in water depths of six feet through 200 feet and are also used to erect windmill structure. The lift boat has three or four legs for stability on which the structure is lifted out of the water to the height desired adjacent to the windmill structure for stability purposes. The lift boat would carry the parts the structure to the site and use rotating cranes of about 150-ton capacity to assemble the structure.

[0024]In order to facilitate the assembly of the tower assembly and nacelle generating pod, a work platform is required. A work platform is mounted to cantilever beams which can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com