Flume for a filter system including at least one filter having a filter bed that is periodically washed with liquid, gas or a combination thereof

a filter system and filter bed technology, applied in the direction of moving filter element filters, filtration separation, separation processes, etc., can solve the problems of high risk of mal-distribution of washing fluid through the filter bed, high risk of mal-distribution of washing fluid to the underdrain and ultimately the filter bed, etc., to reduce turbulence and disruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

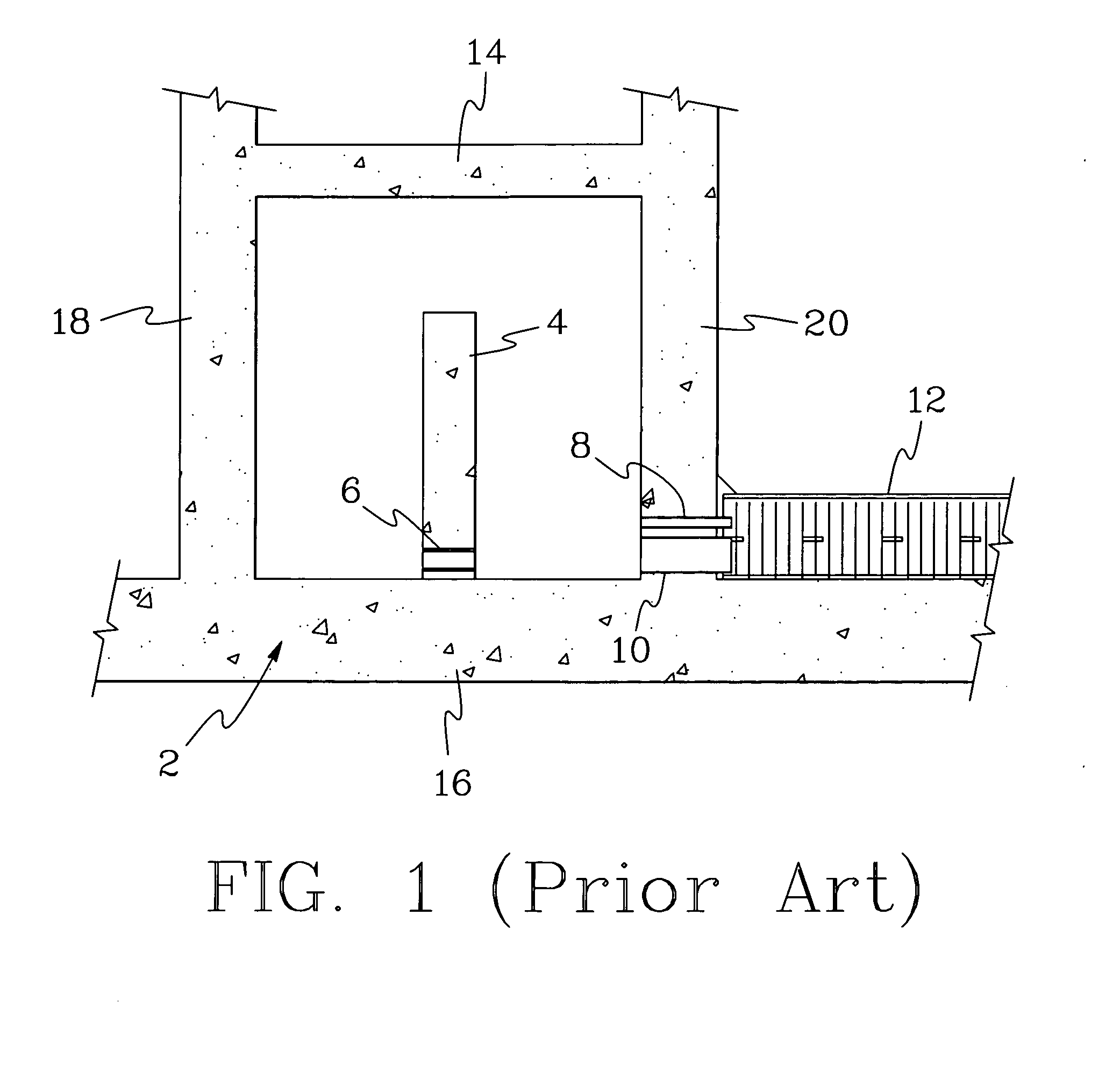

[0042]The preferred forms of the invention will now be described with reference to FIGS. 2-18. The appended claims are not limited to the preferred forms and no term and / or phrase used herein is to be given a meaning other than its ordinary meaning unless it is expressly stated otherwise. The term “orifice” as used herein and in the relevant industry means “an opening having a closed perimeter through which a fluid may discharge.”

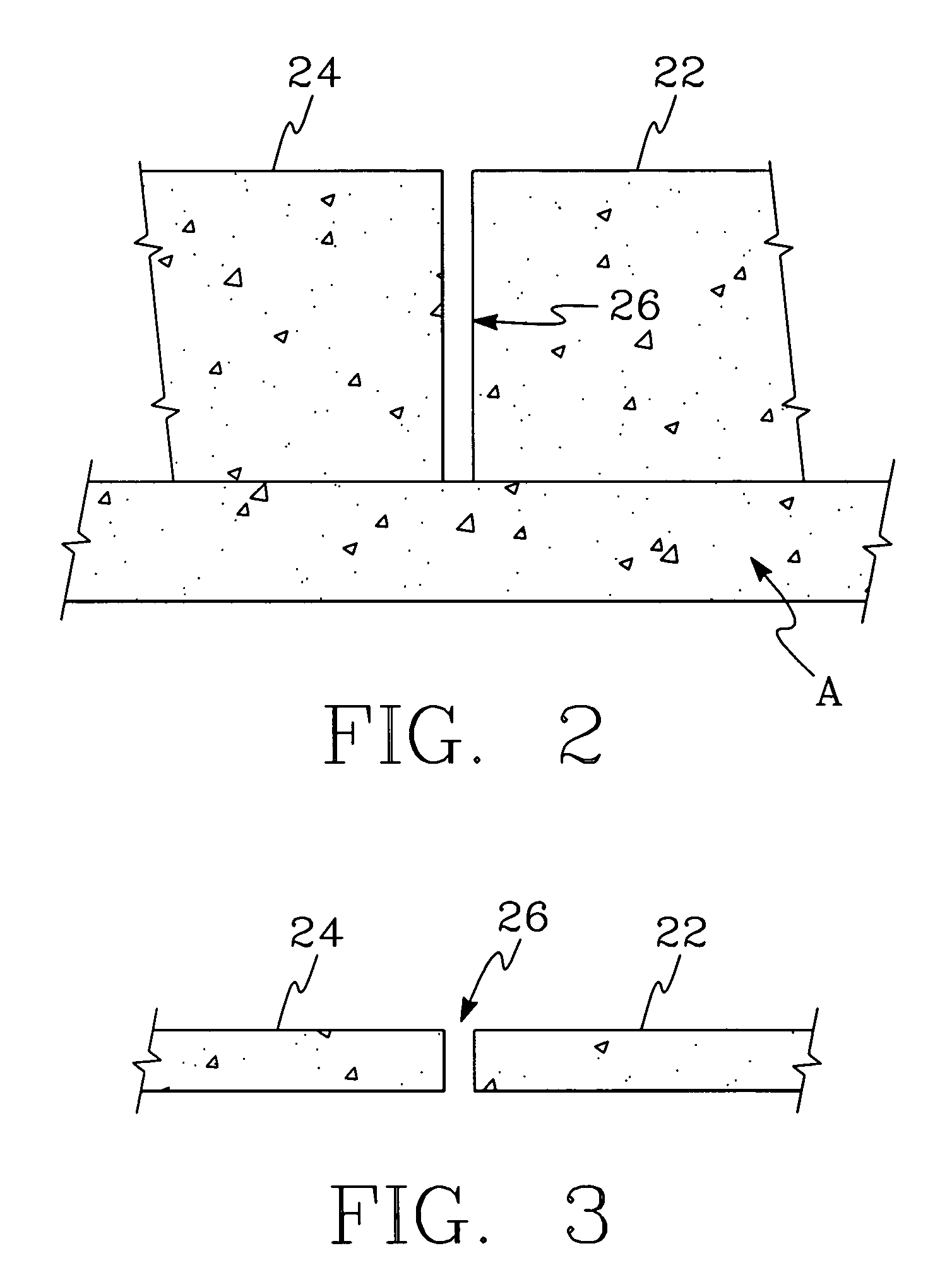

FIGS. 2 Through 18

[0043]Referring to FIG. 2, a fragmentary portion of a flume A formed in accordance with a preferred embodiment of the present invention is illustrated. Preferably, flume A is similar in exterior construction to flume 2 depicted in FIG. 1, i.e., the flume A preferably has an exterior performed by a top wall 14, a bottom wall 16, a left sidewall 18 and a right sidewall 20 as depicted in FIG. 1. Preferably, the bottom wall is at approximately the same elevation as the bottom of the filter housing as shown in FIG. 1. This arrangement is often ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com