Thin-film magnetic head

a thin-film magnetic head and magnetic head technology, applied in the field can solve problems such as fluctuation of thin-film magnetic heads, and achieve the effects of reducing cracks, improving coating ratio, and keeping performances from fluctuating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0085]The present invention will now be explained more specifically with reference to Examples 1-1 to 1-9 and Comparative Examples 1-1 and 1-2 and FIG. 11, but is not restricted to the following examples. FIG. 11 is a table showing embodied conditions and evaluation results of Examples 1-1 to 1-9 and Comparative Examples 1-1 and 1-2.

example 1-1

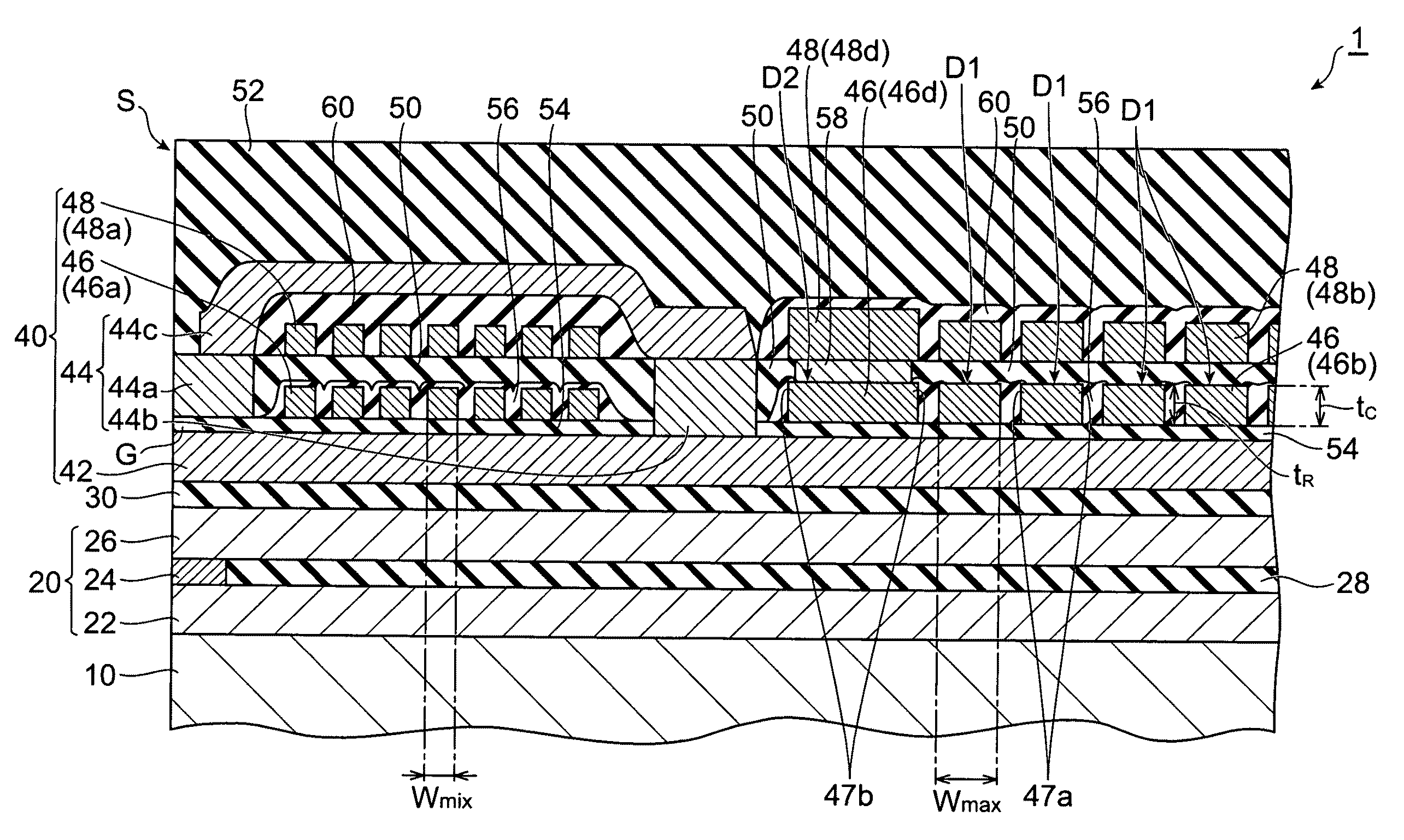

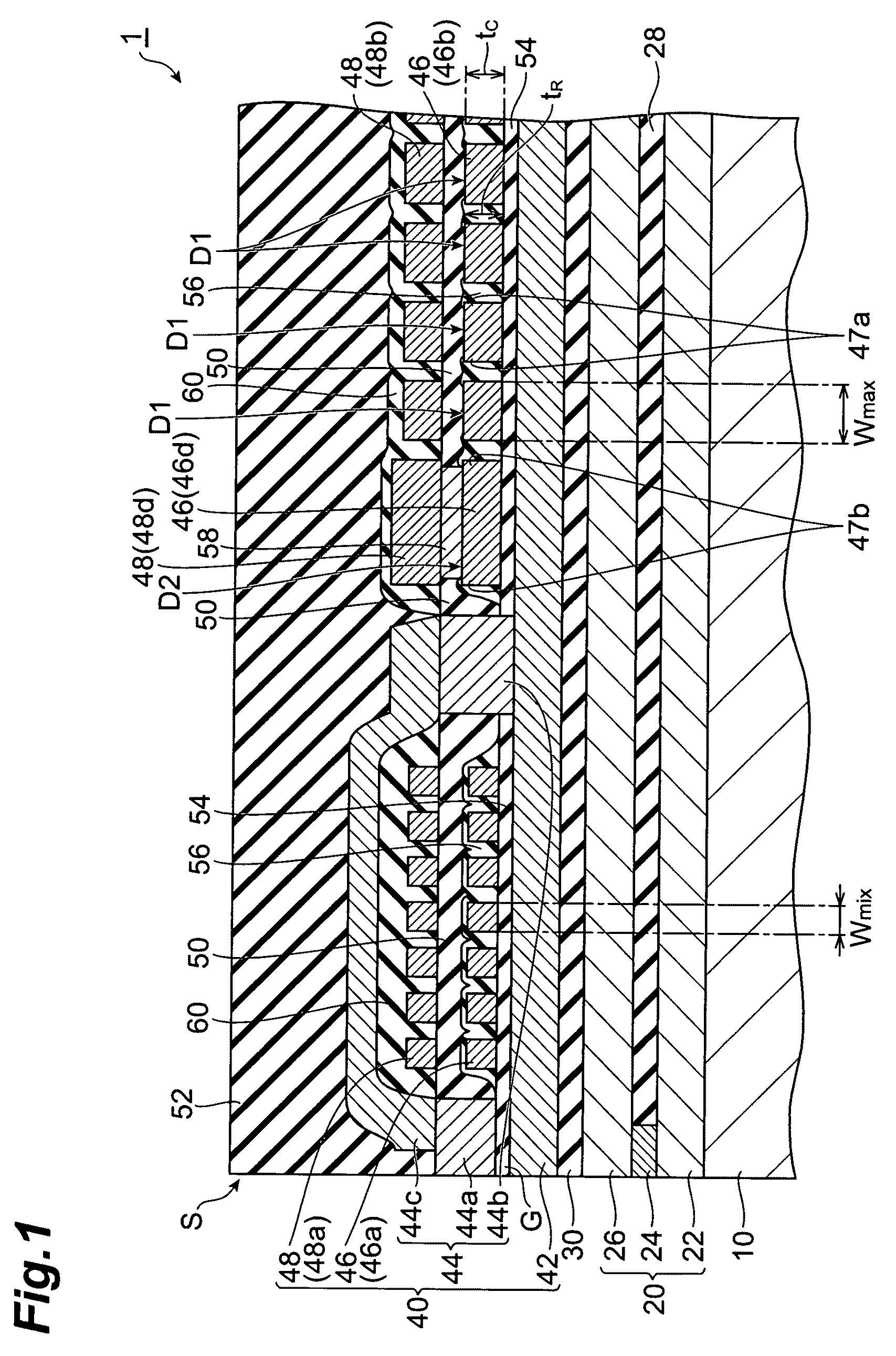

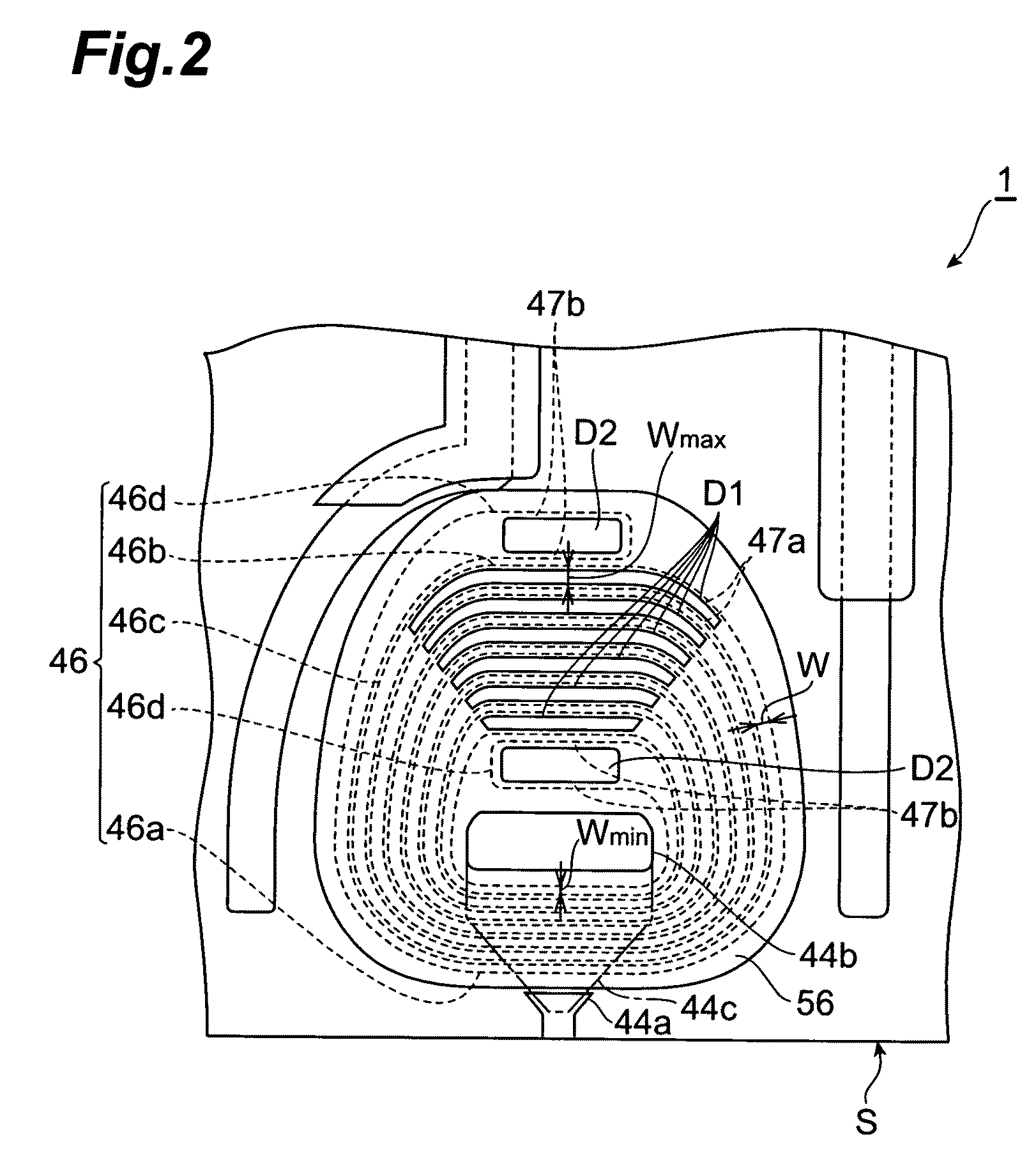

[0086]On a substrate made of Al2O3.TiC, Al2O3 was laminated as an undercoat layer, so as to form the support 10. Then, according to the above-mentioned method of manufacturing the thin-film magnetic head 1, the reading head part 20, the insulating layer 30, the recording head part 40, the resist films 56, 60, and the insulating layers 50, 52 were formed, so as to yield the thin-film magnetic head 1. In the thin-film magnetic head 1 of Example 1-1, the lead width Wmin of the minimum width part 46a as seen from the upper part in the laminating direction was set to 1.9 μm, while the lead width Wmax of the maximum width part 46b as seen from the upper part in the laminating direction was set to 5.0 μm. Also, in the thin-film magnetic head 1 of Example 1-1, the thickness tC of the maximum width part 46b in the laminating direction was set to 2.0 μm, while the thickness tR of the resist film 56 in the laminating direction was set to 2.5 μm, so that the ratio tC / tR of the thickness tC of t...

examples 1-2 to 1-9

[0089]The thin-film magnetic heads 1 of Examples 1-2 to 1-9 were obtained as in Example 1-1 except that X was set to 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, and 0.9, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width Wmax | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com