Modular hip joint implant

a hip joint and module technology, applied in the field of modular hip joint implants, can solve the problems of still being bulky or cumbersome to obtain modular components, and achieve the effect of improving the stability and stability of the hip join

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The following description of various embodiments is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses. For example, although the invention is illustrated for a hip implant, the invention can be used with any type of prosthesis for a bone such as, for example, a proximal or distal femur, a proximal or distal tibia, a pro

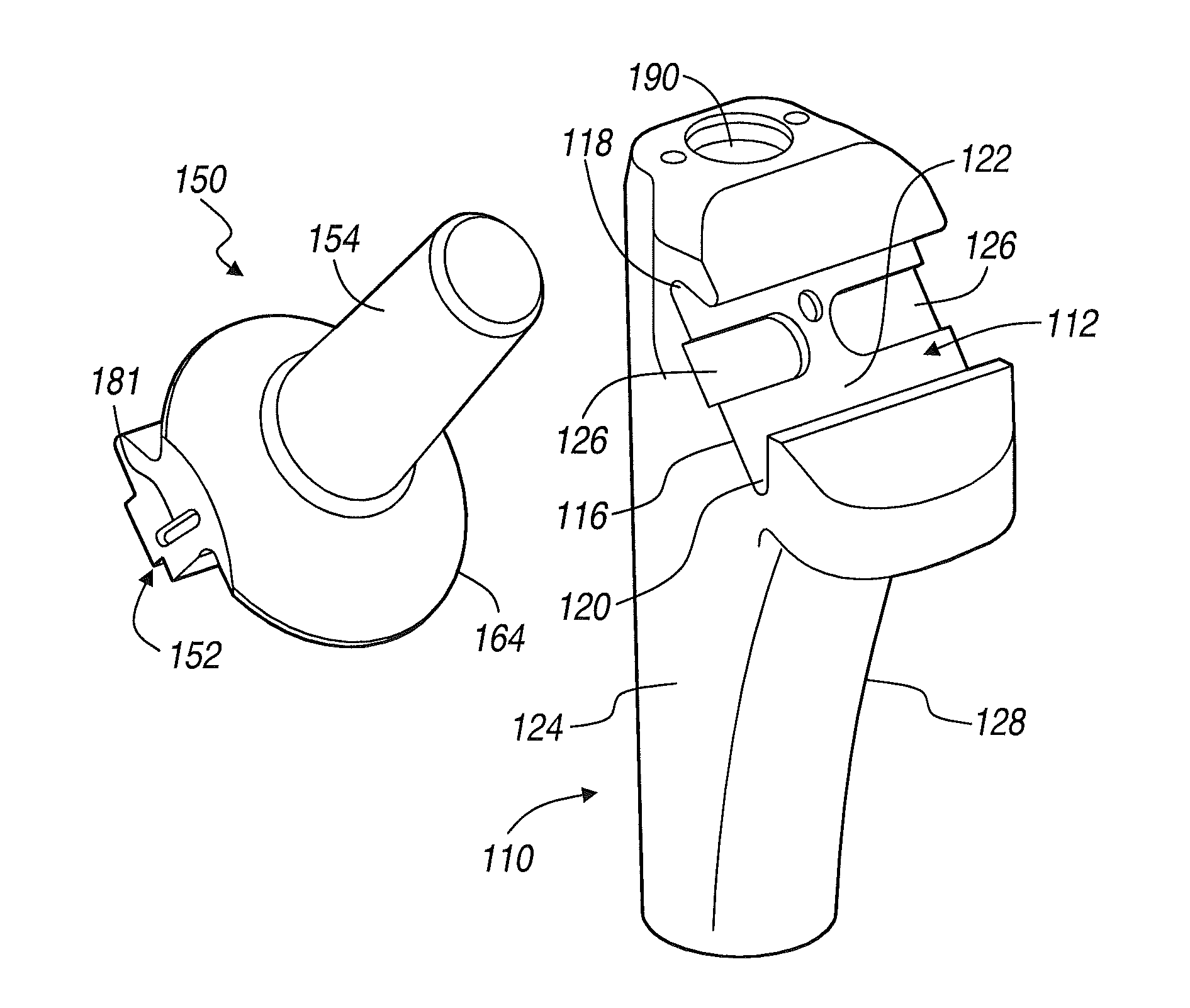

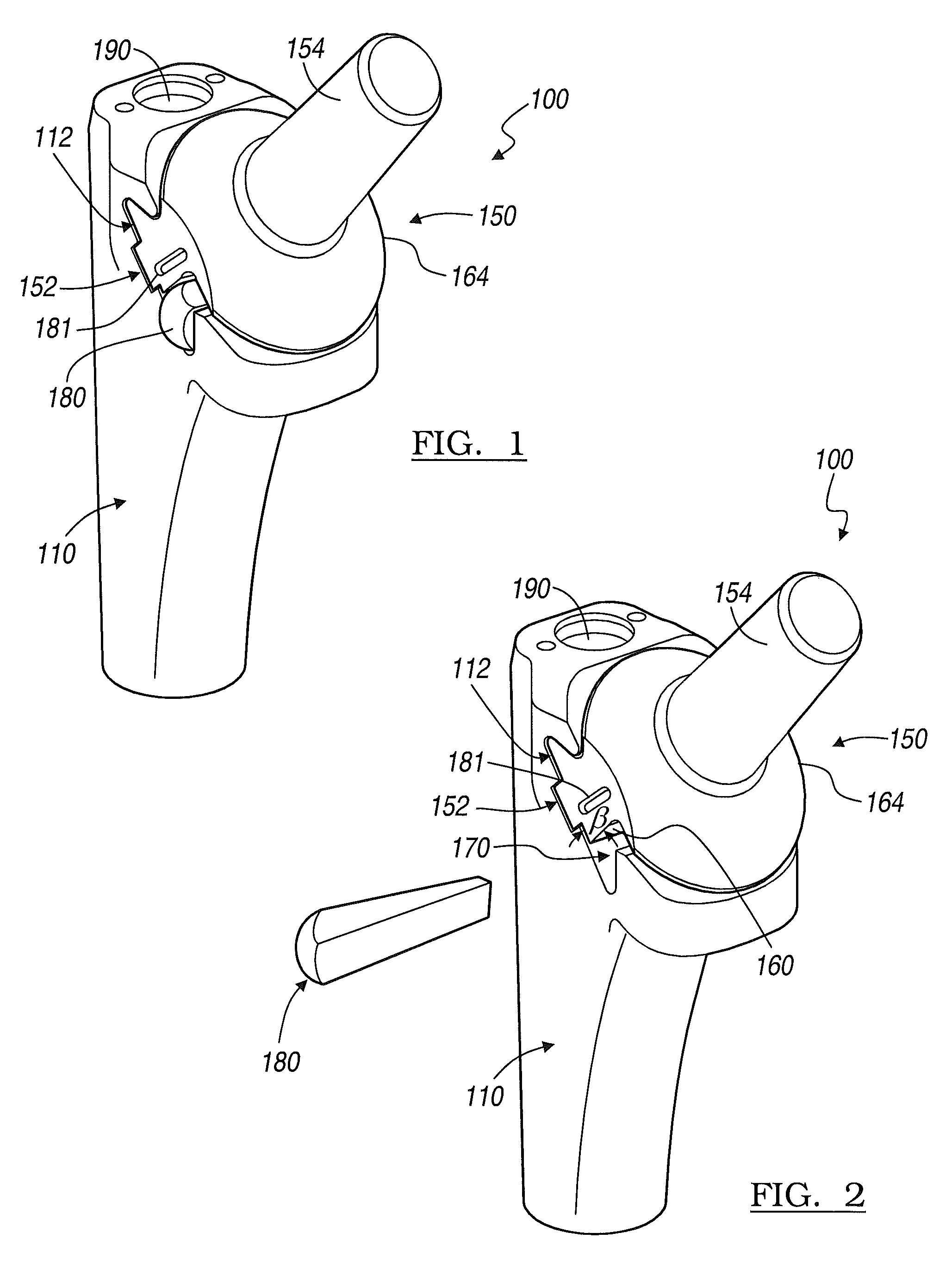

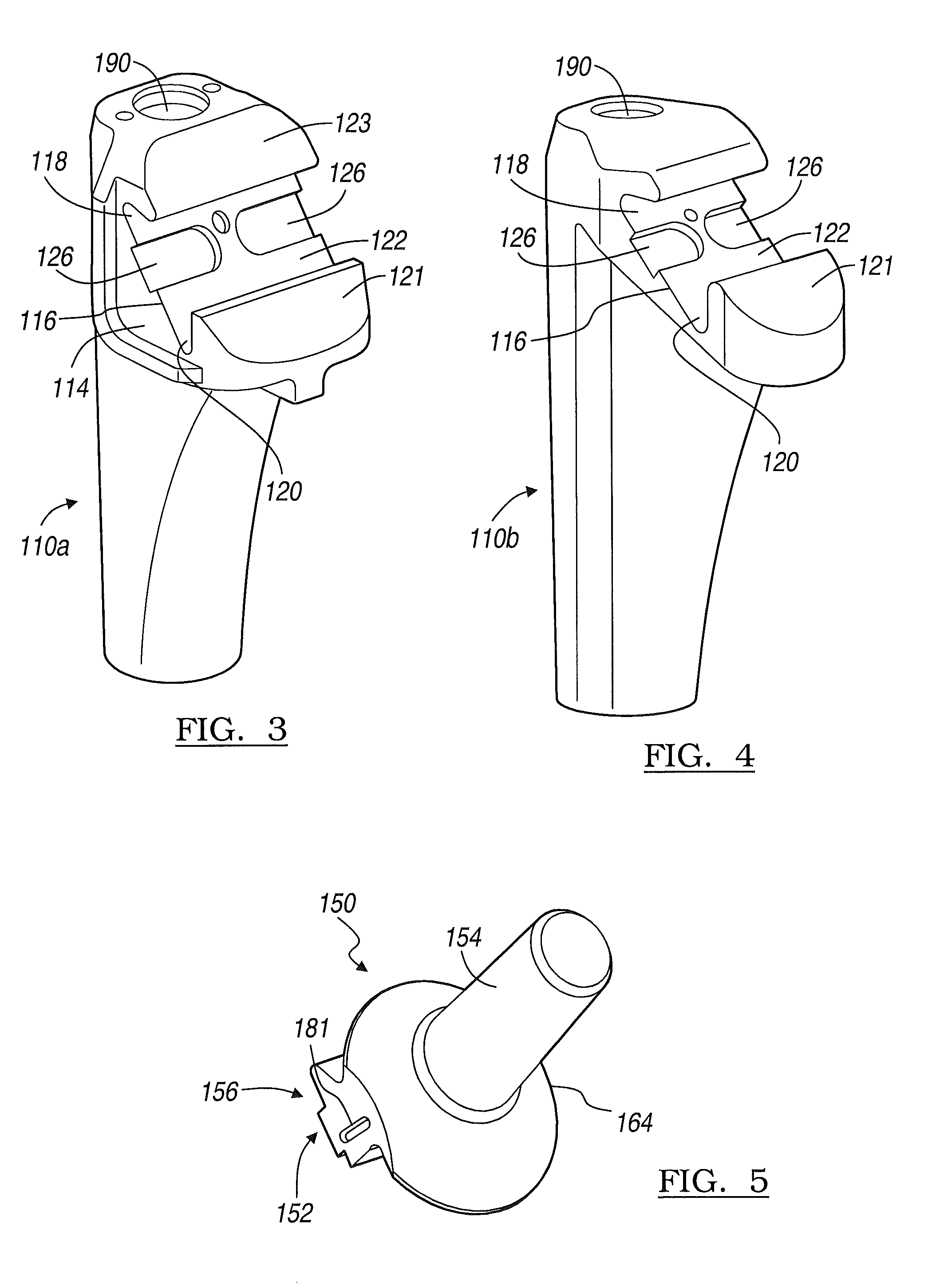

[0032]FIGS. 1, 13 and 14 illustrate respectively an exemplary of a modular hip joint implant 100 and an exemplary modular hip replacement system 300. The implant 100 includes a femoral stem 110, a neck component 150, and a key 180. The femoral stem 110 and the neck component 150 have opposing interlocking proximal stem and distal neck surfaces 112, 152, which allow for relative sliding therebetween, as best seen in FIGS. 8 and 9. When interlocked, the femoral stem 110 and neck component 150 define a keyway 170. The key 180 can be wedged into the keyway 170 to lock the components of the modular hip joint implant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com