Cover for temperature sensor

a temperature sensor and cover technology, applied in the field of refrigeration systems, can solve the problems of inconvenient reapplication, difficult removal, inconsistent reapplication results,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

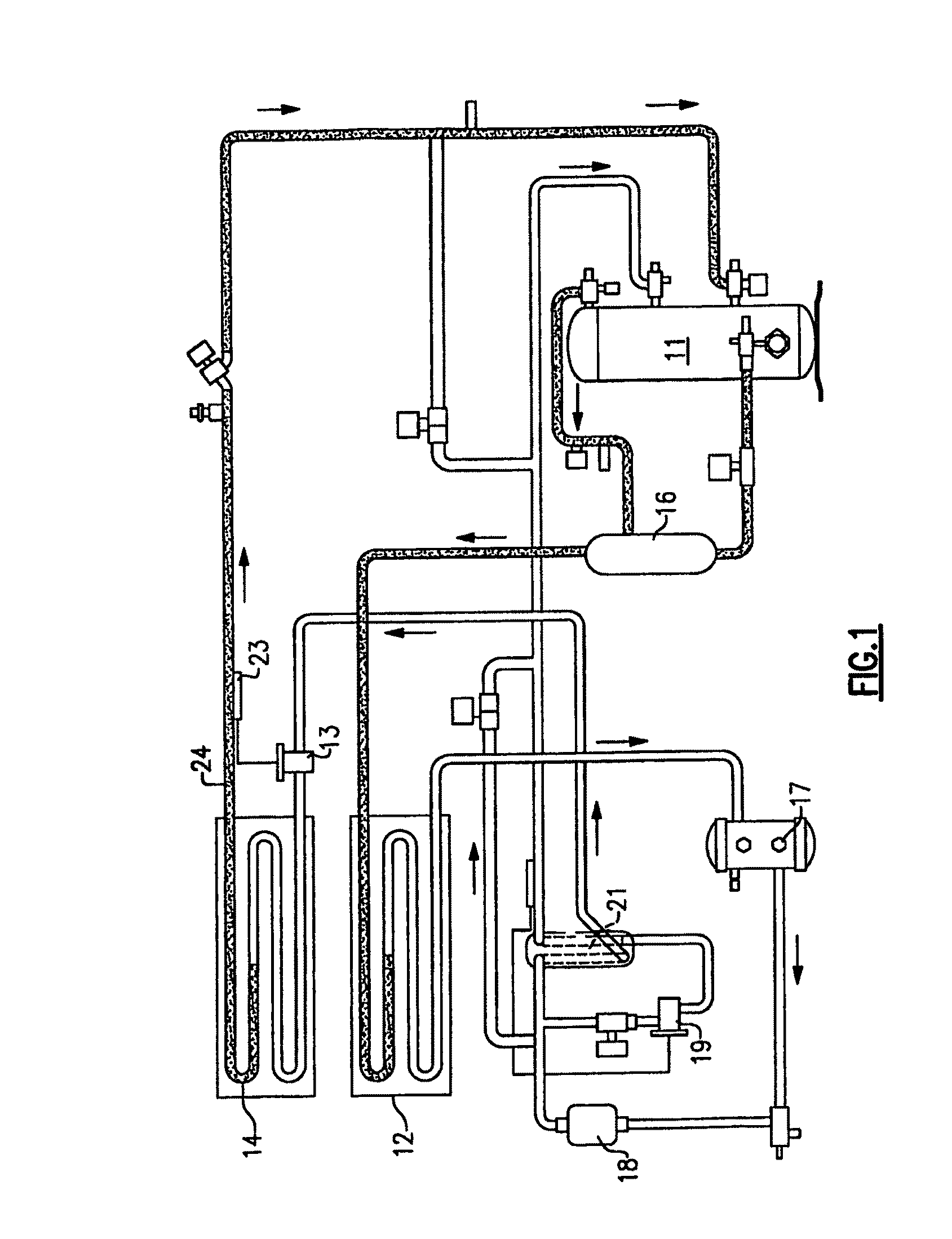

[0015]FIG. 1 is a schematic illustration of a transport refrigeration system of the type to which the present invention is applicable. Connected in typical serial flow relationship are a compressor 11, a condenser 12, an expansion device or thermal expansion valve (TXV) 13 and an evaporator coil 14. The refrigerant is caused by the compressor 11 to flow through the system in a well known manner.

[0016]Other components that are normally included in the system are an oil separator 16, a receiver 17, a filter dryer 18, an economizer TXV 19, and an economizer heat exchanger 21. The oil separator 16 functions to separate the oil from the compressed refrigerant so it can return to the compressor 11. The receiver stores refrigerant for use in low temperature operation. The filter dryer 18 removes moisture and impurities from the refrigerant. The economizer is used to provide frozen range and pull down capacity of the unit by subcooling the liquid refrigerant entering the evaporator TXV 13 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com