Cathode discharge apparatus

a discharge apparatus and cathode technology, applied in the direction of electrical devices, gas discharge lamp details, electric discharge tubes, etc., can solve the problems of difficult to raise the conversion efficiency of solar cells, limited utilization rate of solar energy, and urgent problem of looking for substitute energies, etc., to achieve high ionization and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0035

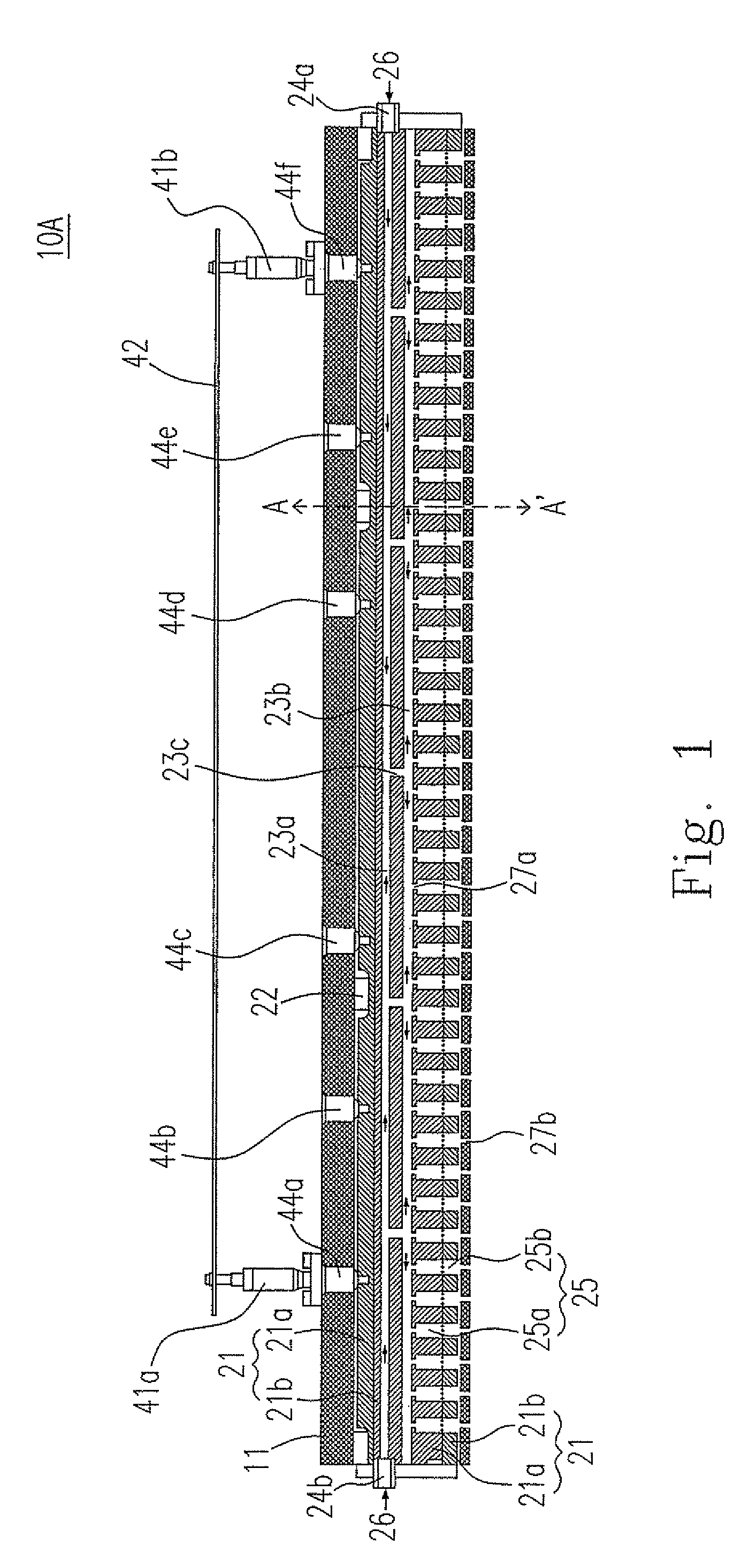

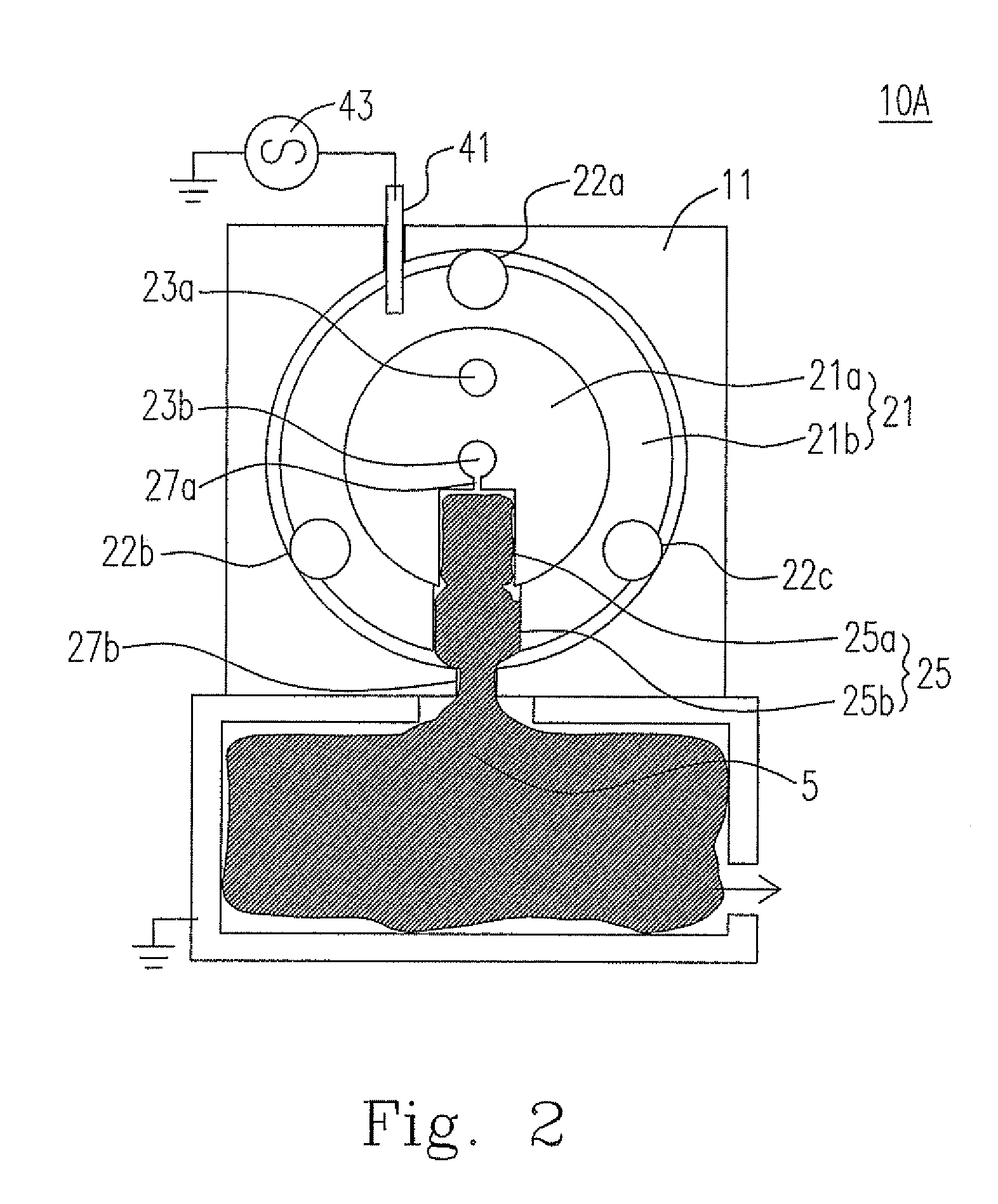

[0036]FIG. 1 is the schematic diagram showing the cross section of the cathode discharge apparatus from the side view according to the first embodiment of the present invention. FIG. 2 is the schematic diagram showing the cross section of the cathode discharge apparatus in FIG. 1 along the A-A line according to the first embodiment of the present invention. Please refer to FIG. 2. The cathode discharge apparatus 10A includes the anode 11, the cathode 21 and the cathode chamber 25. The cathode 21 is located inside the anode 11. The insulators 22a, 22b and 22c separate the cathode 21 and anode 11.

[0037]The cathode 21 includes plural cathode chambers 25, and can be divided into the first portion 21a and the second portion 21b, which may be two pieces contacted with each other for facilitating the machining process, or may be made in one piece. Each of the cathode chambers 25 can be divided into the first portion 25a and the second portion 25b, where the first portion 25a of the ca...

second embodiment

[0047

[0048]The cathode discharge apparatus of the present embodiment is almost identical to that in the first embodiment. The only difference between the present embodiment and the first embodiment is: in the first embodiment, the cathode chambers 25 are designed to be parallel to one another and are oriented vertically downward, so the plasma is injected vertically downward via the chamber outlets 27b; while in the present embodiment, the cathode chambers 25 are designed to tilt at an angle relative to the vertical direction. The FIG. 3 is the schematic diagram showing the cross section of the cathode discharge apparatus according to the second embodiment of the present invention. The difference between the present embodiment and the first embodiment can be told by referring to FIGS. 2 and 3 simultaneously. The cathode chambers of the present embodiment tilts at a small angle, e.g. 5-30 degree, relative to the vertical direction, and can be aligned in a way, where the odd-numbered ...

third embodiment

[0049

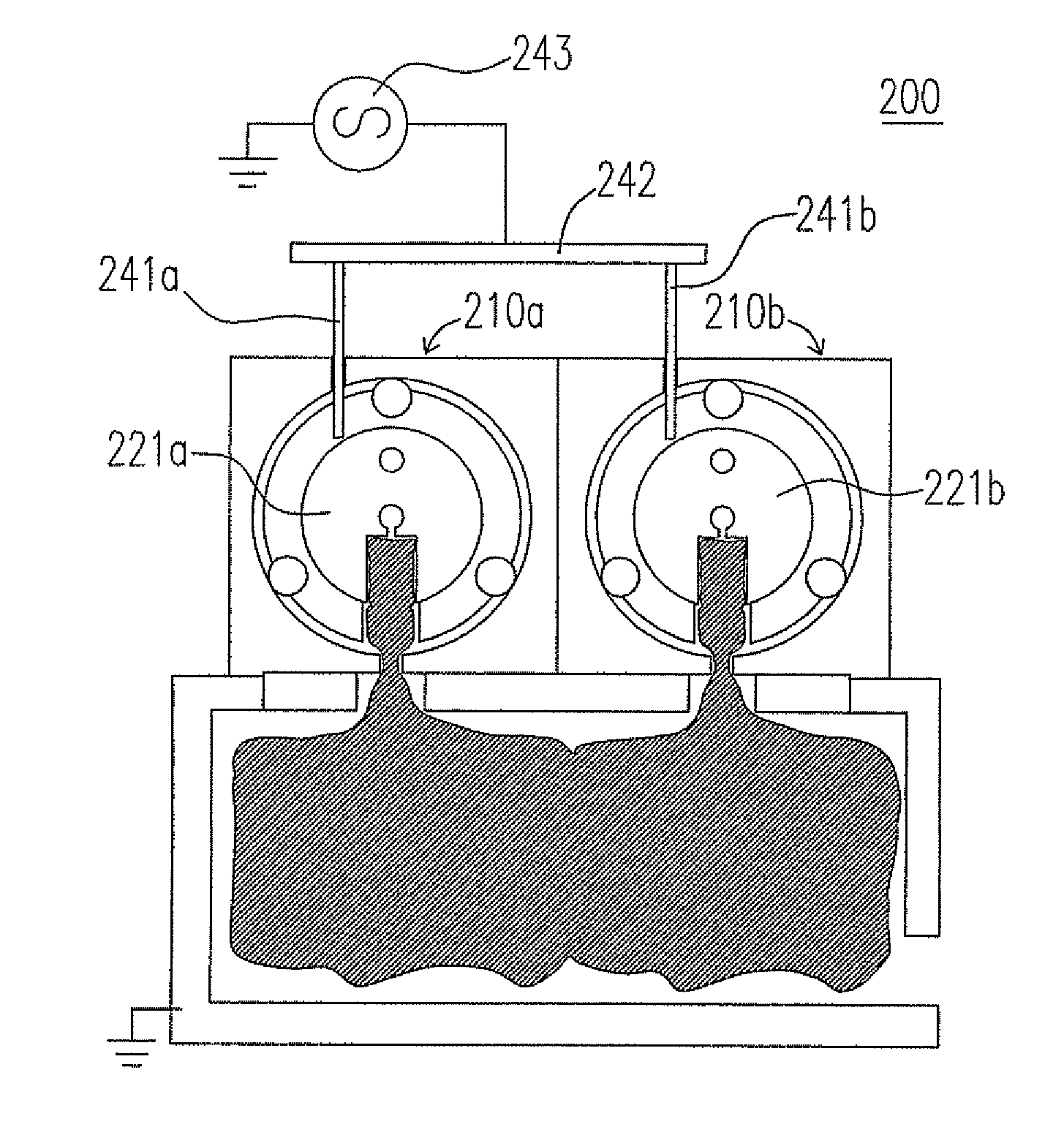

[0050]Please refer to FIG. 4, which is the schematic diagram showing the cross section of the cathode discharge apparatus according to the third embodiment of the present invention. In this embodiment, the cathode discharge apparatus 100 includes an anode 110 and two cathodes 121a and 121b, where the structure of each cathode is almost the same as that of the first embodiment. That is to say, two parallel aligned tubular cathodes 121a and 121b are enclosed inside the anode 110, and share the single anode 110. The two cathodes 121a and 121b have the electrical feedthroughs 141a and 141b, respectively. The cathode discharge apparatus 100 can contain the electrode connecting element 142 and the power supply 143, both of which are electrically connected, and the power supply 143 can provide power to the cathodes 121a and 121b through the electrode connecting element 142 and the electrical feedthroughs 141a and 141b.

[0051]FIG. 5 is the schematic diagram showing the 3-dimensinal vie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com