Organoruthenium complex, and method for production of ruthenium thin film using the ruthenium complex

a technology of ruthenium complex and ruthenium complex, which is applied in the field of organoruthenium complex and method for producing ruthenium thin film using ruthenium complex, can solve the problems of reducing the specific resistance value and the specific resistance value, and achieves excellent stability against moisture, air and heat. , the effect of low melting poin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

of the Present Invention

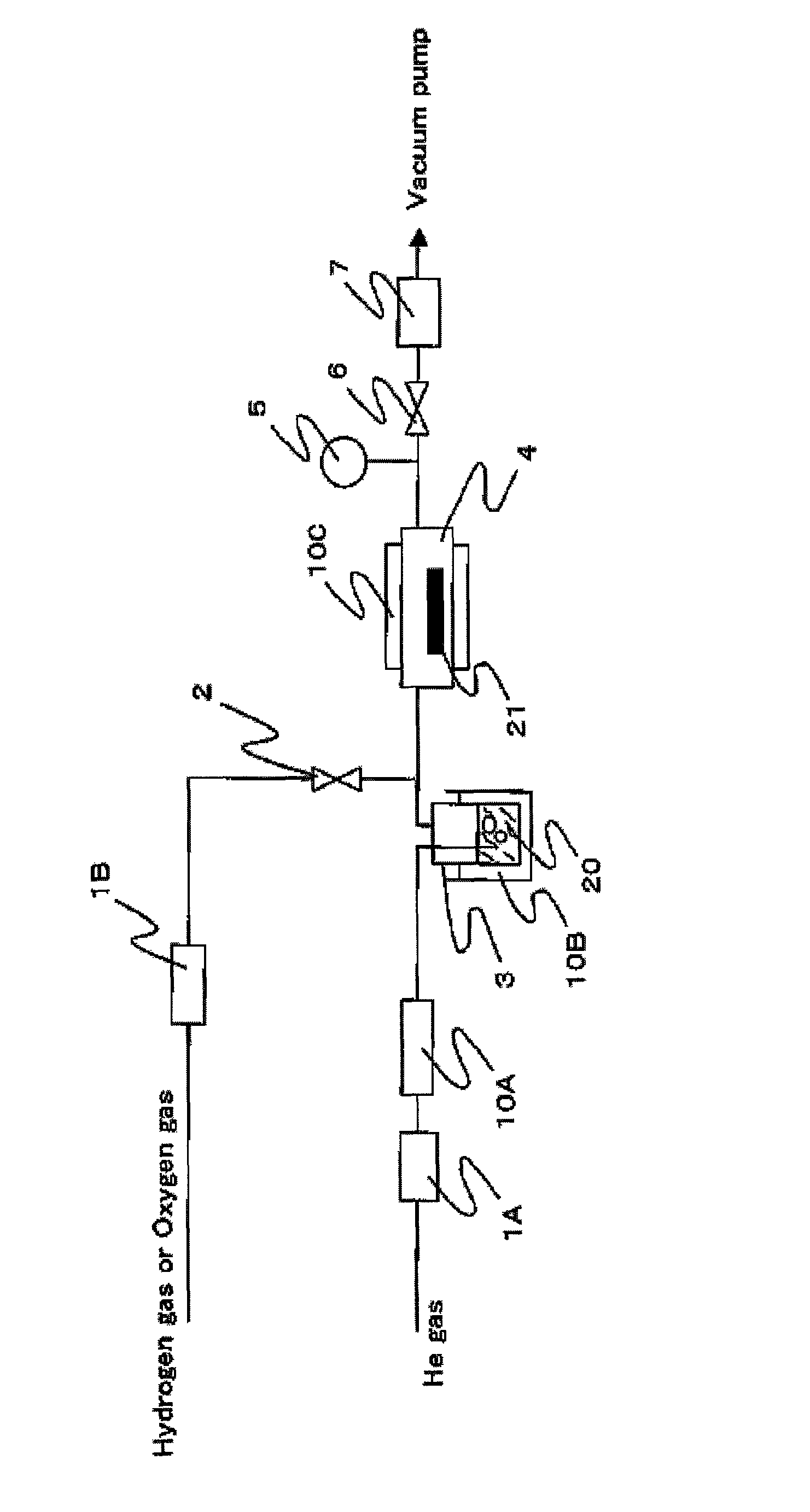

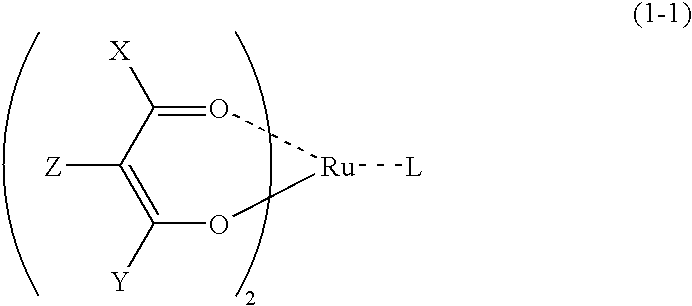

[0080]There will be described the first embodiment of the present invention, i.e. an organoruthenium complex represented by the above general formula (1-1) which comprises a β-diketonato having an alkoxyalkylmethyl group and an unsaturated hydrocarbon compound having at least two double bonds as a ligand, and a method for producing a ruthenium-containing thin film using the ruthenium complex. The organoruthenium complex has a low melting point, excellent stability against moisture, air and heat, and is suitable for the film formation by a CVD method. Furthermore, a metallic ruthenium-containing thin film which does not comprise a ruthenium oxide can be produced by a chemical vapor deposition method using the organoruthenium complex as a ruthenium source.

[0081]The organoruthenium complex of the present invention comprises a β-diketonato having an alkoxyalkylmethyl group and an unsaturated hydrocarbon compound having at least two double bonds as a ligand, and i...

second embodiment

of the Present Invention

[0088]There will be described the second embodiment of the present invention, i.e. bis(acetylacetonato)(1,5-hexadiene)ruthenium represented by the above formula (2-1), and a method for producing a ruthenium-containing thin film using the ruthenium complex. A metallic ruthenium-containing thin film which does not comprise a ruthenium oxide can be produced by a chemical vapor deposition method using the ruthenium complex as a ruthenium source.

[0089]Bis(acetylacetonato)(1,5-hexadiene)ruthenium may be prepared by reference to the known method for preparing a β-diketonato ruthenium complex having a diene compound as a ligand. For example, bis(acetylacetonato)(1,5-hexadiene)ruthenium may be prepared by reacting a ruthenium compound such as ruthenium chloride with 1,5-hexadiene in an organic solvent, and then adding acetylacetone thereto and reacting them.

[0090]In the CVD method of the present invention, it is necessary to vaporize bis(acetylacetonato)(1,5-hexadiene...

third embodiment

of the Present Invention

[0093]There will be described the third embodiment of the present invention, i.e. bis(acetylacetonato)(1,3-pentadiene)ruthenium represented by the above formula (3-1), and a method for producing a ruthenium-containing thin film using the ruthenium complex. A metallic ruthenium-containing thin film which does not comprise a ruthenium oxide can be produced by a chemical vapor deposition method using the ruthenium complex as a ruthenium source.

[0094]Bis(acetylacetonato)(1,3-pentadiene)ruthenium may be prepared by reference to the known method for preparing a β-diketonato ruthenium complex having a diene compound as a ligand. For example, bis(acetylacetonato)(1,3-pentadiene)ruthenium may be prepared by reacting a ruthenium compound such as ruthenium chloride with 1,3-pentadiene in an organic solvent, and then adding acetylacetone thereto and reacting them.

[0095]In the CVD method of the present invention, it is necessary to vaporize bis(acetylacetonato)(1,3-pentad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com