J-curve for a femoral prosthesis component

a femoral prosthesis and component technology, applied in the field of joint replacement surgery, can solve the problems of reducing the range of motion, reducing the stability of the knee prosthesis, and reducing the full range of motion, and achieve the effect of facilitating a close approximation to the motion and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

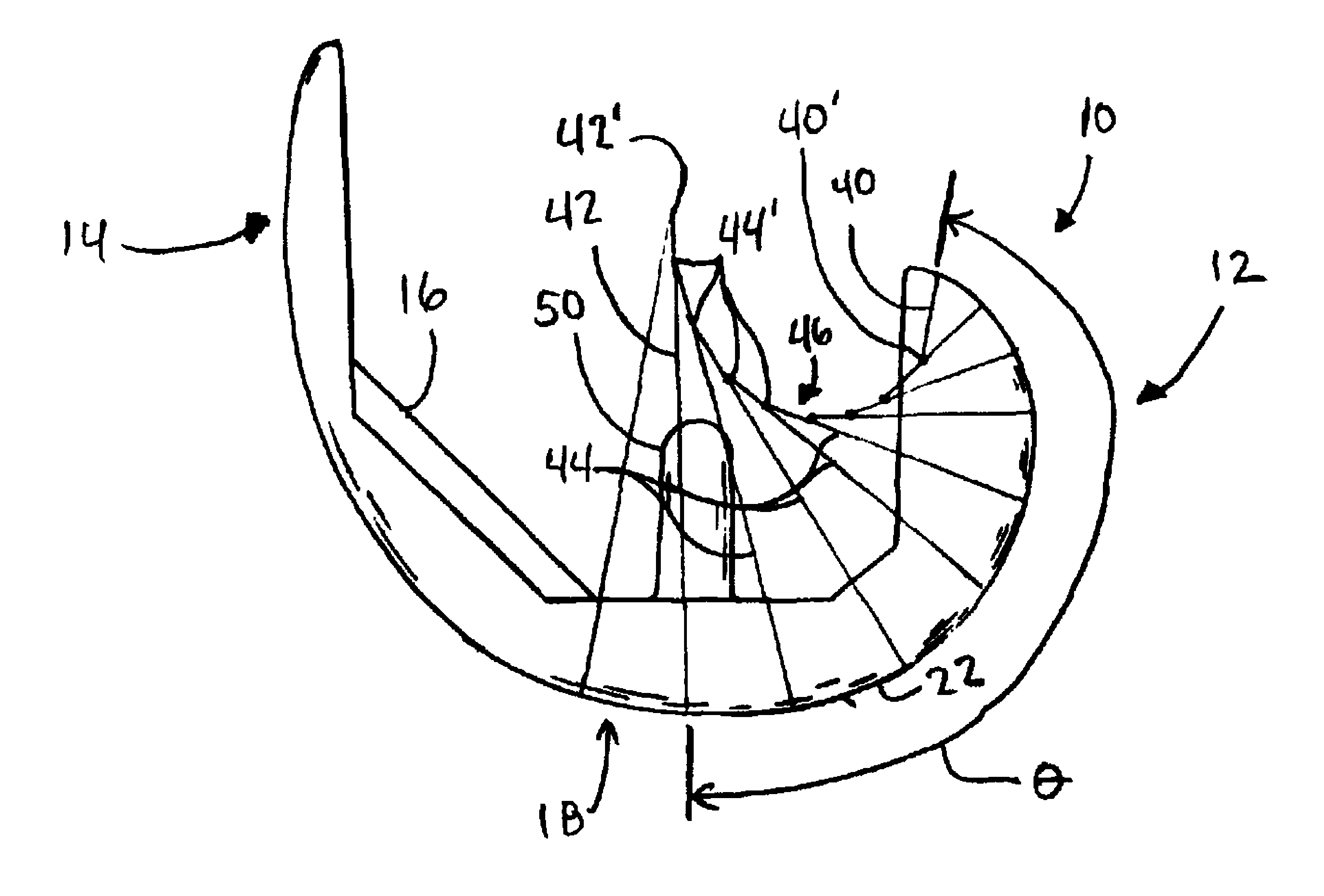

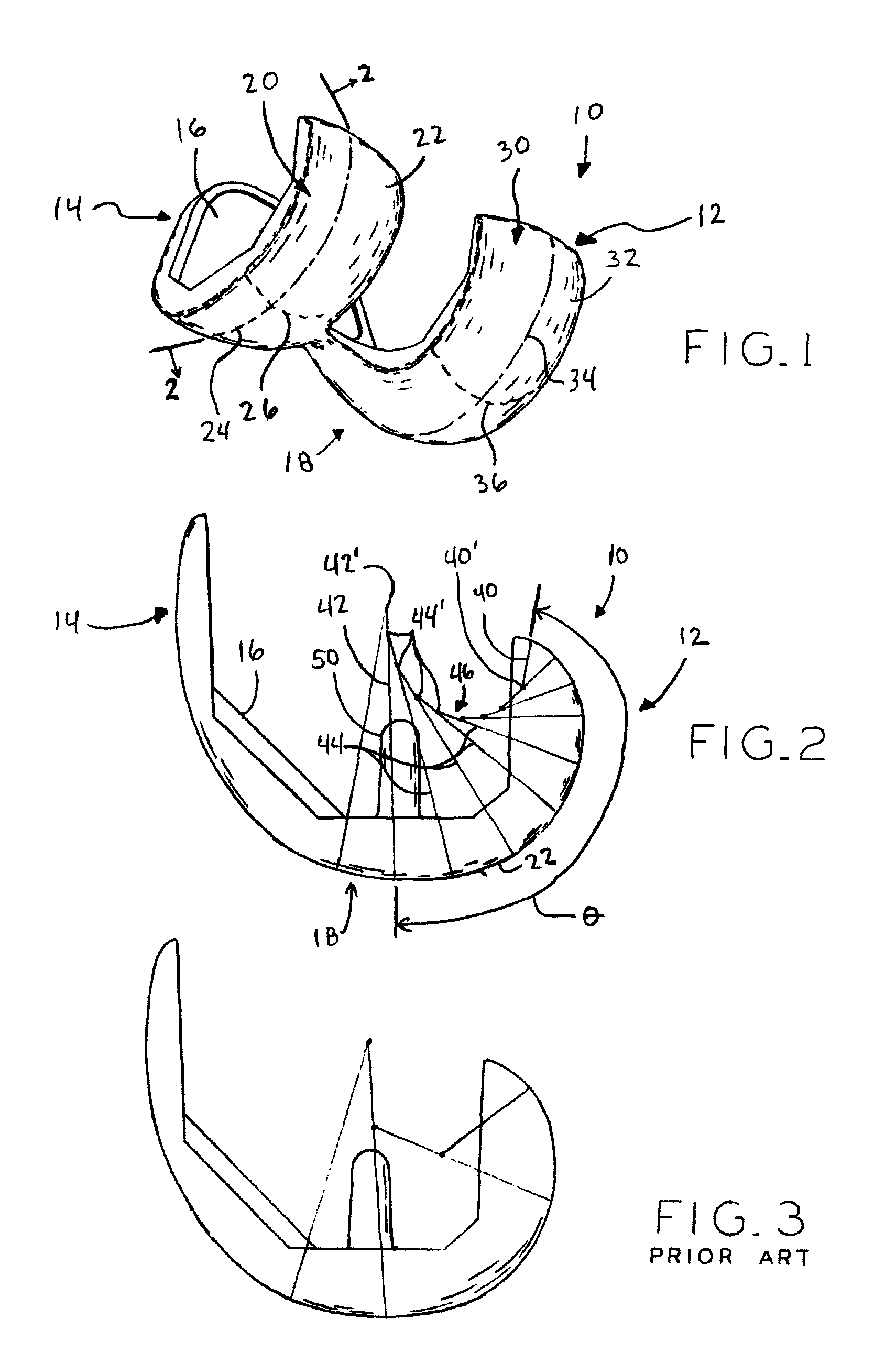

[0029]Referring to FIG. 1, femoral component 10 has posterior side 12 and anterior side 14 with a generally U-shaped profile extending therebetween. Proximal surface 16 is adapted to be secured to the distal end of a femur. The femur may or may not be resected prior to such attachment. A distal or articular surface 18 is disposed opposite the proximal surface 16 and is adapted to cooperate with a proximal surface of a tibial bearing member (not shown). Femoral component 10 may also be used in conjunction with natural tibial structures in a partial knee arthroplasty, or, alternatively, may be used in a total knee arthroplasty procedure as part of a total knee replacement (TKR). The TKR may include, for example, a tibial component with a distal end mounted to a proximal end of a tibia, femoral component 10 mounted to a distal end of a femur, and a tibial bearing member with a distal surface configured to engage the proximal end of the tibial component and a proximal surface sized and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com