Cover glass for photoelectric conversion devices and method for producing the same

a technology of photoelectric conversion device and cover glass, which is applied in the directions of semiconductor/solid-state device details, instruments, transportation and packaging, etc., can solve the problems of annoyance in the neighborhood in some cases, and achieve the effect of reducing light reflectance, reducing maximum reflection effect, and large roughness period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

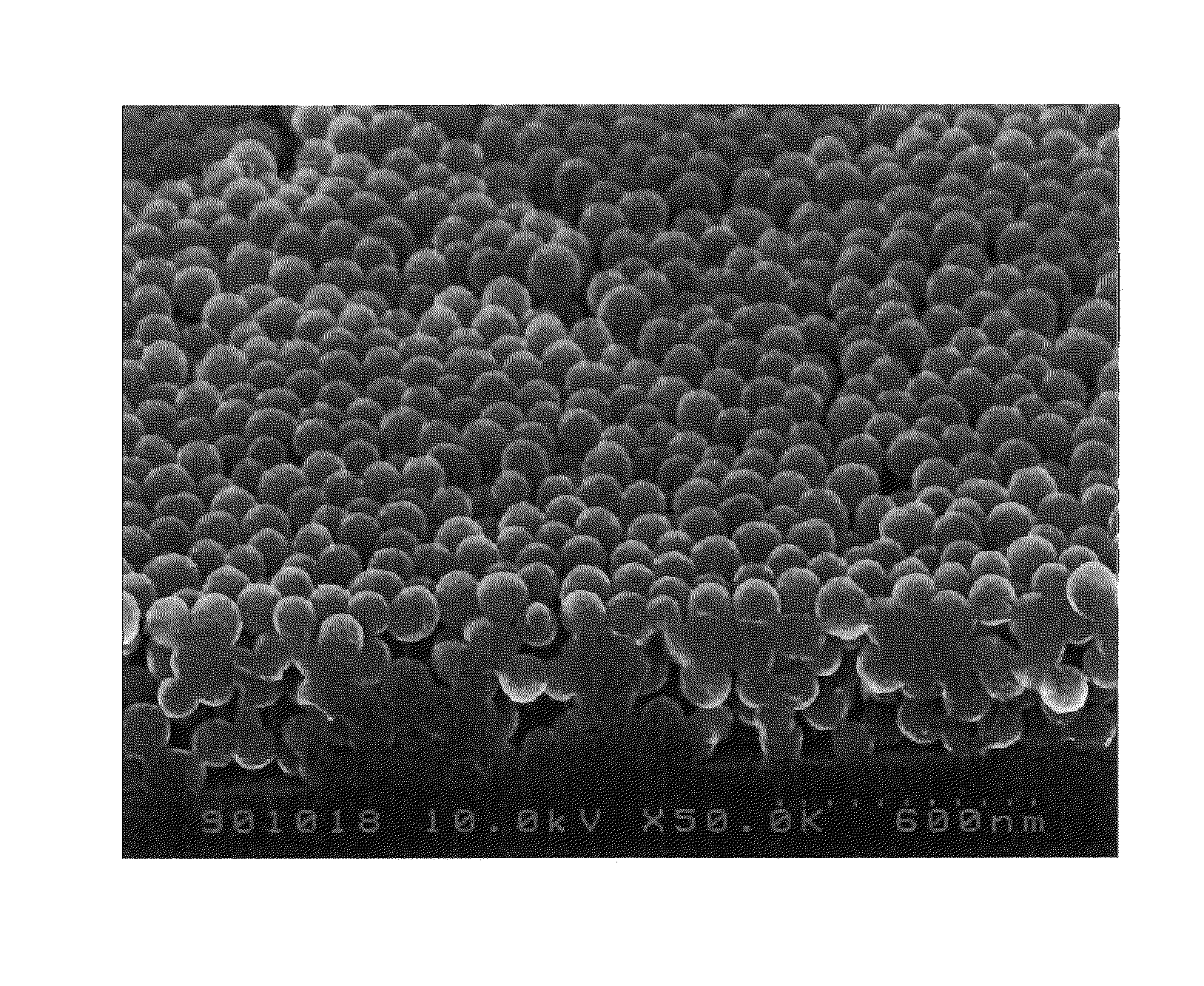

[0063]36.96 parts by weight of a silica fine particle dispersion (PL-7, manufactured by FUSO CHEMICAL CO., LTD, average particle size: 100 nm, solid content concentration: 23 wt %), 56.84 parts by weight of ethyl cellosolve, and 1.0 part by weight of 1N hydrochloric acid (hydrolysis catalyst) were mixed and stirred, to which 5.2 parts by weight of tetraethoxysilane was added under continuous stirring. Subsequently, it was stirred for 8 hours while being maintained at 40° C. Thus, an undiluted solution was obtained. In this undiluted solution, the solid content concentration was 10 wt % and the ratio of the fine particles and the binder (in terms of oxide) in the solid content was 85:15 on a weight basis. The above-mentioned silica fine particles were solid (in other words, non-hollow) fine particles.

[0064]13.0 parts by weight of the undiluted solution, 5.0 parts by weight of propylene glycol, 81.98 parts by weight of 2-propanol, and 0.02 part by weight of a silicone surfactant (Coat...

example 2

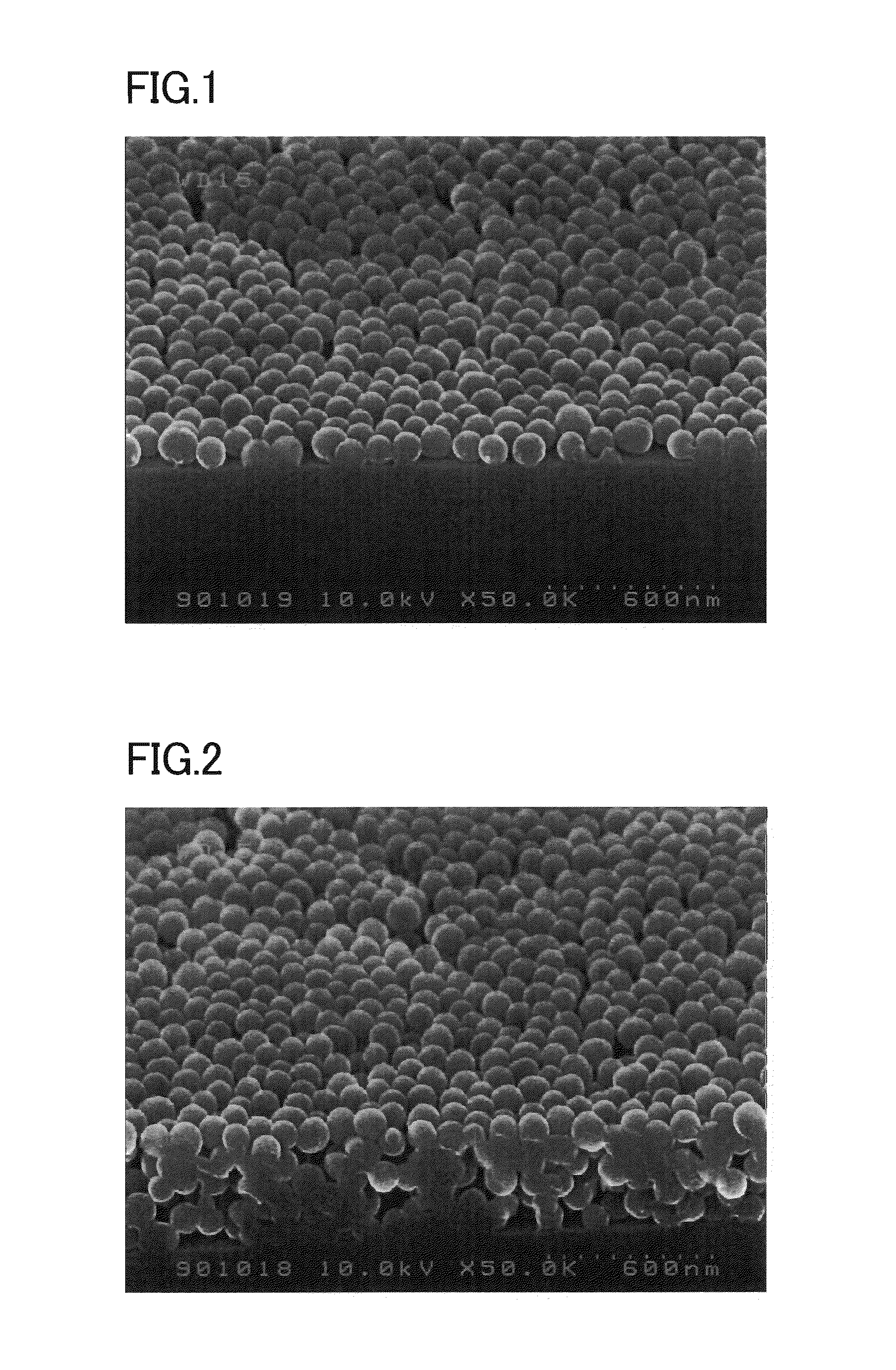

[0068]An undiluted solution was obtained in the same manner as in Example 1, except that the proportion of the respective raw materials employed for preparing the undiluted solution was changed as follows: 30.43 parts by weight of the silica fine particle dispersion, 58.17 parts by weight of ethyl cellosolve, 1.0 part by weight of concentrated hydrochloric acid, and 10.4 parts by weight of tetraethoxysilane. In this undiluted solution, the solid content concentration was 10 wt %, and the ratio of the fine particles and the binder (in terms of oxide) in the solid content was 70:30 on a weight basis.

[0069]Meanwhile, a coating solution was obtained in the same manner as in Example 1, except that the proportion of the respective raw materials employed for preparing the coating solution was changed as follows: 17.0 parts by weight of the undiluted solution, 5.0 parts by weight of propylene glycol, 77.95 parts by weight of 2-propanol, and 0.05 part by weight of a silicone surfactant. Note...

examples 3 to 8

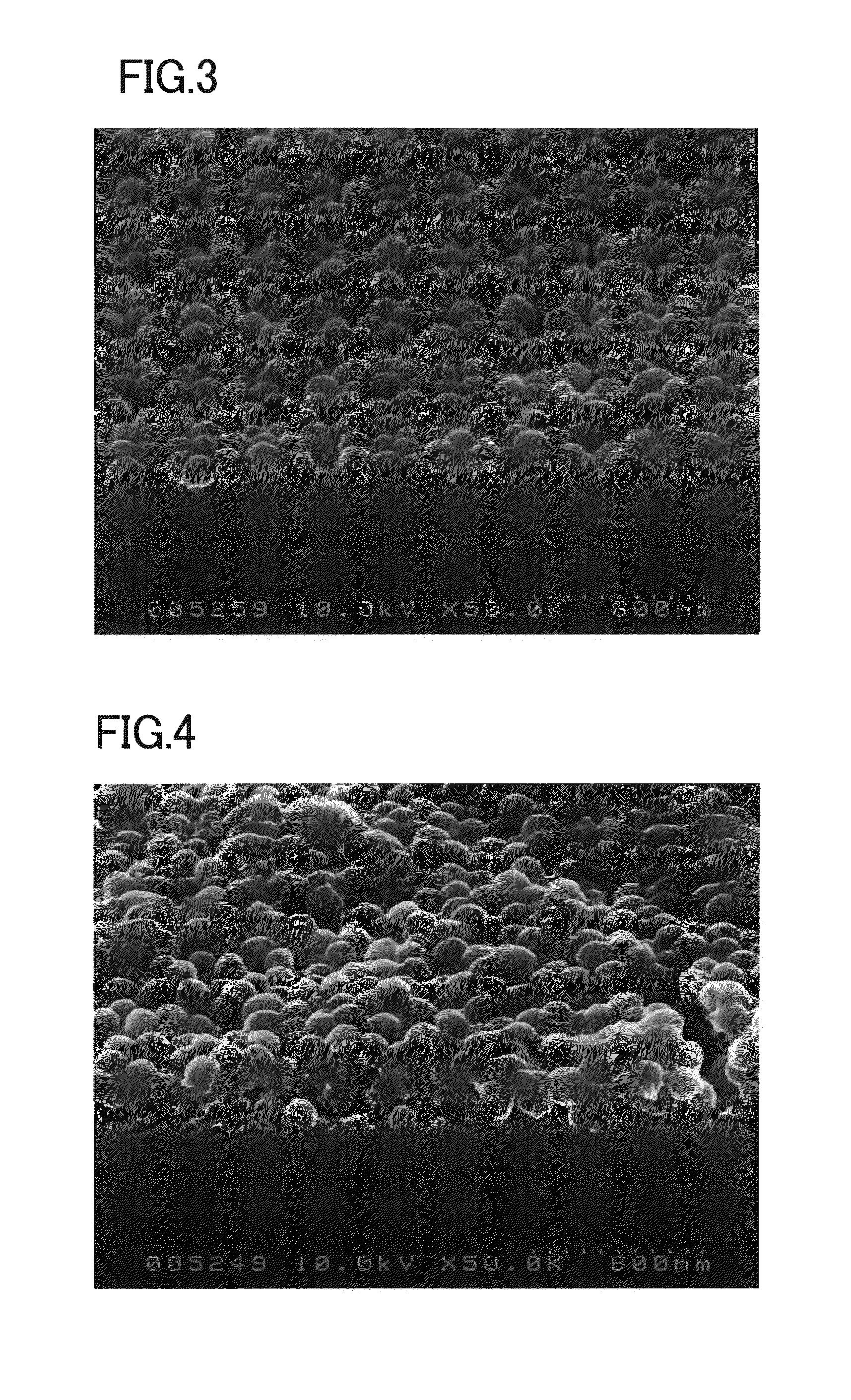

[0070]Using a figured glass having the surface shape shown in Table 1 and a coating solution prepared as shown in Table 1, a cover glass was obtained in the same manner as in Example 1. The resultant cover glass of each Example was evaluated for the above-mentioned properties. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| arithmetic average roughness Ra | aaaaa | aaaaa |

| arithmetic average roughness Ra | aaaaa | aaaaa |

| arithmetic average roughness Ra | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com