Oil field test and separation system

a separation system and oil field technology, applied in separation processes, liquid degasification, chemistry apparatus and processes, etc., can solve the problems of inaccurate metering when, the current device and method does not satisfactorily address all the prior problems, and the cost of testing and measuring equipment, etc., to achieve accurate fluid measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

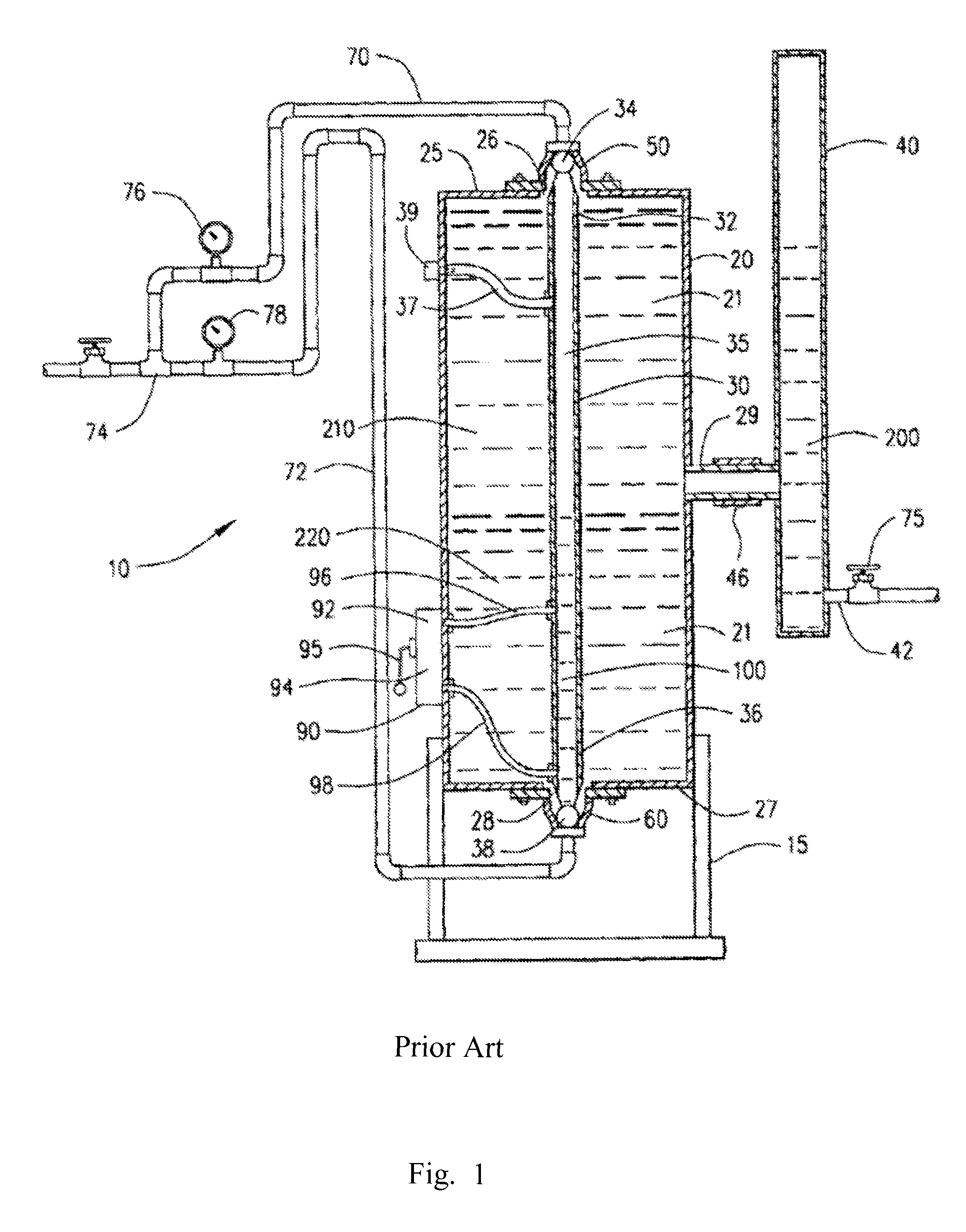

[0025]FIG. 1 shows the system of prior art U.S. Pat. No. 6,736,964 herein incorporated by reference an apparatus for separating and measuring mixed fluids, directed especially towards the separation of crude oil and water and the volumetric measurement of each of the primary constituent fluids, the apparatus 10 comprising essentially a vertically oriented cylindrical vessel 20 positioned on a support frame 15, the vessel 20 having an interior 21, an exterior surface, an upper outlet 26 located in a top portion 25 of the vessel 20, a lower outlet 28 located in a bottom portion 27 of the vessel 20 and an inlet 29 located approximately half way between the top portion 25 and bottom portion 27 from the exterior surface into the interior 21 of the vessel 20, an adjustably buoyant vertical float member 30 positioned within the interior 21 of the vessel 20, the float member 30 having an upper end 32 and a lower end 36, an upper housing 50 attached to the upper outlet 26, a lower housing 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com