Electronic module and method for the production thereof

a technology of electronic modules and production methods, applied in the direction of electric apparatus casings/cabinets/drawers, printed circuit non-printed electric components association, vehicle sub-unit features, etc., to achieve cost-effective, convenient to use, and easy to be equipped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

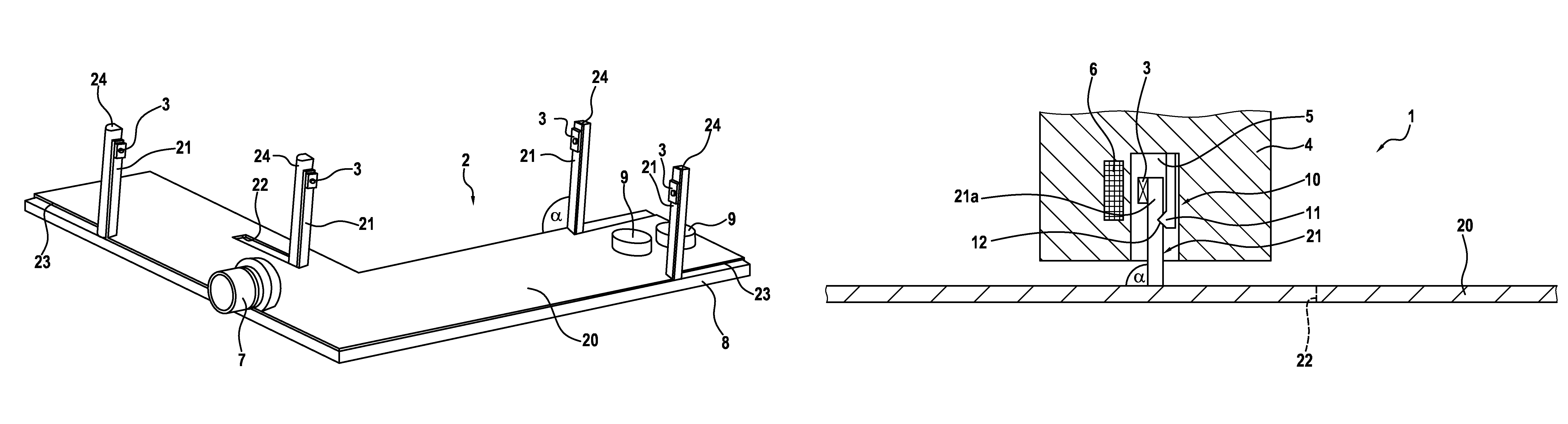

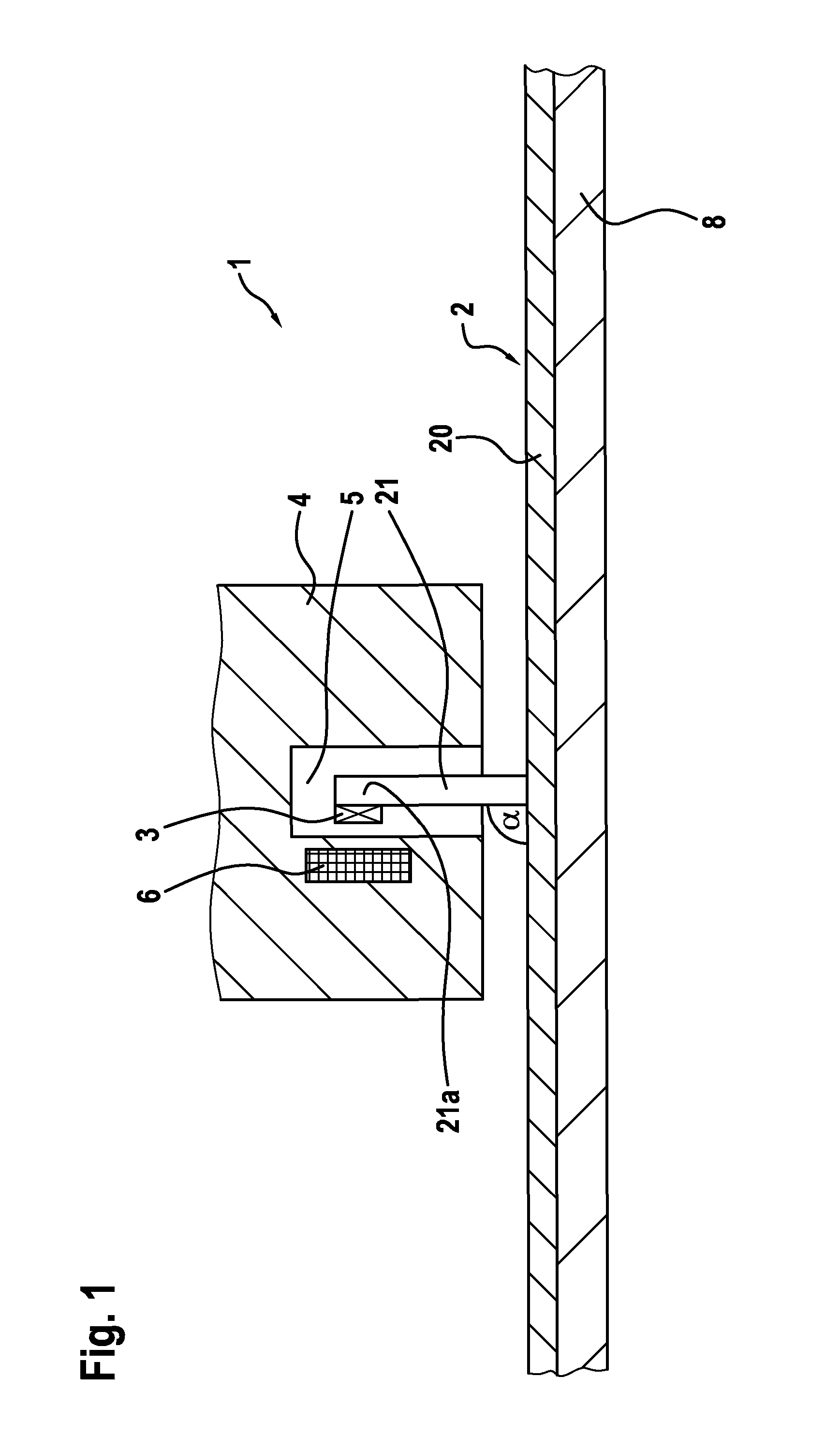

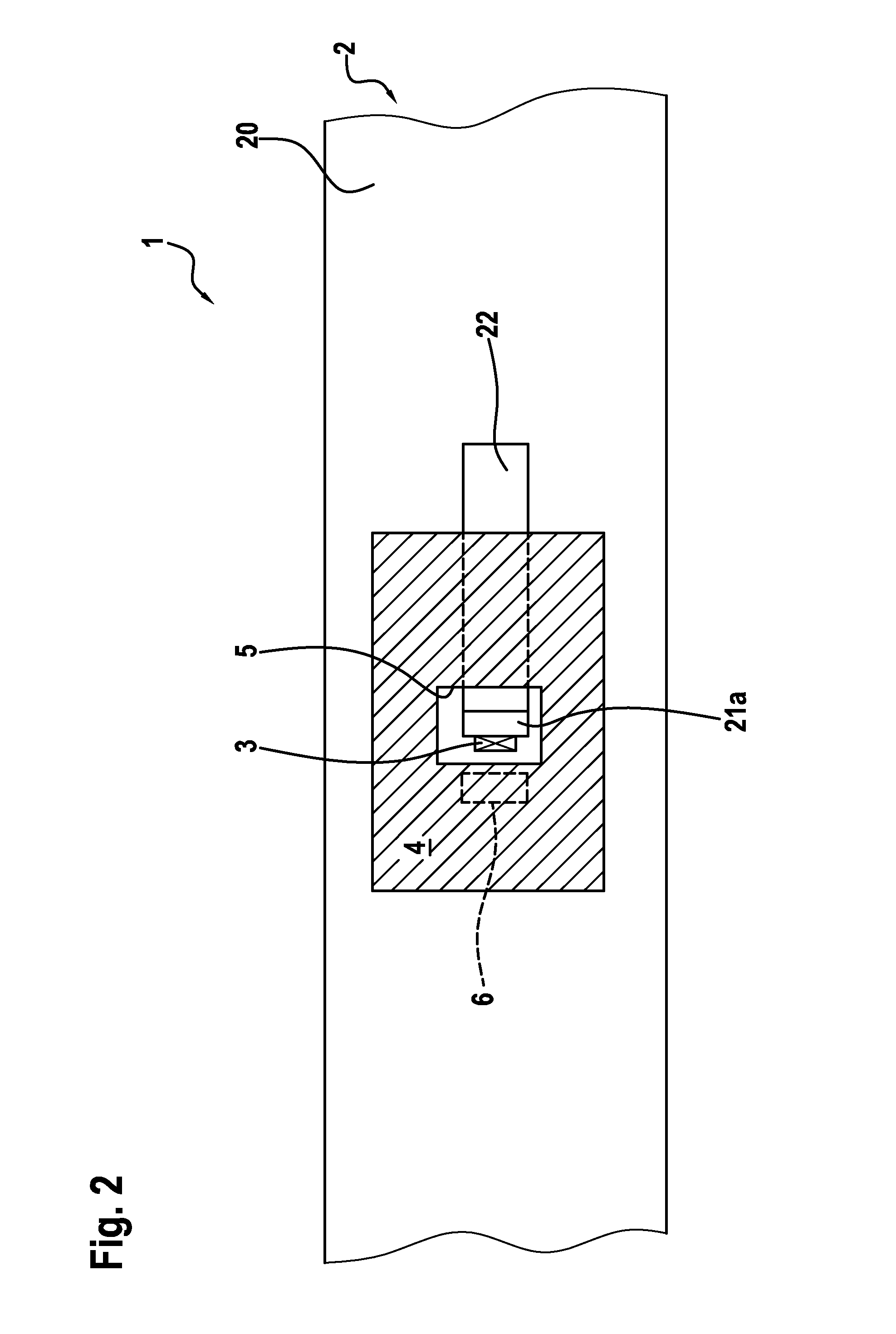

[0017]An electronic module 1 pursuant to a first preferred exemplary embodiment of the invention is described below in detail with reference to FIGS. 1 to 3.

[0018]As can especially be seen from FIG. 1, the electronic module 1 comprises a support plate 2, which is a printed circuit board in this exemplary embodiment. The support plate 2 has a base area 20 and a plurality of connection elements 21 (cf. FIG. 3), which are tilted upward from the base area 20 at an angle α of 90°. The printed circuit board is thereby an inexpensive, extensive printed circuit board and serves as a connection printed circuit board. The electronic module 1 further comprises electronic and / or electric components 3, which are sensors in this exemplary embodiment. The sensors are thereby in each case disposed in an end portion 21a of the connection elements 21.

[0019]The connection elements 21 can be produced by means of milling one side of the support plate, a recess 23 being formed in an edge region of the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| non-zero angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com