Multiple purpose wringer and method of wringing articles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The present invention of a multiple purpose wringer provides a versatile wringer which can wring a wide variety of types and sizes of mops, wipes, sponges and other wringable materials through a relatively simple mechanism which is easy to clean and minimizes any possible creation of secondary contaminants such as metal particles or lubricants.

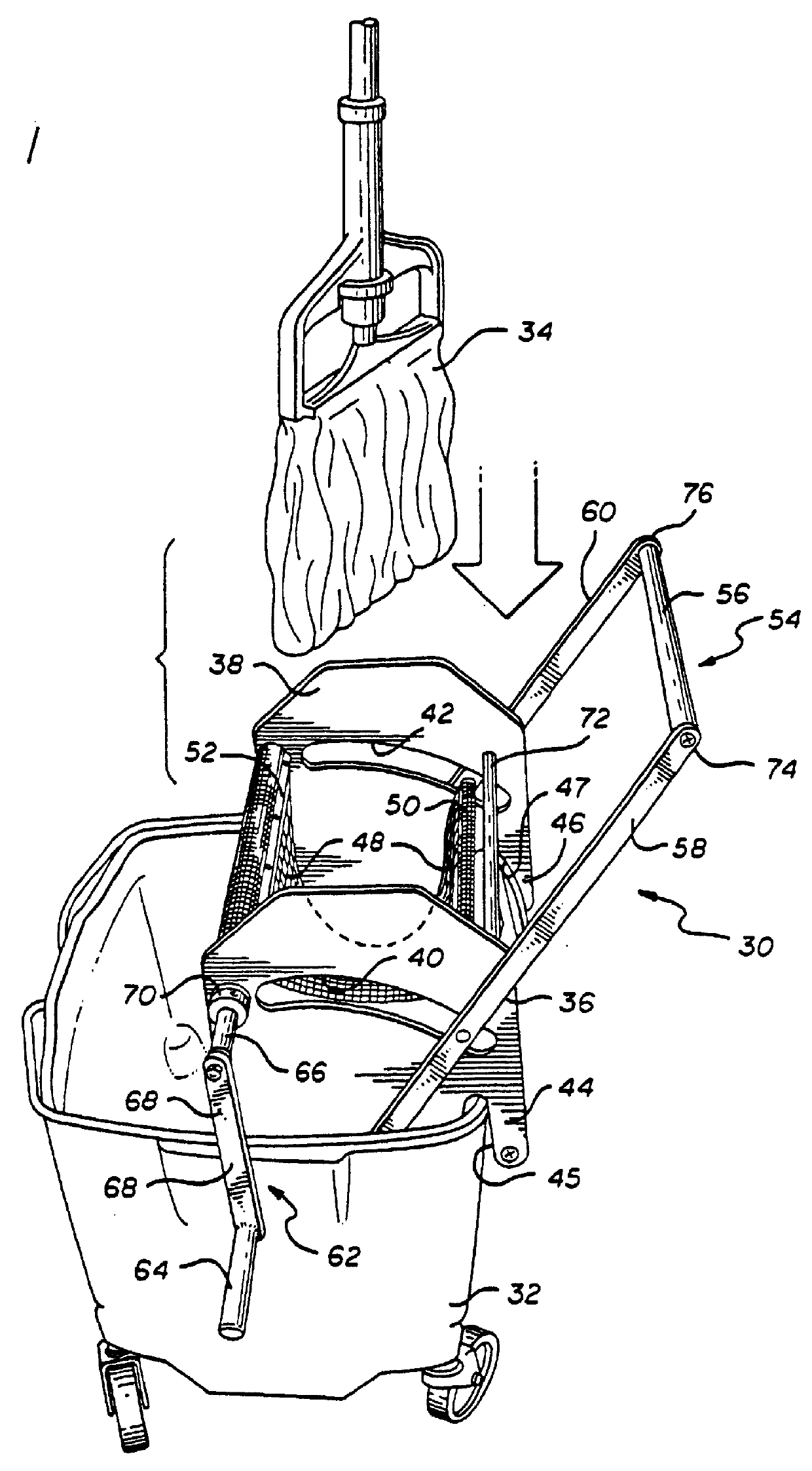

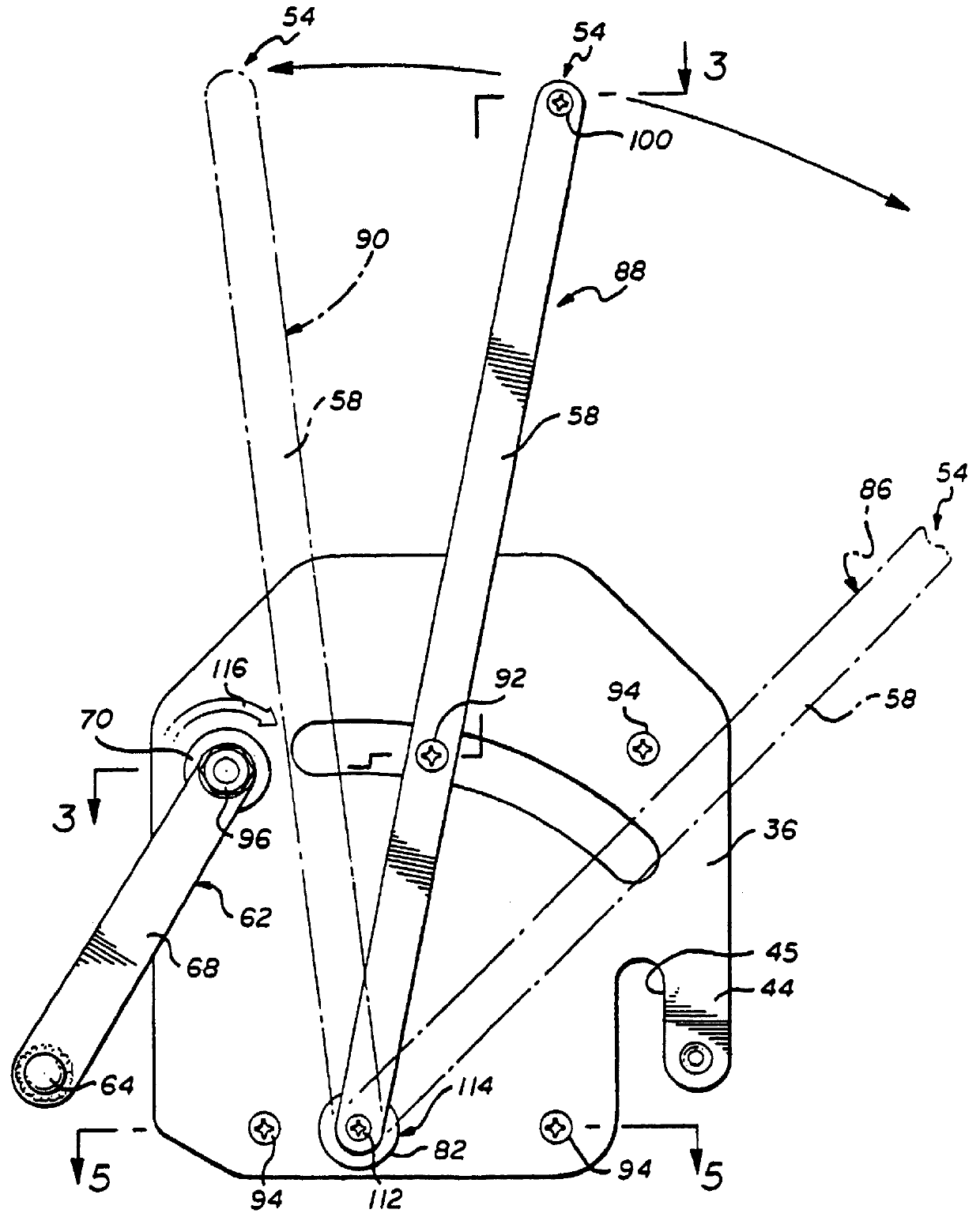

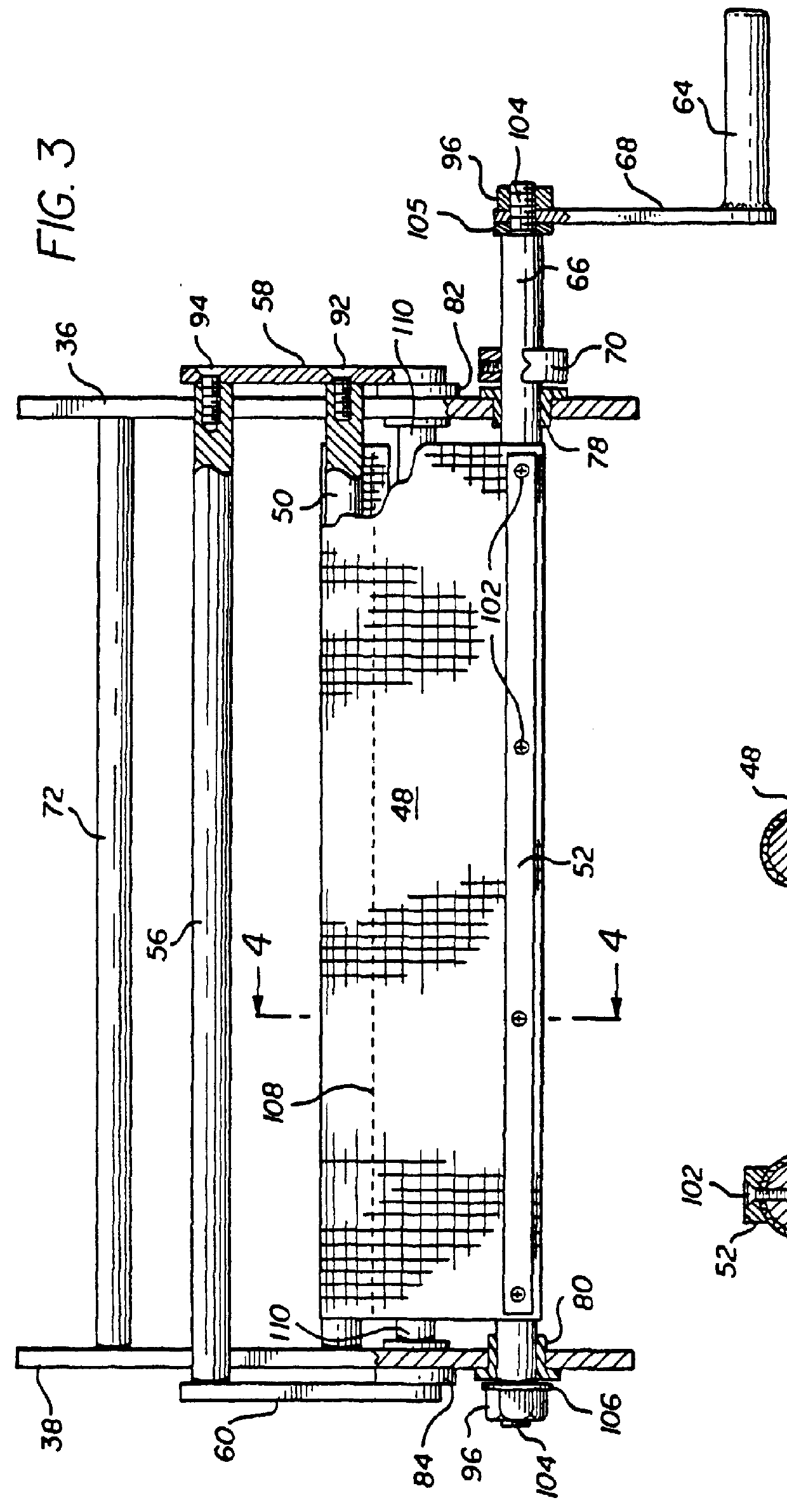

One preferred embodiment of a wringer 30 in accordance with the present invention is shown in FIG. 1 on a bucket 32. The wringer 30 is shown in an open position and is ready to receive a mop 34. The wringer in the preferred embodiment has first and second stainless steel side plates 36, 38 forming part of a frame for purposes of rigidity and stability which have side plate slots 40, 42 and first and second bucket mounts 44, 46. A web 48 is positioned in the frame so that the web can accept a wringable item and close around the wringable item so as to wring the item, preferably by applying uniform pressure over as much of the item as possible. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com