Method for constructing a synthetic infiltration collection system

a collection system and synthetic technology, applied in the field of desalination of seawater, can solve the problems of hydrocarbon products in feed water, biological fouling of intake pipes, and high production costs of fresh water, and achieve the effect of eliminating dependency on local nearshore geology and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

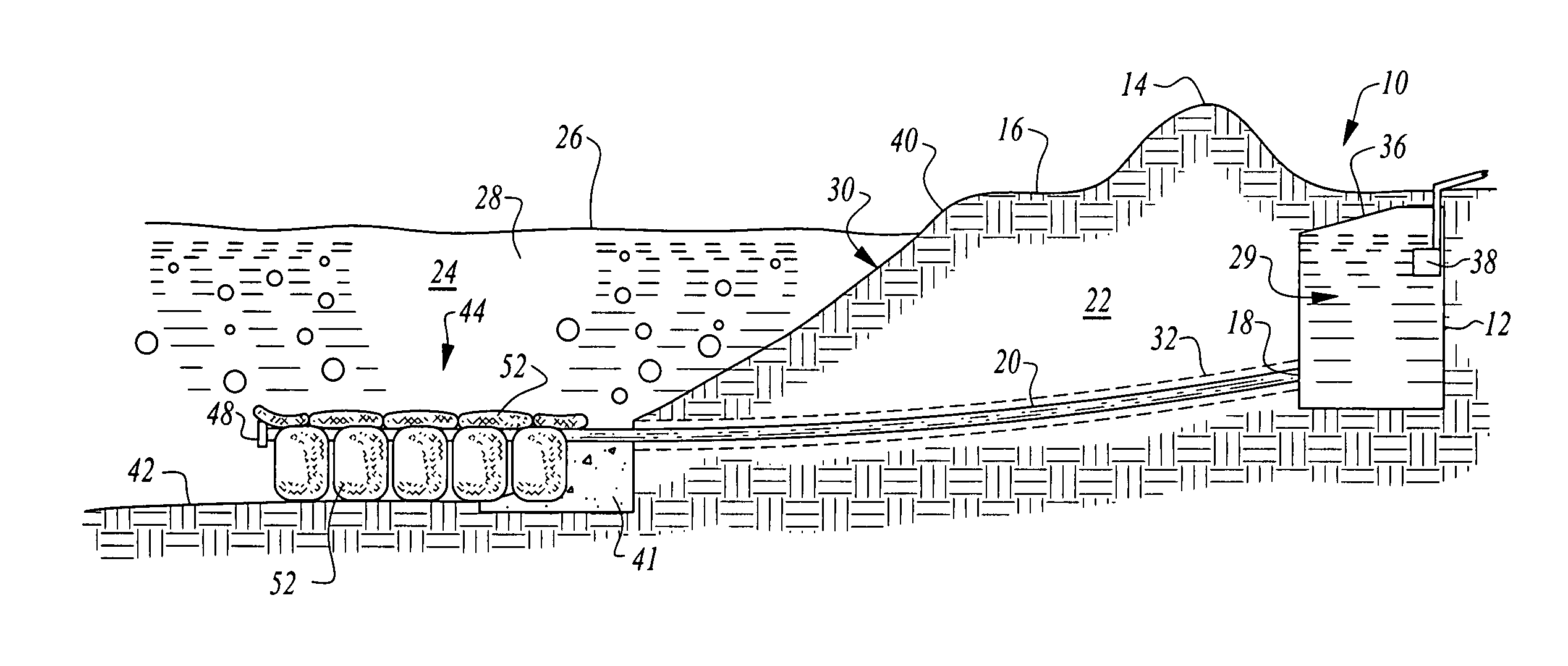

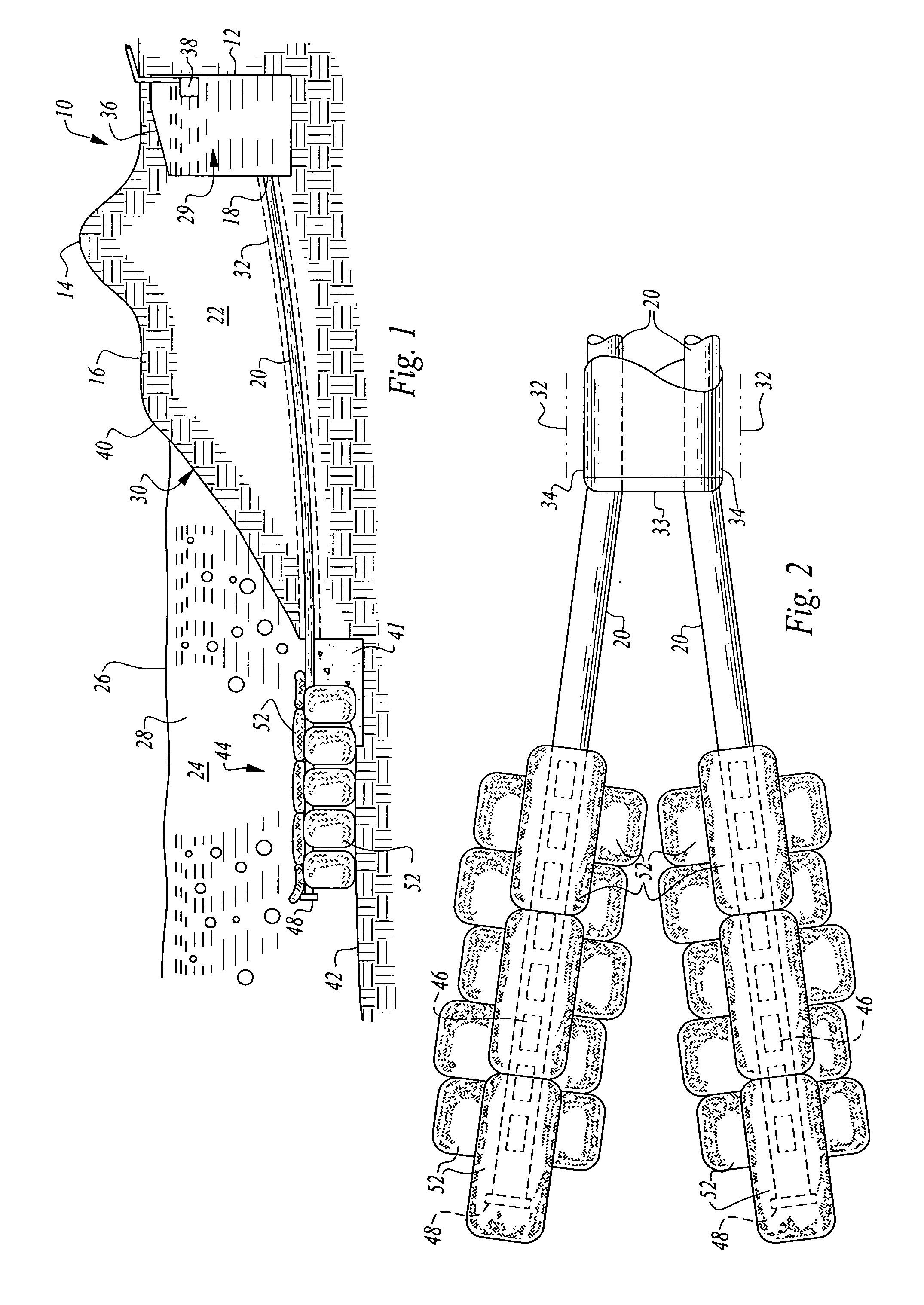

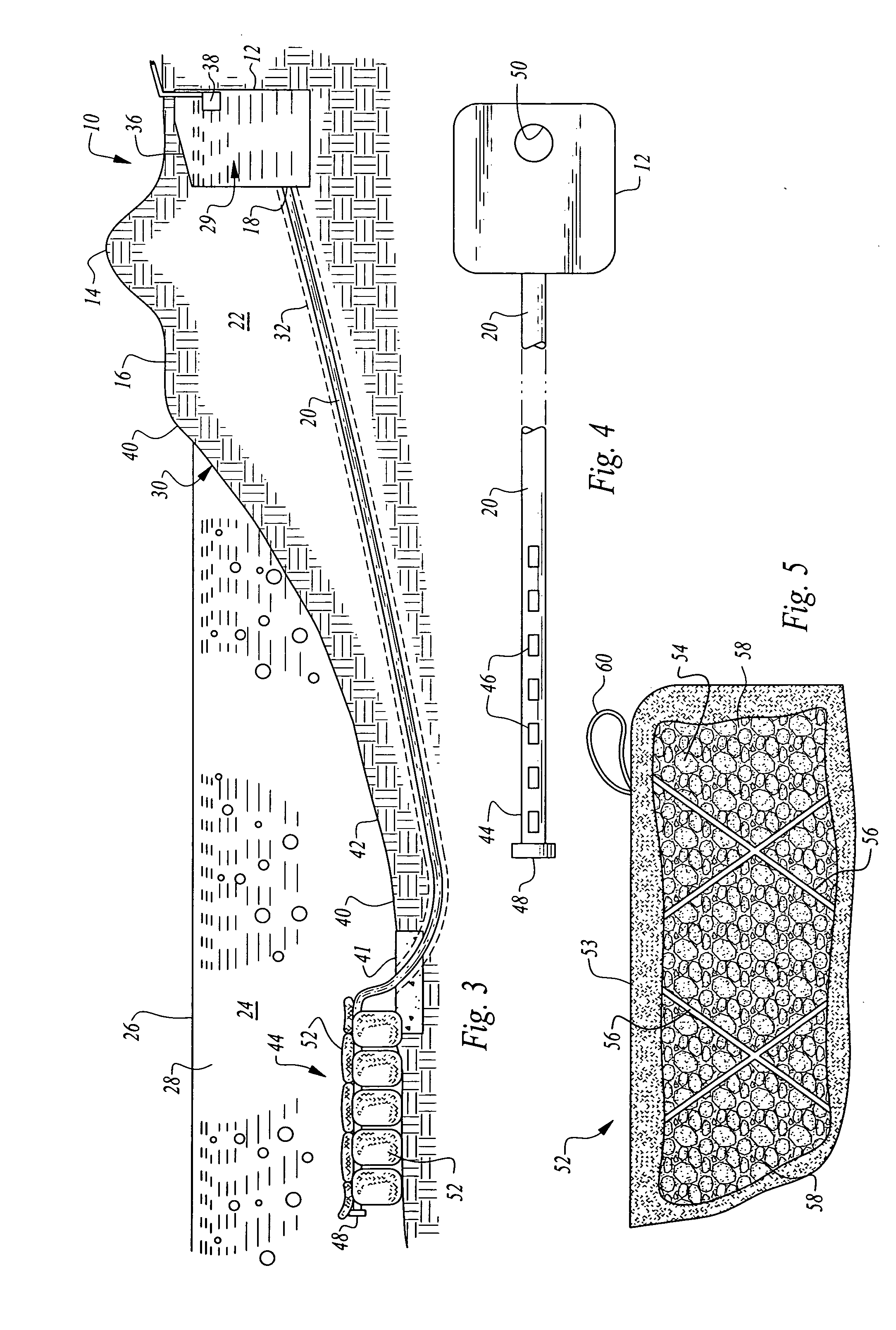

[0027] Referring to FIG. 1, a preferred embodiment of the filtered seawater collection system 10 constructed by the inventive method is shown. The system 10 is comprised of a subterranean reservoir 12 that is preferably sunk in the ground at an area that is protected from wind, beach erosion, littoral drift, storm surges and other damaging coastal forces. Here, the reservoir 12 is shown sunk behind a first set of dunes 14 adjacent to a beach 16. The reservoir 12 is connected to a first end 18 of an intake pipe 20, and the pipe 20 extends outward from the reservoir 12 through the nearshore 22 and out into the open ocean 24. The nearshore 22 as shown is a geologic area below the beach 16 and below sea level 26. In some coastal regions, the nearshore 22 has a porous geology, which allows seawater 28 to filter down free of biological material and debris. However, in other coastal regions the nearshore 22 has an all but impermeable geology. As noted previously herein, the geology of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com