Optical fiber ferrule connector having enhanced provisions for tuning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

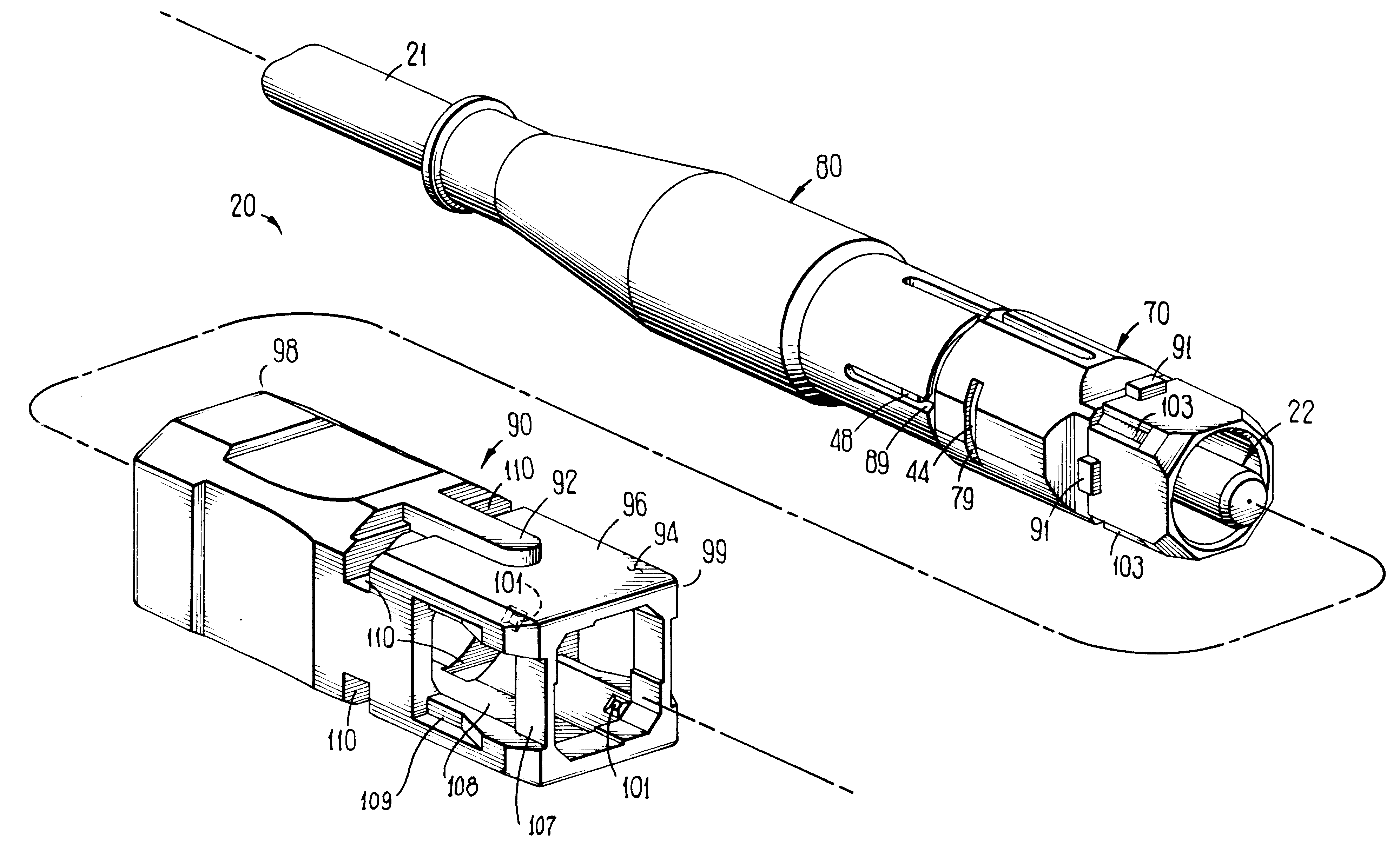

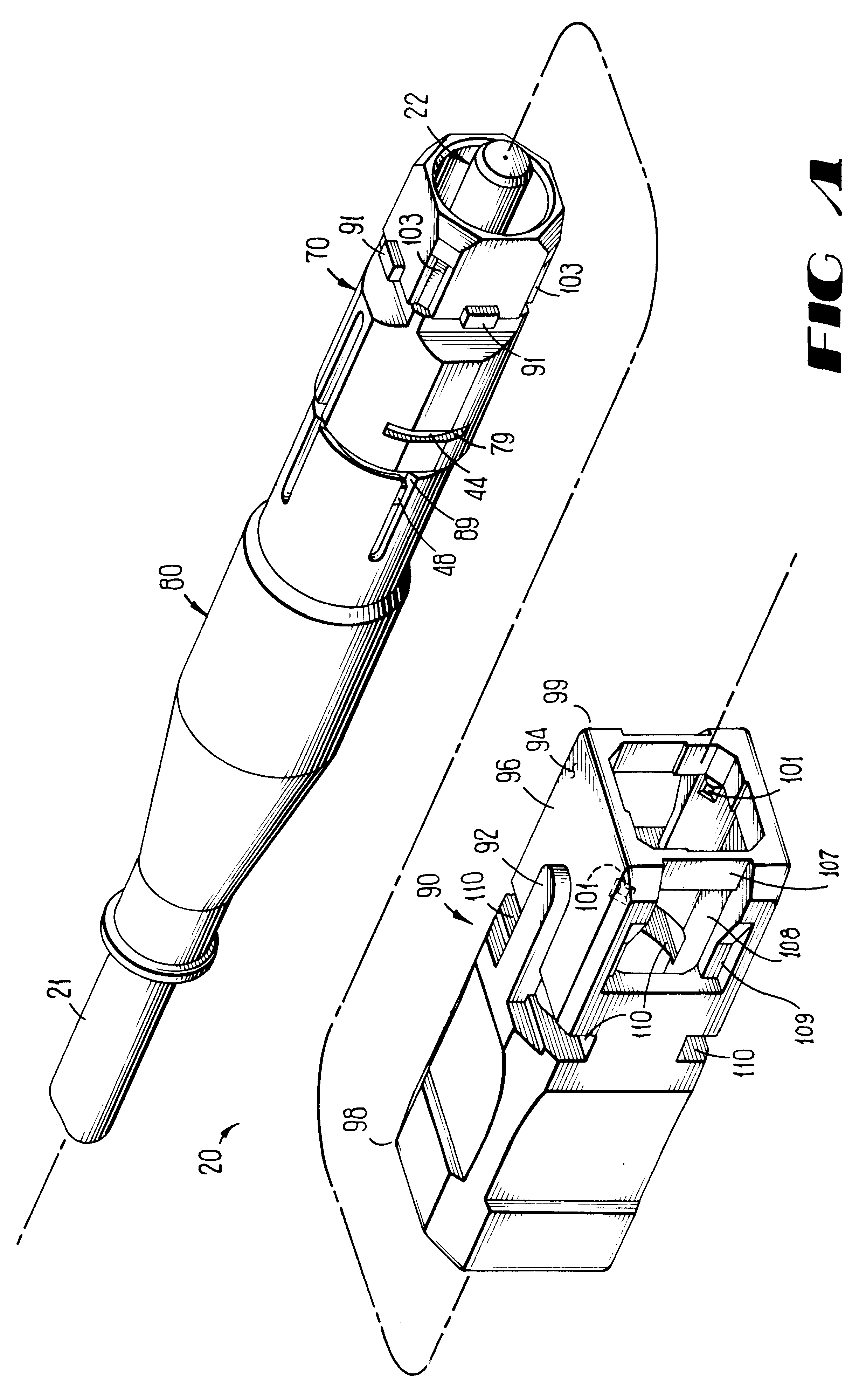

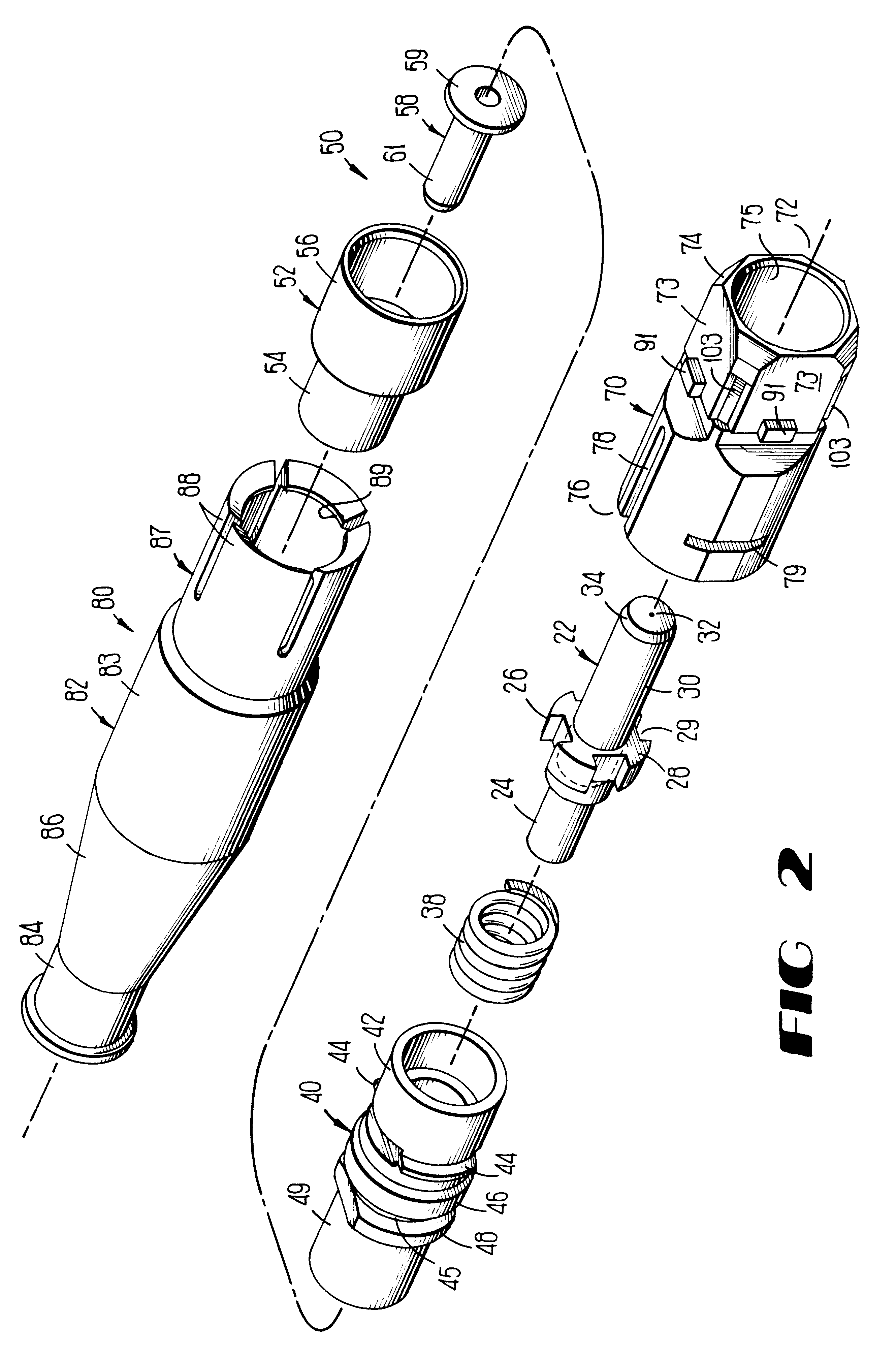

Referring now to FIG. 1, there is shown a connector which is designated generally by the numeral 20 which is adapted to terminate an optical fiber cable 21. The connector 20 comprises a ferrule assembly which is designated generally by the numeral 22. The ferrule assembly includes a barrel 24 (see also FIG. 2) having a segmented collar 26 at one end thereof. For the purpose of antirotation the collar 26 is provided with segments 28-28 with a groove 29 formed between each adjacent two of the segments. Four segments 28-28 are preferred but more or less could be used. Extending from a cavity in an opposite side of the collar 26 is a ferrule 30 which is made of a ceramic material, for example, and which has an optical fiber receiving passageway 32 formed along a longitudinal centerline axis thereof. Further, a free end of the ferrule 30 has a beveled portion 34 which facilitates insertion of the ferrule into an alignment device. In order to facilitate the insertion of one end portion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com