Ink jet print head

a printing head and jet technology, applied in the field of jet printing head, can solve the problems of reducing the quality of recording, affecting the printing, and stopping the discharge, so as to avoid the effect of the subsequent discharge and shorten the damping time of the meniscus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Detailed below is a preferred embodiment of the present invention, with reference to FIGS. 4 to 11. Like members are designated by like reference characters.

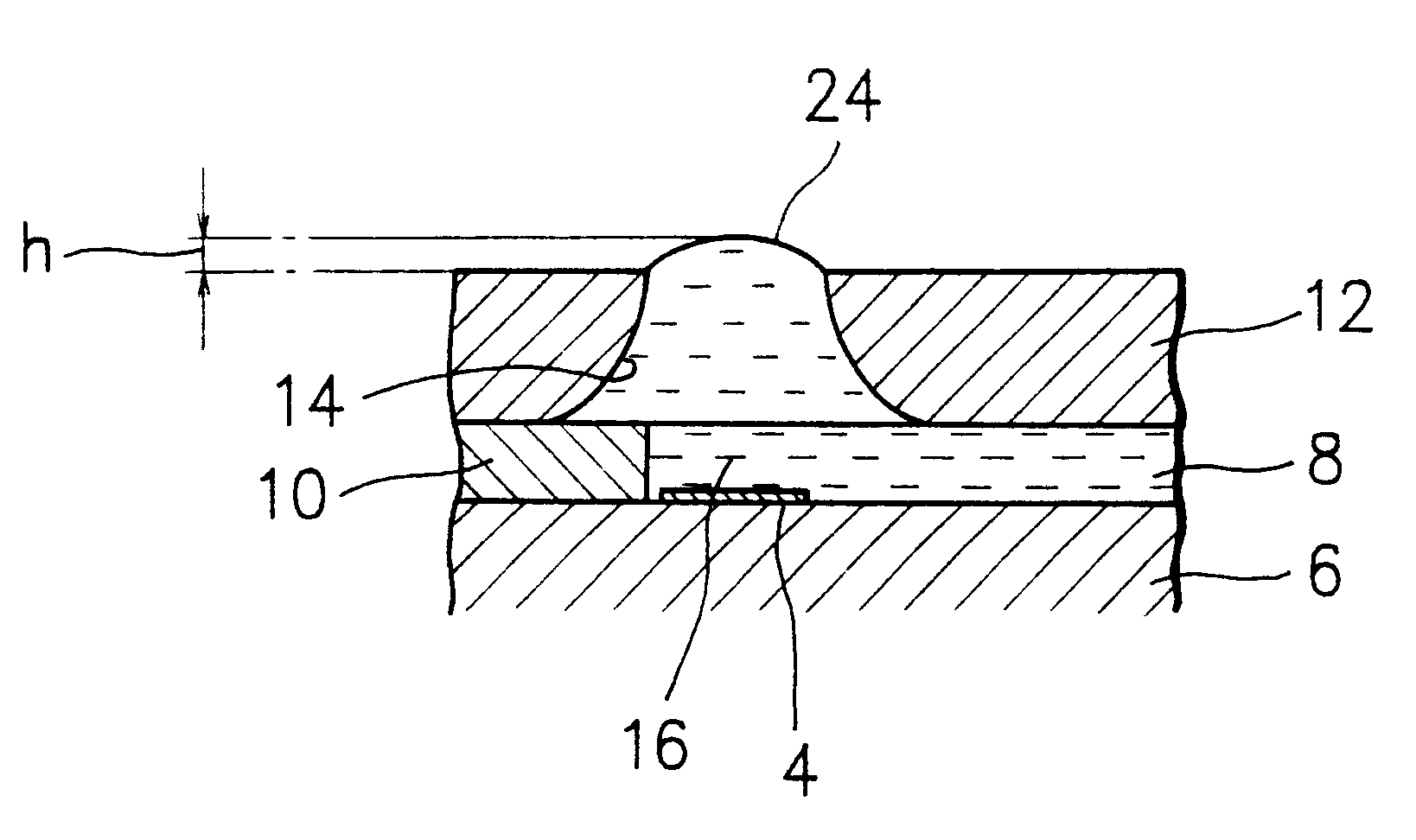

Referring now to FIG. 4, an ink jet print head 1 according to an embodiment of the invention comprises a substrate 6 formed with a plurality of heating resistors (hereafter collectively "heating resistor") 4 and a central recess or groove 6a used as an ink pool or trunk path. An ink path defining resin sheet member 10 defines a plurality of channels as branched ink supply paths (hereafter collectively "ink supply path") each including a heating zone. An orifice plate 12 is formed with a plurality of orifices or nozzles as ink outlets 14 (hereafter collectively "ink outlet").

FIG. 5 shows a cross sectional view of a nozzle of an ink jet print head (multi-nozzle) identical to the print head 1. FIG. 6 shows a plan view of Ie ink jet print head with an orifice plate removed.

An ink jet print head 2 is provided with a substrate 6, a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com