Method and apparatus for cementing a well

a well and cementing technology, applied in the direction of fluid removal, sealing/packing, borehole/well accessories, etc., can solve the problems of large volumes of cuttings, heavy logistics, and inability to usefully complete the well, and achieve the effect of reducing the diameter section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

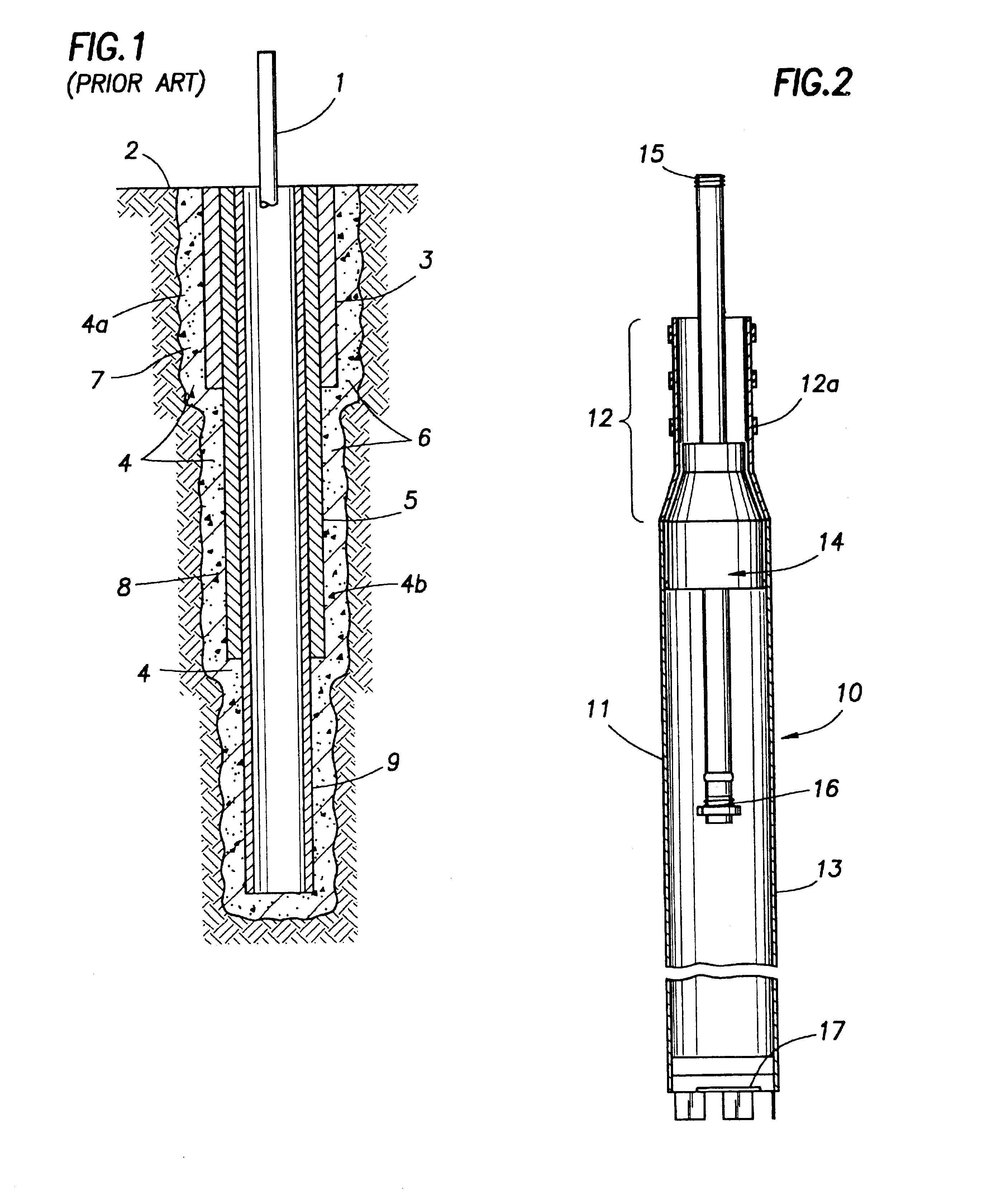

For a fuller understanding of the invention, reference is made to the drawing. Accordingly, in FIG. 1 there is shown a well string 1 extending to the earth surface 2 and to conductor pipe or casing 3. Conductor pipe 3 is positioned in the portion 4a of wellbore 4, while pipe 5 is in reduced diameter section 4b of the same wellbore. The wellbore forms segmented annulus 6 with pipes 3 and 5, the width of the annulus segments being the same or approximately the same. A further reduced diameter section 9 is illustrated. As indicated, standard cementing operations provide a cemented annulus which stabilizes the wellbore, but the effective diameter of the conducting passage is progressively and substantially reduced as the well is deepened.

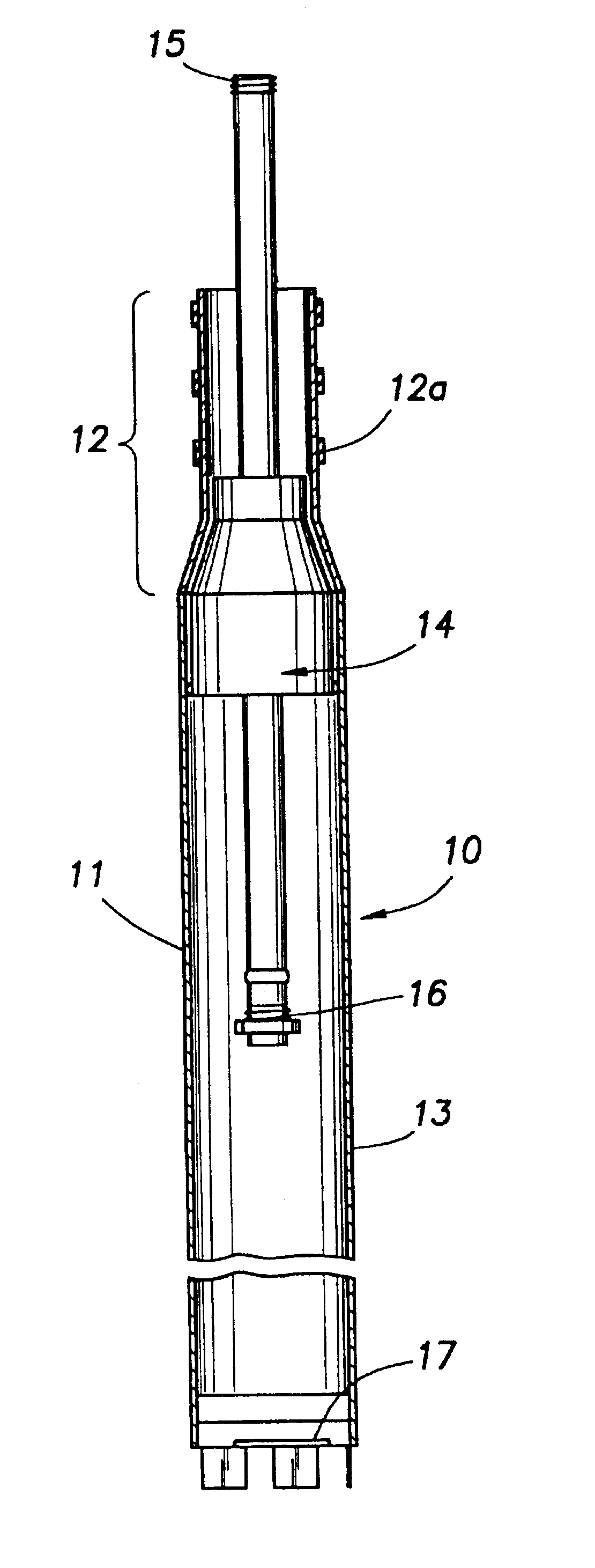

FIG. 2 illustrates an important aspect of the invention. Accordingly, in FIG. 2 there is shown a liner-die assembly designated generally as 10. The assembly includes the liner component 11 which, as shown, comprises a liner head section 12 which include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com