Infinitely variable epicyclic transmissions

a transmission and epicyclic technology, applied in the direction of gearing, gearing details, hoisting equipment, etc., can solve the problem of not being continuously adjustable, and achieve the effect of reliable manufacture and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

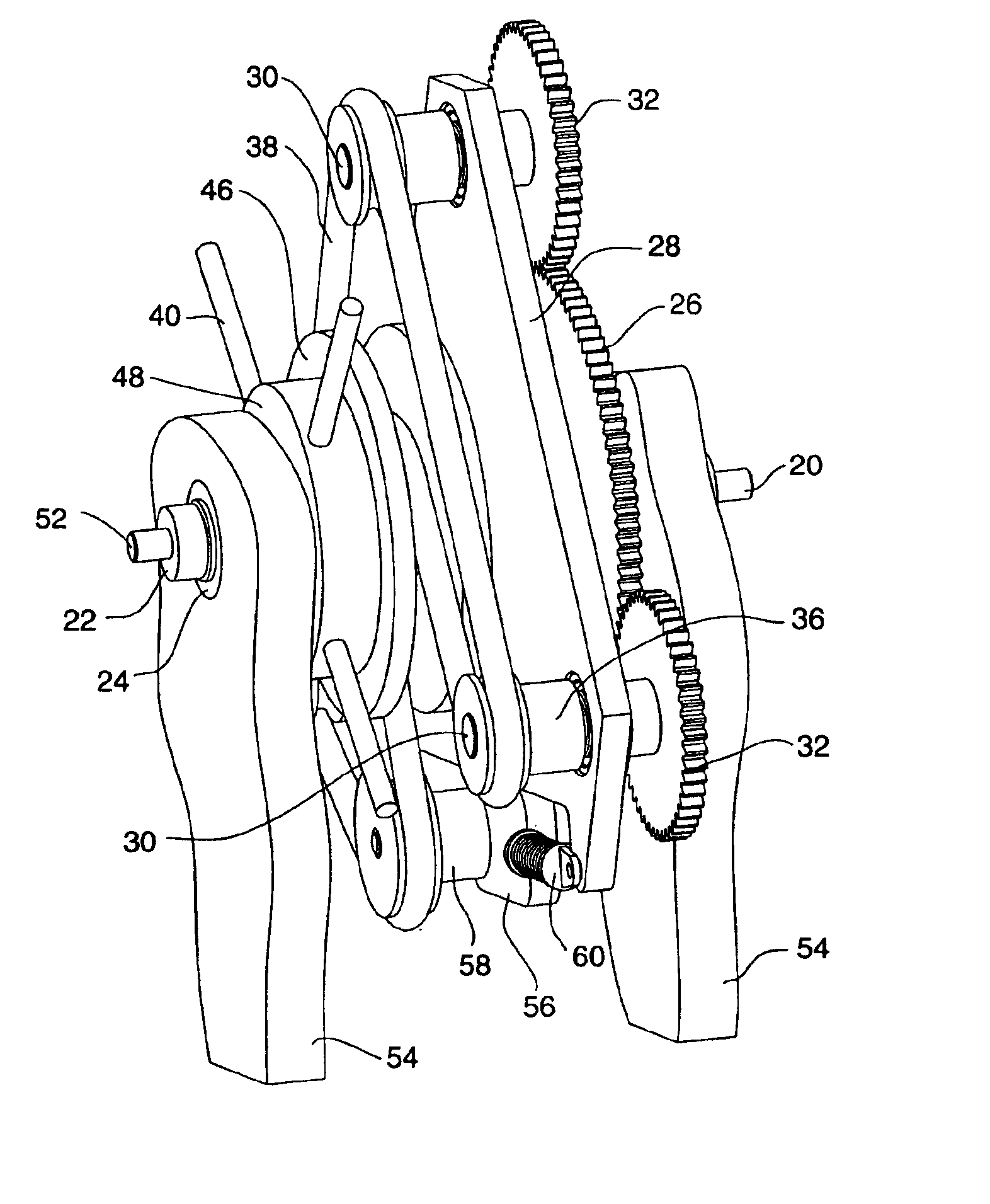

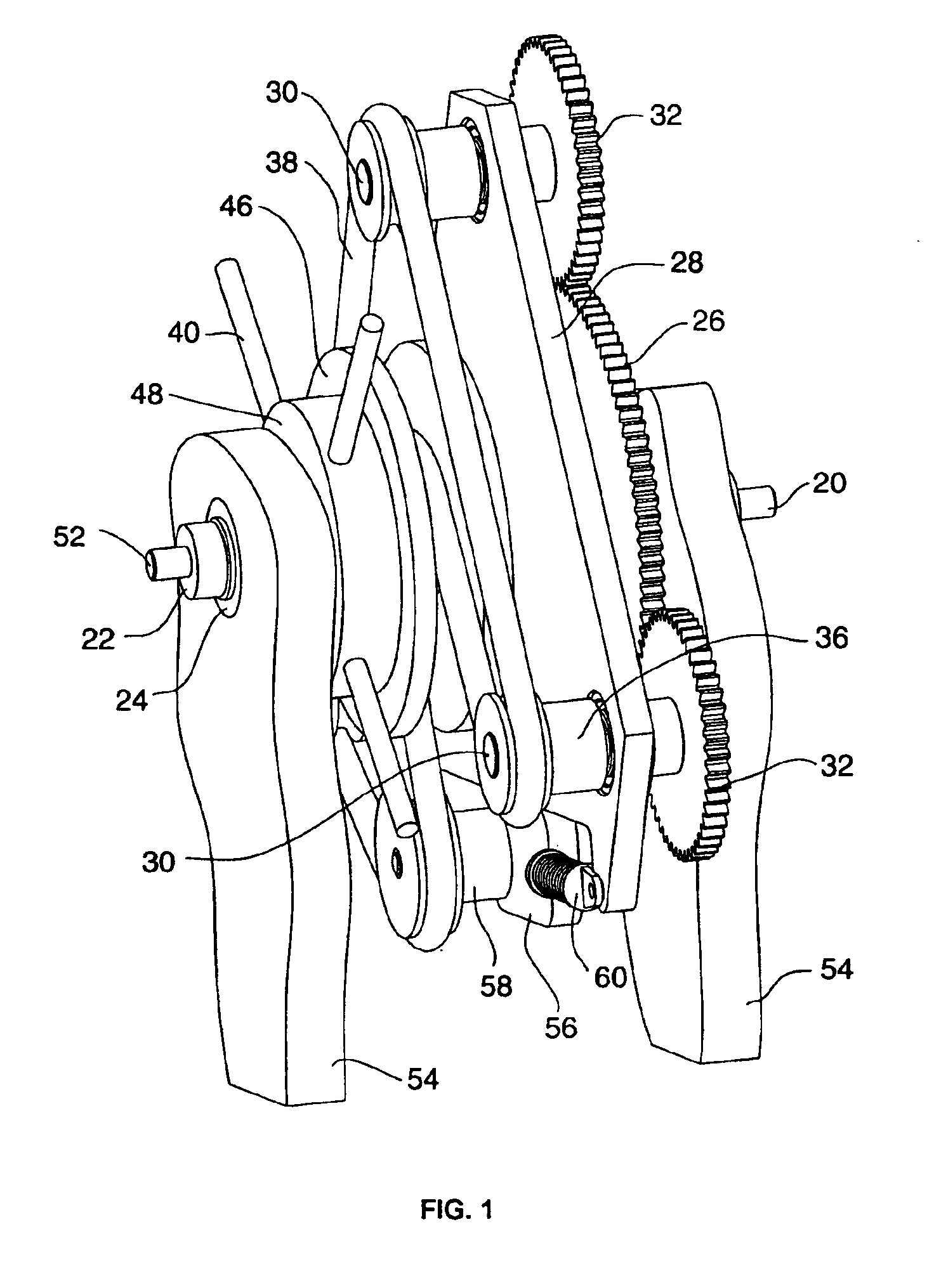

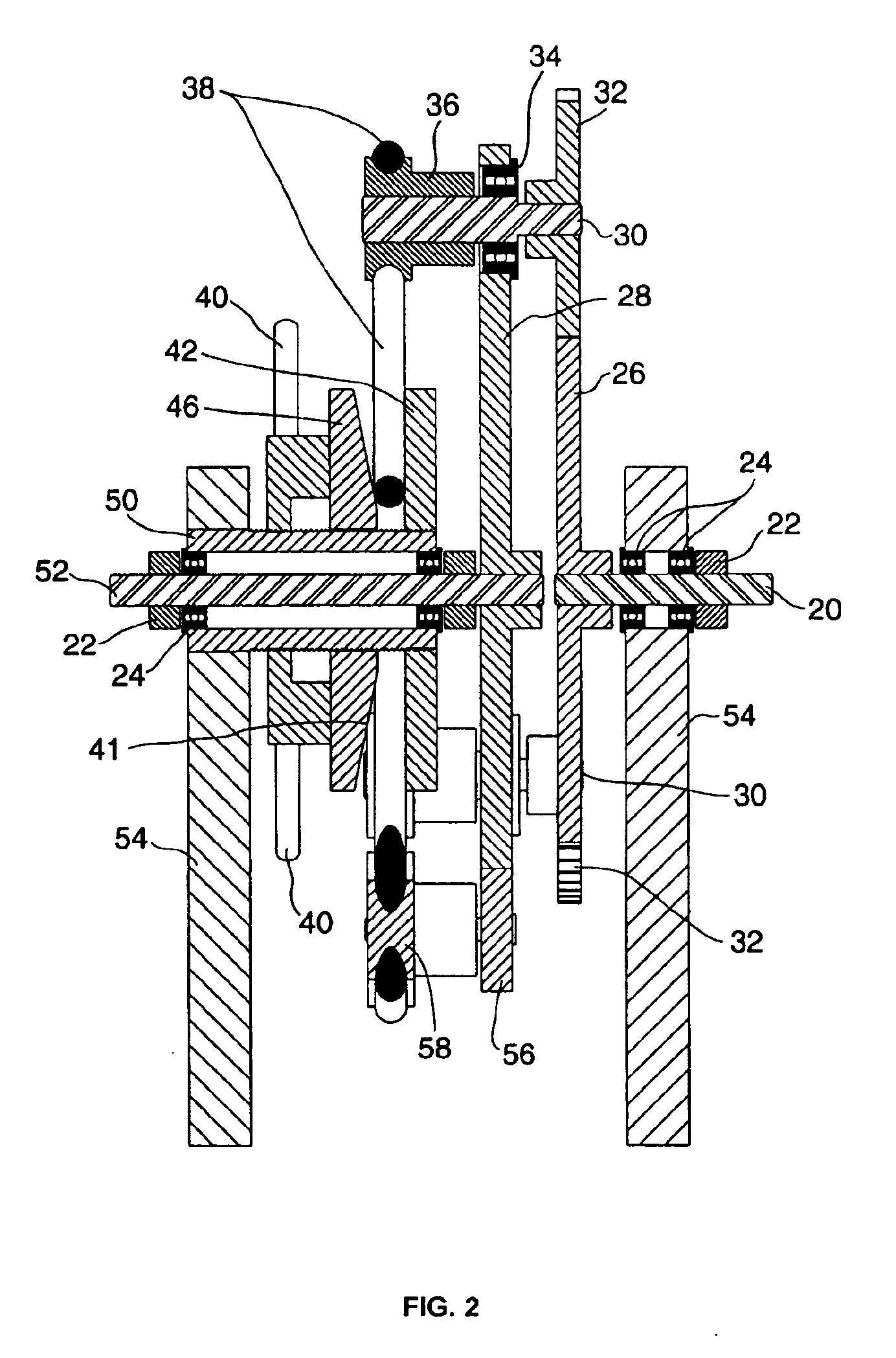

[0037]The invention has several desirable embodiments. All the embodiments offer the advantage of being simple, compact, and reliable. All embodiments are capable of continuously varying the output speed and torque through forward, neutral, and reverse while the input shaft remains constant in rotational speed and direction. Among other features shared by the various embodiments are compactness of both width and diameter; use of efficient epicyclic gear components to achieve an infinitely variable gear ratio, integral components allowing for direct, independent speed control of the planetary elements driven from the input shaft, coaxially aligned input and output shafts, and relatively small number of components for inexpensive, reliable manufacture. The inventive apparatus features independent control of various components of epicyclical gear systems to achieve output speeds that may be selectively varied continuously from forward, through neutral, and then into reverse (and vice ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com