Radial jaw biopsy forceps

a jaw biopsy and forcep technology, applied in the field of biopsy forceps, can solve the problems of complex construction of devices, requiring the manufacturing and machining of precise miniaturized components, and therefore generally quite expensive, and requiring expensive machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

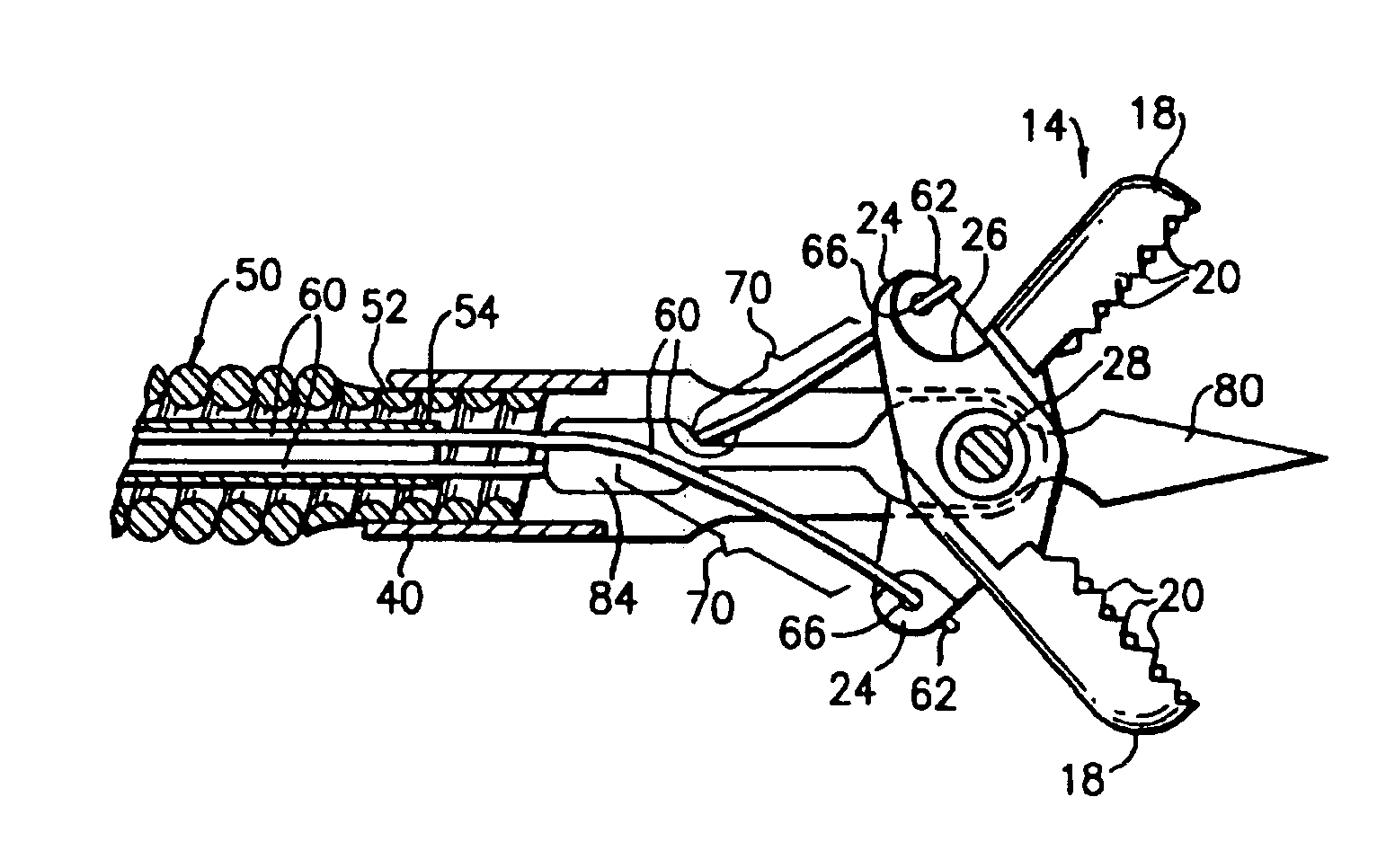

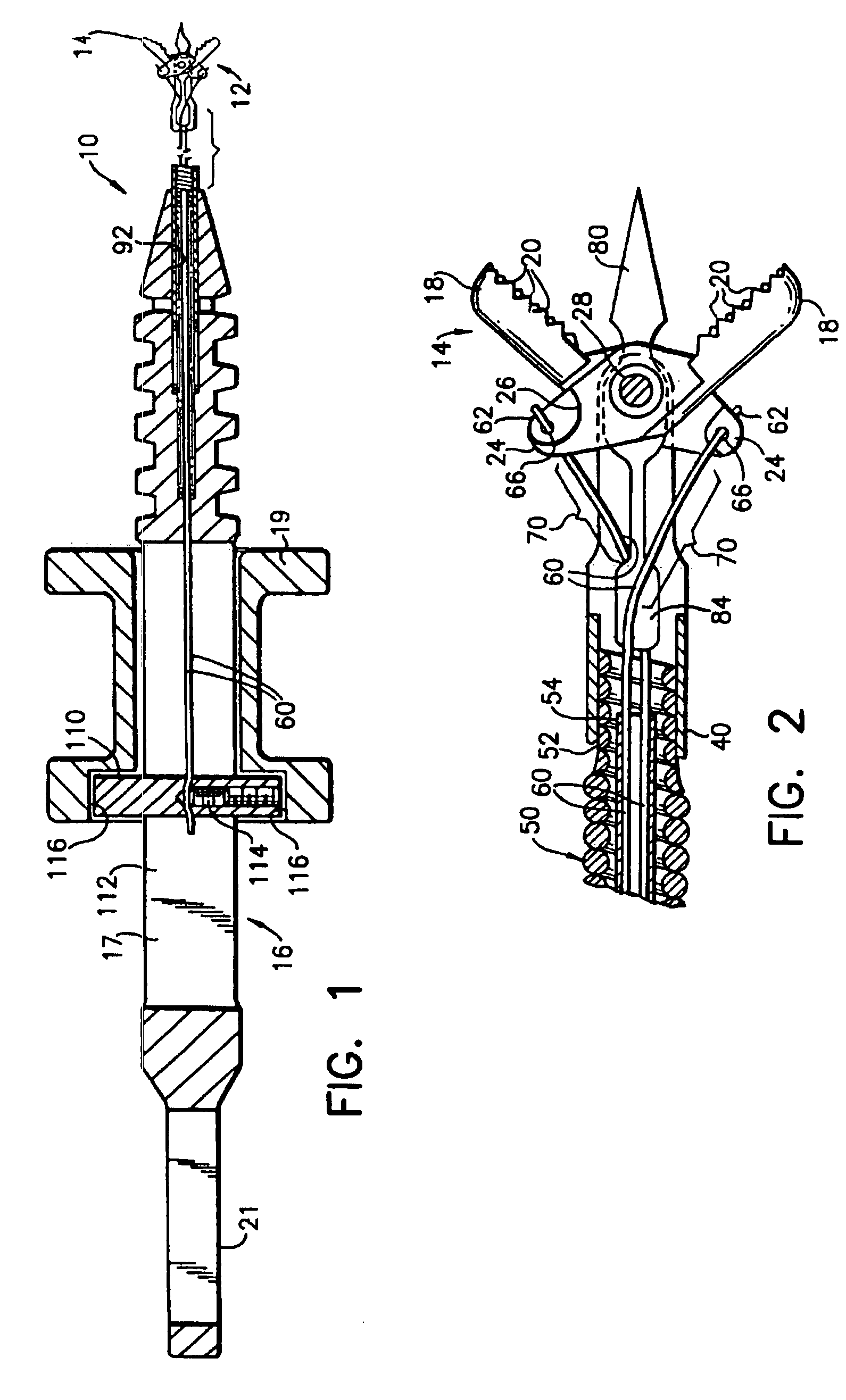

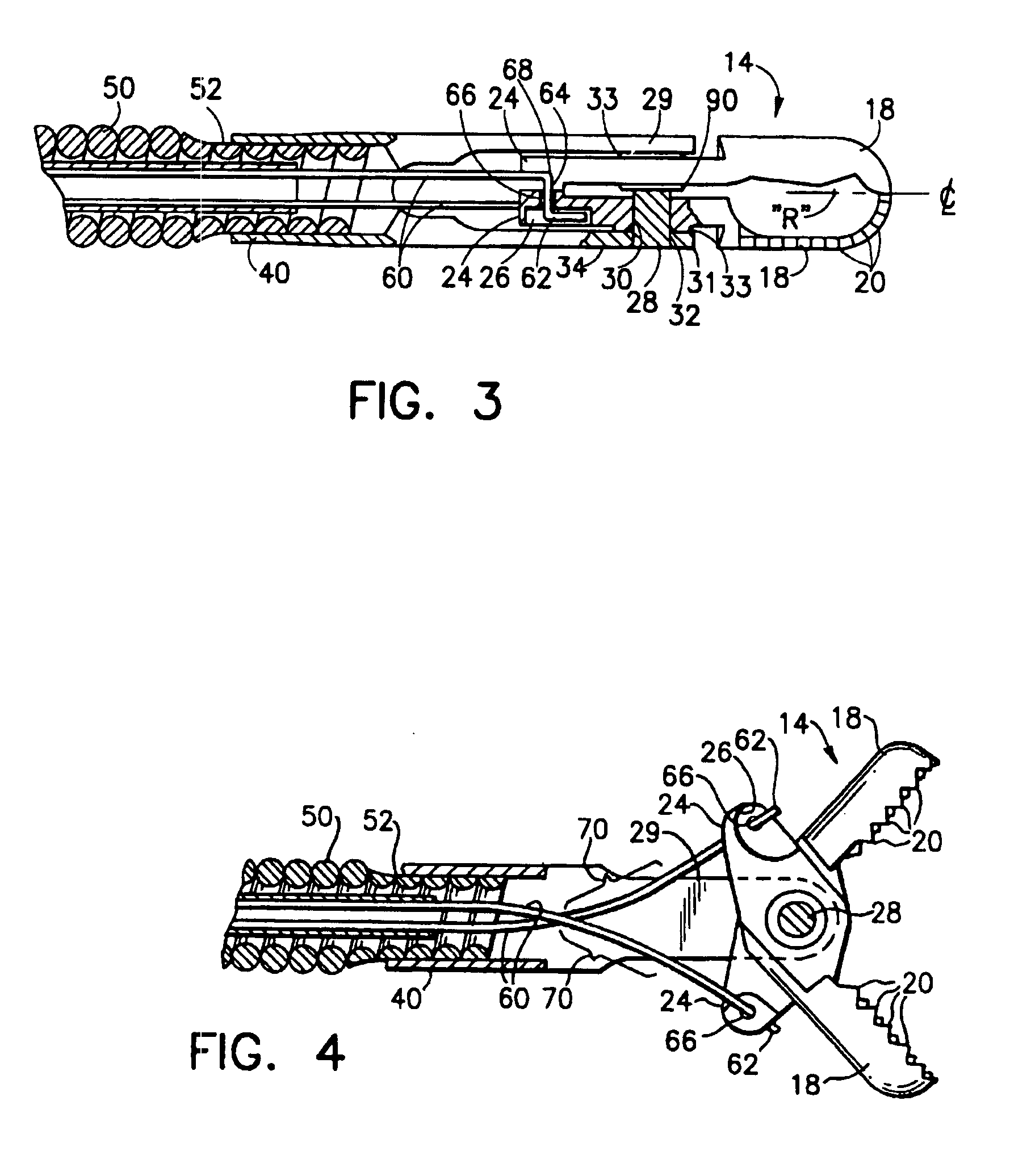

[0028]Referring now to the drawings in detail and particularly to FIG. 1, there is shown a biopsy forceps assembly 10, having a distal end 12, comprising a jaw assembly 14, and a proximal end 16 comprising a handle 17, spool 19 and thumb ring 21 for manipulation of the assembly. The jaw assembly 14 comprises a pair of jaws 18, each of which is a duplicate of the other. Each jaw 18 as may be seen in FIGS. 2 and 3, is a generally elongated somewhat hemispherically shaped structure having a distalmost end and a proximalmost end. Each jaw 18 has on its distalmost end, an array of teeth 20 generally radially directed about a point “R”, as exemplified in FIG. 3. Each jaw 18 has a generally longitudinal centerline as may be seen in FIGS. 3 and 5. The teeth 20 on one side of the longitudinal centerline of each jaw 18 being displaced by one half pitch from the corresponding teeth 20 on the other side of the longitudinal centerline on that jaw 18. The displacement by one half pitch by the tee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| triangular shape | aaaaa | aaaaa |

| elongated hemispherical shape | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com