Optical system of laser ruler

An optical system and laser ruler technology, which is applied in the field of laser rulers, can solve problems such as increased system instability factors, increased system manufacturing costs, and reduced system reliability, achieving high mass production of component processing, no moving components, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

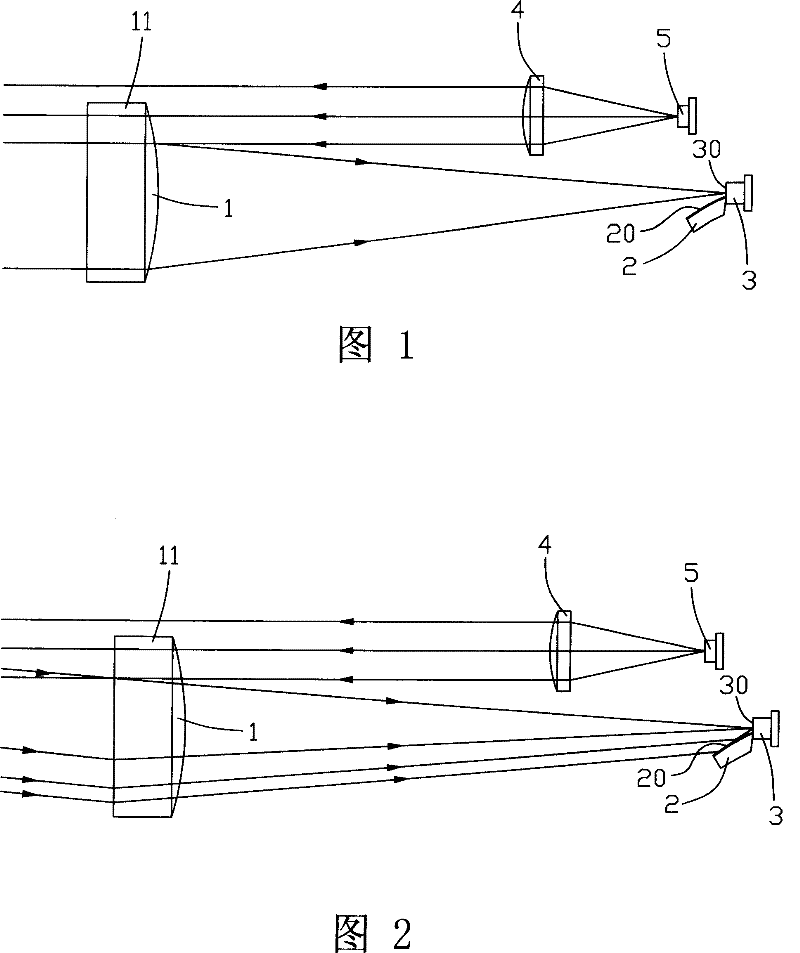

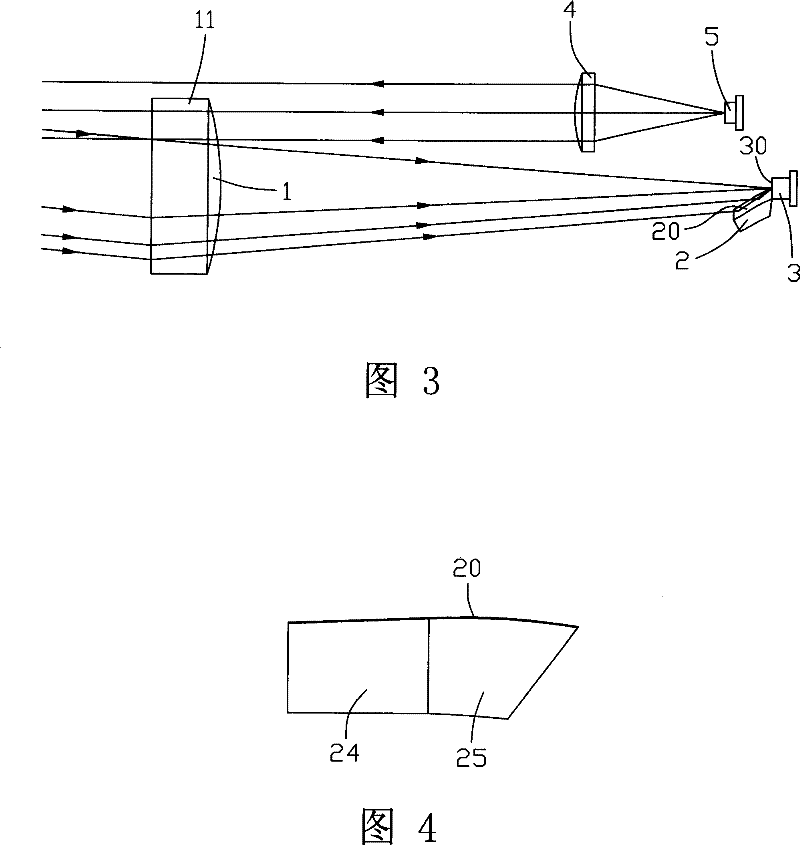

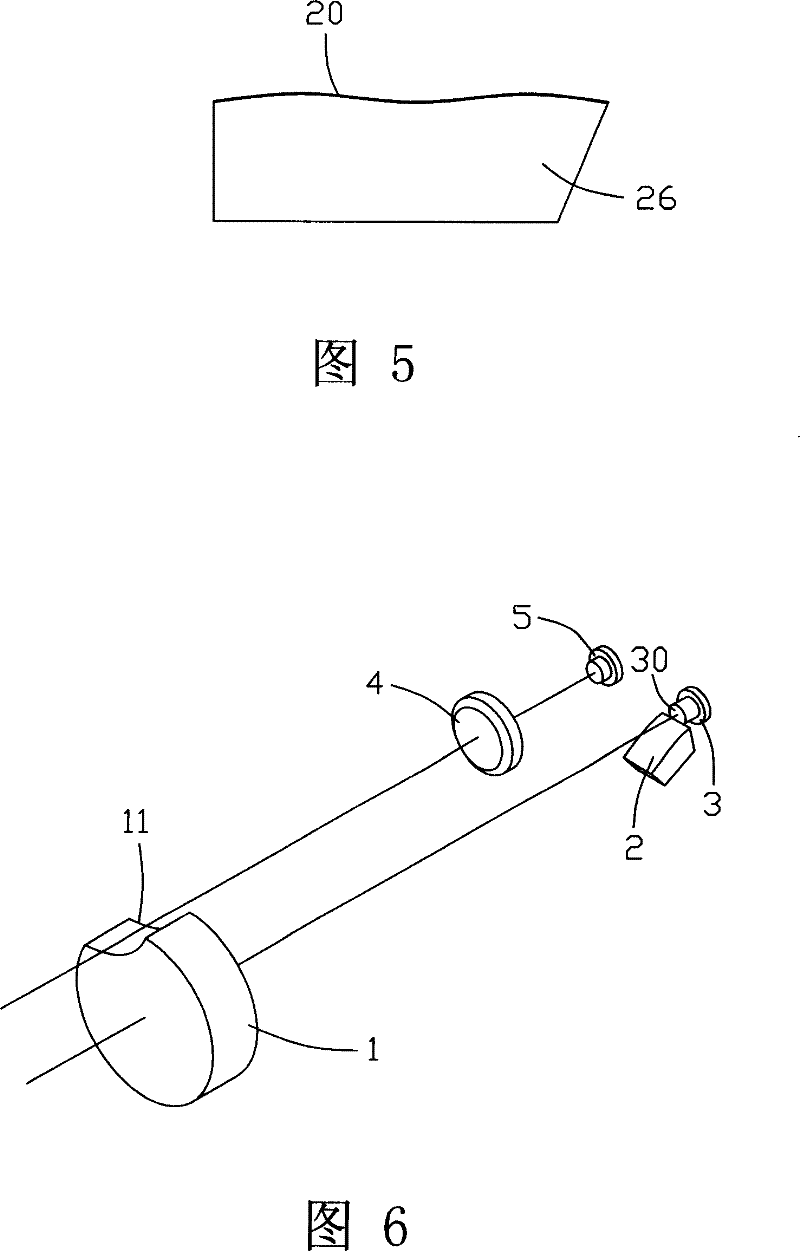

[0023] The detailed description and technical content of the laser ruler optical system of the present invention are now described as follows in conjunction with the accompanying drawings:

[0024] see Figure 6 , the optical system of the laser ruler of the present invention is an optical system for measuring the distance of an object to be measured, which includes a laser light source 5, a lens assembly 4 at the transmitting end, a lens assembly 1 at the receiving end, and a curved reflective assembly with a reflective curved surface 20 2 and a light receiving component 3 having a light receiving surface 30.

[0025] Such as figure 1 , figure 2 and image 3 shown in figure 1 The middle is to show the optical path diagram when the laser ruler of the present invention is used to measure a long-distance target, and figure 2 Then display a light path diagram when measuring a short-distance target, image 3 and figure 2 similar, but showing figure 2 The view formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com