High-density fiber distribution frame

a fiber distribution frame and high-density technology, applied in the field of high-density fiber distribution frames, can solve the problems of unsatisfactory or excessive fiber optic cable displacement, bending and other forces, and prior art products that require substantial fiber displacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]With reference now to the several drawing figures in which identical elements are numbered identically throughout, a description of the preferred embodiment of the invention will now be provided.

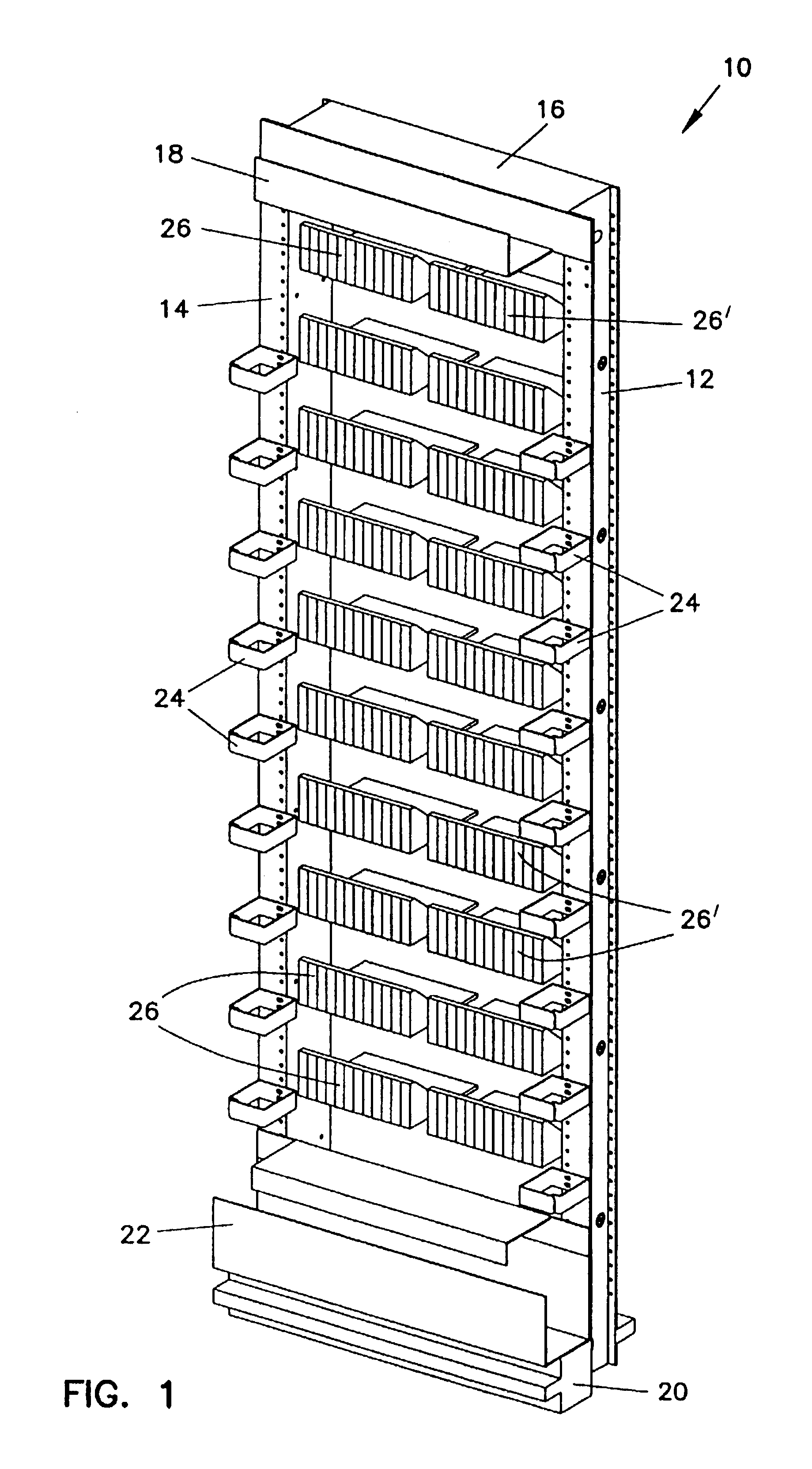

[0043]With initial reference to FIG. 1, a fiber distribution frame 10 is shown. The frame 10 includes spaced-apart side walls 12,14 connected at their upper ends by a top wall 16. Connected to the forward side of the top wall 16 is a trough 18 for carrying cables and the like as is conventional. The bottom of the frame 10 is provided with a pedestal 20 which also has secured to it a trough 22 for carrying cables and the like. The forward edges of the side walls 12,14 are provided with a plurality of clips 24 for holding fiber optic cables extending vertically in front of side walls 12,14.

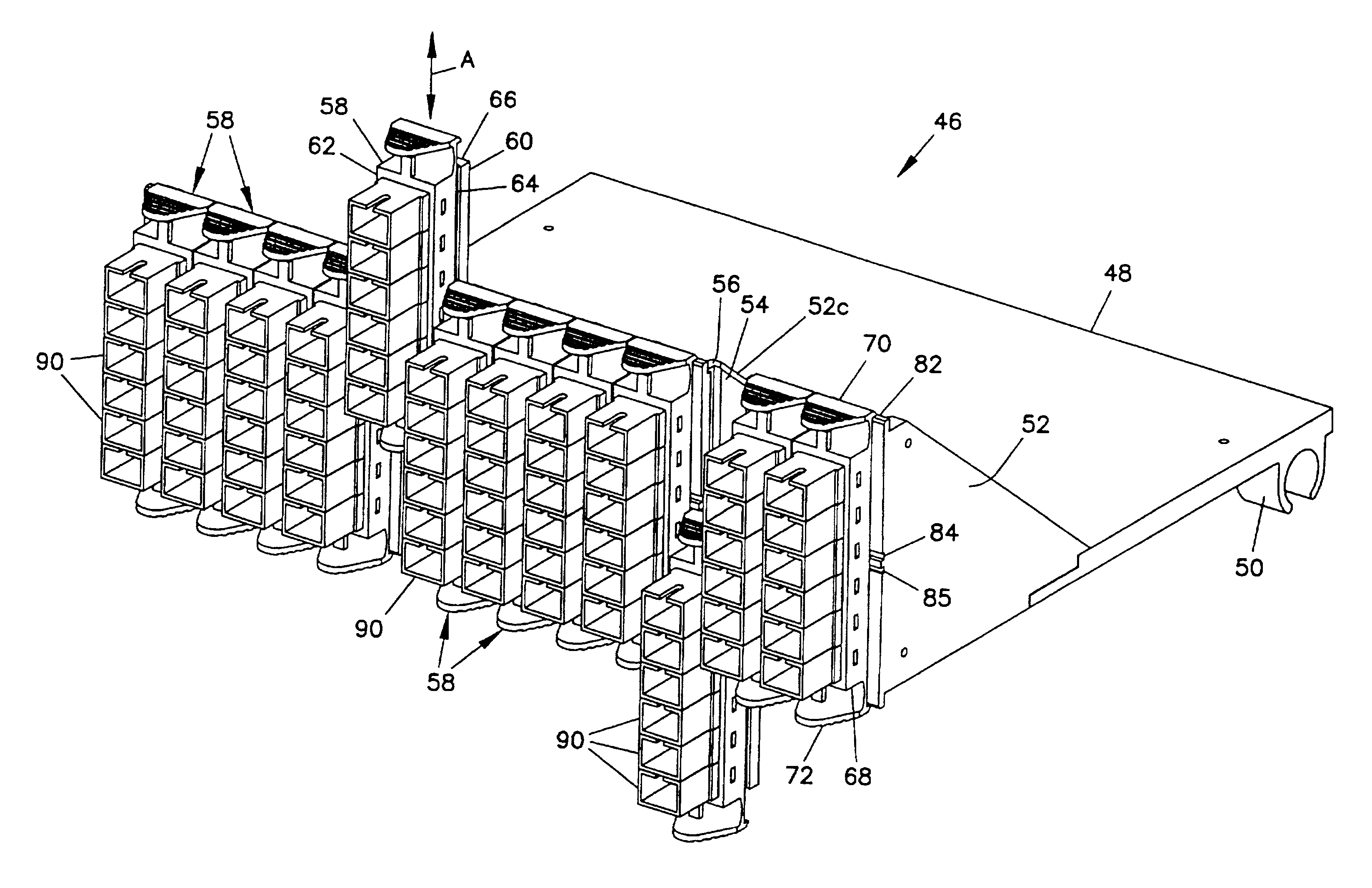

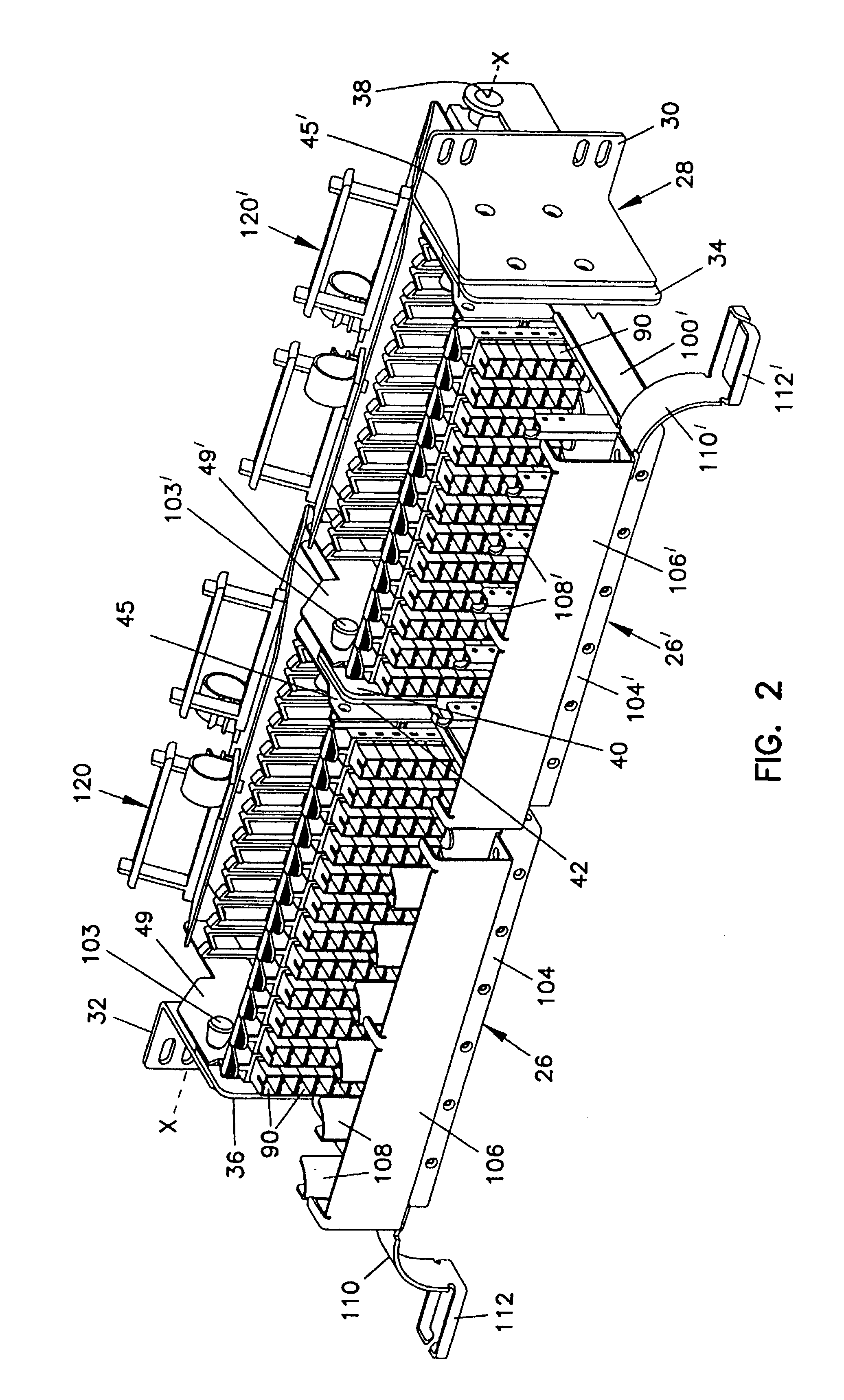

[0044]Contained within frame 10 between side walls 12,14 are a plurality of left and right mounting fixtures 26,26′ (schematically shown in FIG. 1). A detailed description of mounting fixtures 26,26′ i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com