Filtering apparatus and filter element

a filter element and filtering technology, applied in the field of filtering apparatus, can solve the problems of high production cost, unintentional off of the filter element, and less known solution, and achieve the effects of low production cost, simple structure design, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

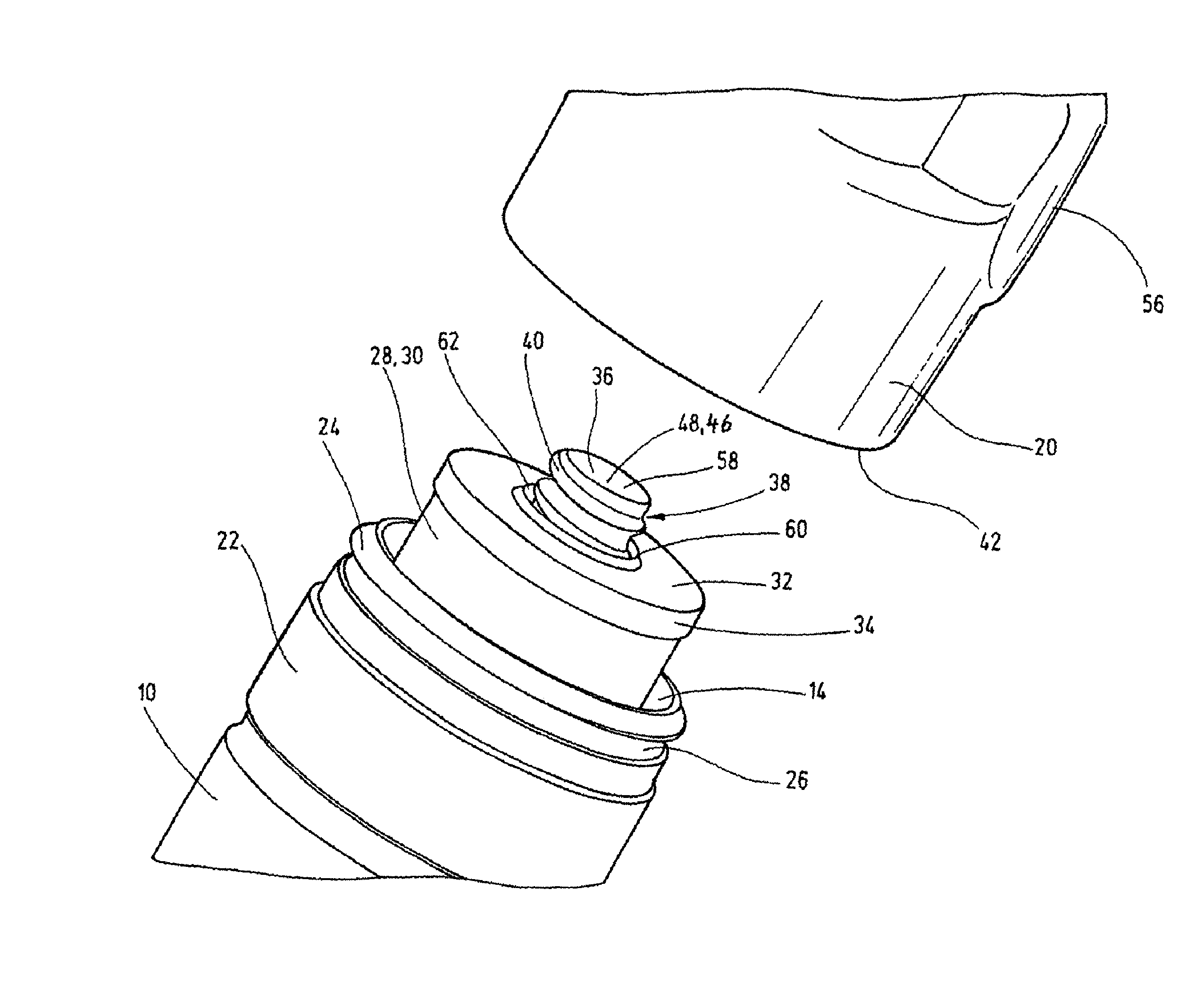

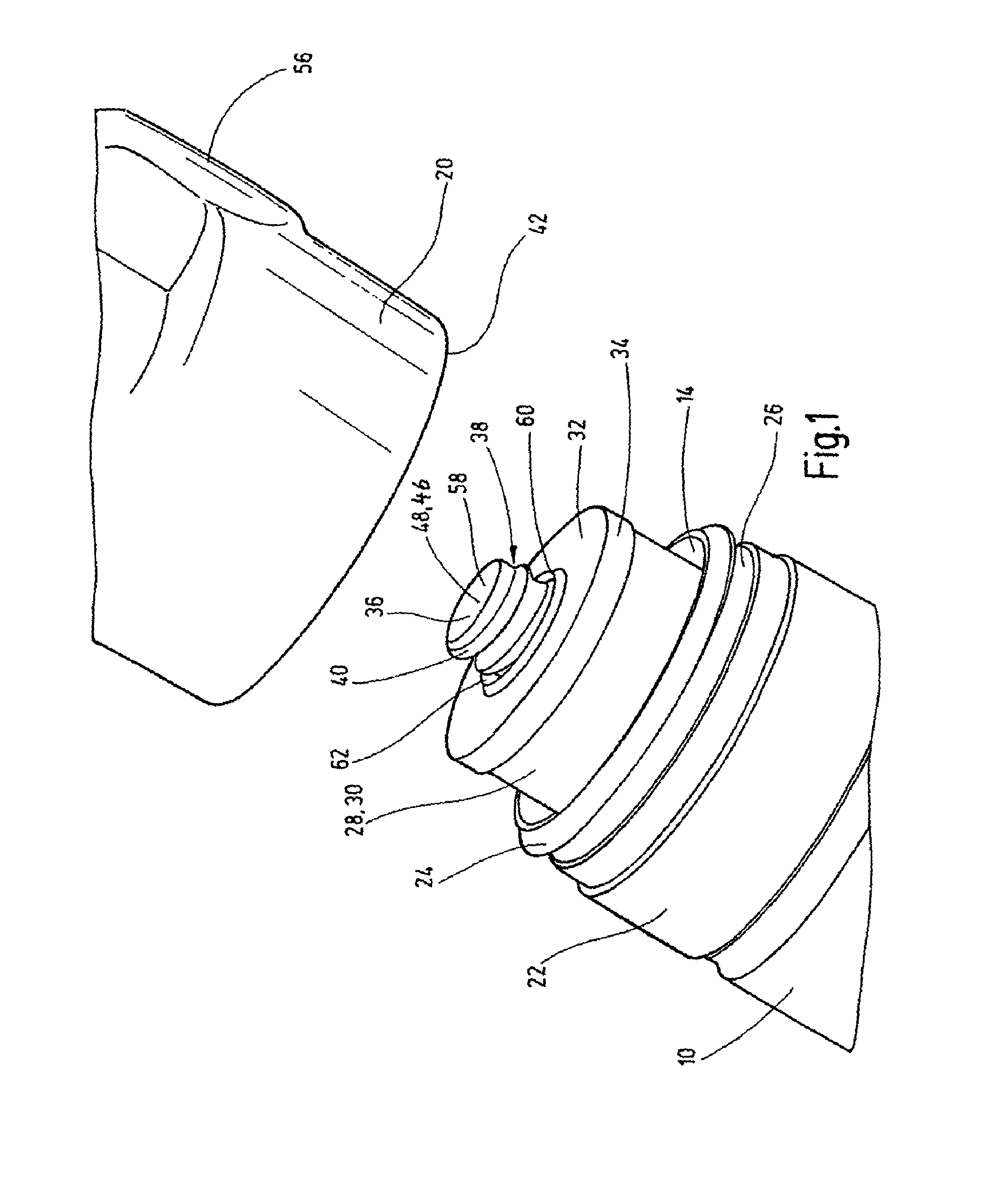

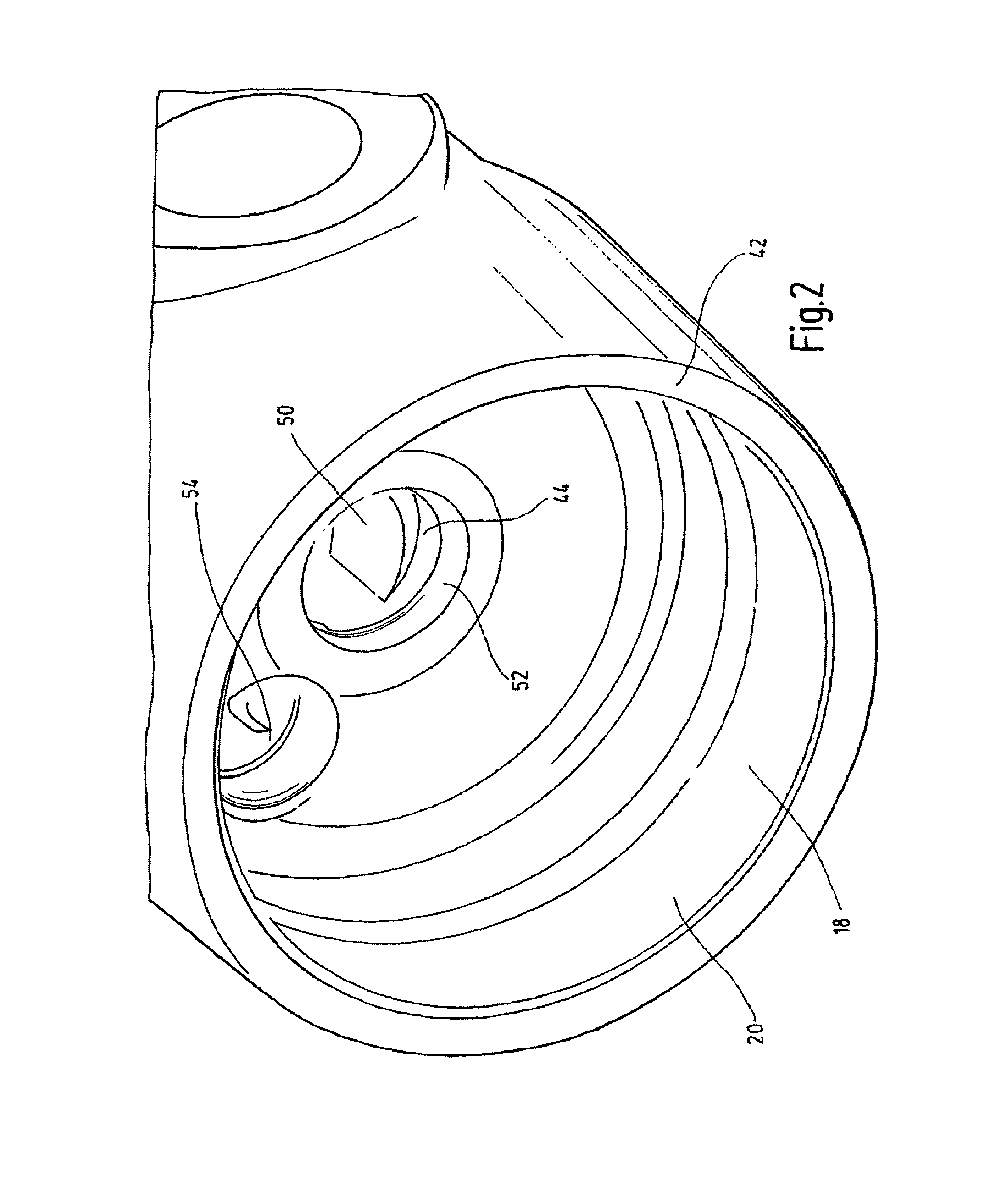

[0018]A filter housing 10 is in the form or shape of a cup rotationally symmetrical in its outline to the longitudinal axis 12, and has one open top end 14 and a closed bottom (not shown). On the top end 14, a peripheral catch groove 16 in the form of a snap connection can be engaged by a catch overlap of the cover part or housing cover 20 of the filter housing 10, when the cover part 20 is placed on the top end 14 of the filter housing 10 by a rotary or snap motion. This snap and catch connection for the housing cover 20 with the filter housing 10 is shown especially in FIG. 3. Alternatively, as shown in FIG. 1, instead of a catch groove 16, a peripheral elevation 22 can be provided with an external threaded segment (not shown) to screw on the housing cover 20 by an internal threaded segment (not shown). In both cases, as shown in FIG. 1, in the direction of the top end 14, a projecting, peripheral sealing lug 24 at the top borders a sealing channel 26 which can house a sealing mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| transition point | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com