Freeze-thaw resisting cement and its production process

A production method and anti-freeze-thaw technology, applied in the field of anti-freeze-thaw cement and its production, can solve the problems of anti-freeze-thaw technology, building erosion and peeling, unsatisfactory effect, etc., to achieve self-leveling and uniformity Good performance, fast setting and hardening, good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention will be described in detail in combination with the company’s trial firing production:

[0033] This embodiment is carried out under the conditions of general cement production equipment. Except for the process measures described below, the processes not mentioned are carried out according to the ordinary cement production process, which will not be repeated in this example.

[0034] Selection of raw materials and fuels:

[0035] Lime-based raw materials: stable quality, high quality, less impurities, CaO content greater than 50%.

[0036] Clay material: high freeze-thaw resistance cement to C 3 The content of A is more stringent, requiring the alkali content of clay raw materials (K 2 O+Na 2 O) Less than 1.0%.

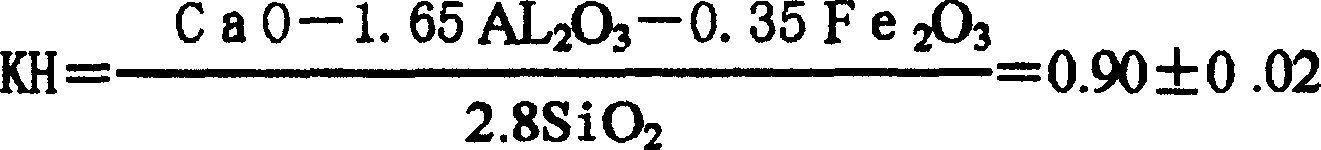

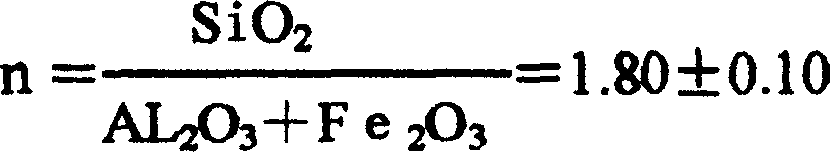

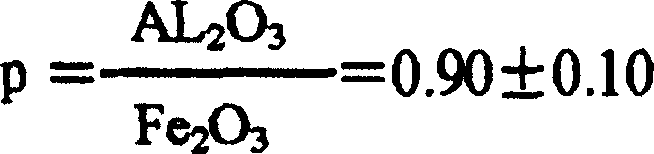

[0037] Iron raw materials, high-speed iron raw materials are required, Fe 2 O 3 The content is between 55.0%-62.0%. To produce high-resistance freeze-thaw building cement, the most important thing is to control AL in clinker 2 O 3 According to the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| curing time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com