Block brake

A brake and block type technology, applied in the direction of drum brakes, brake types, brake components, etc., to achieve the effect of simple structure and sensitive braking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation

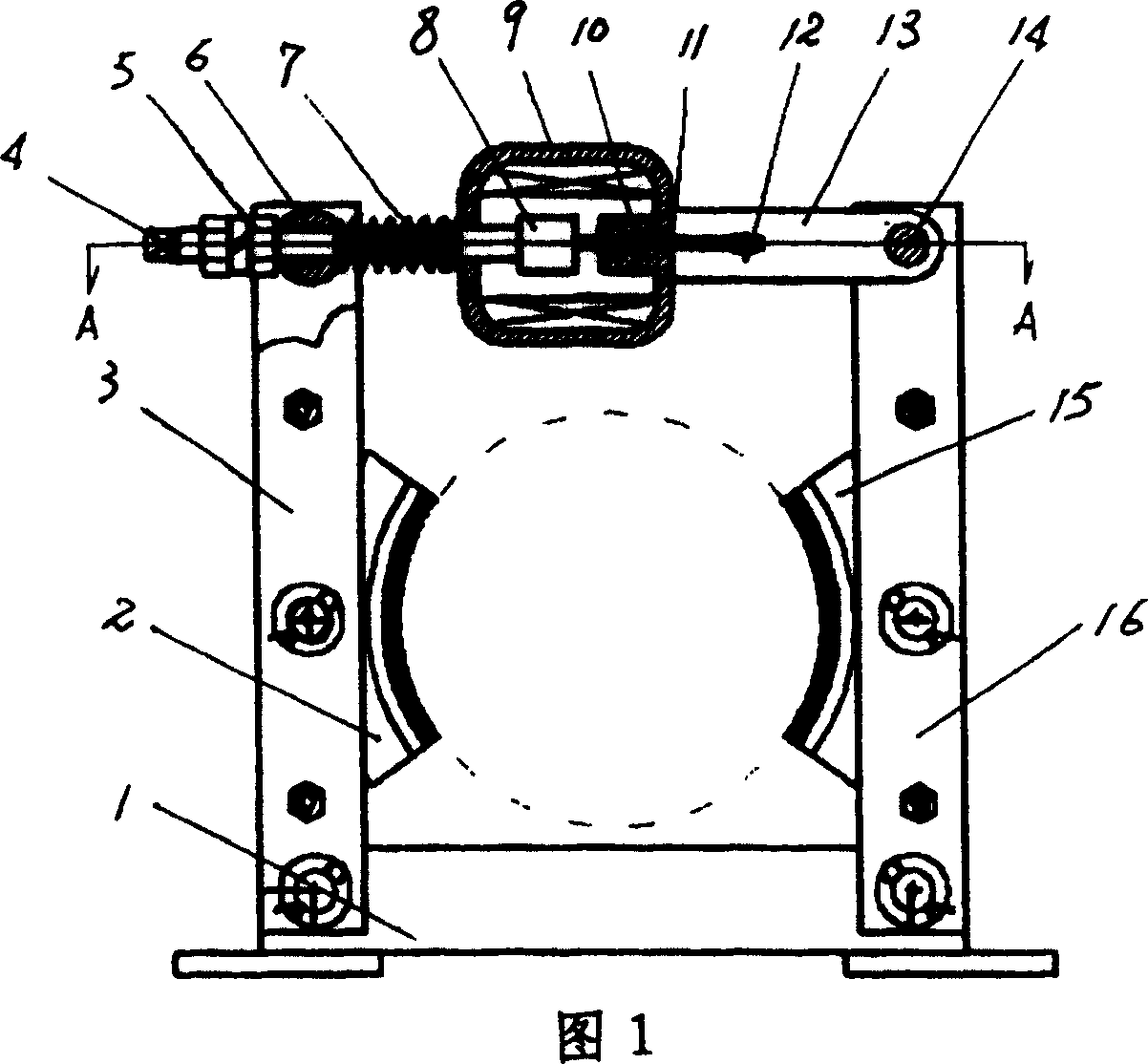

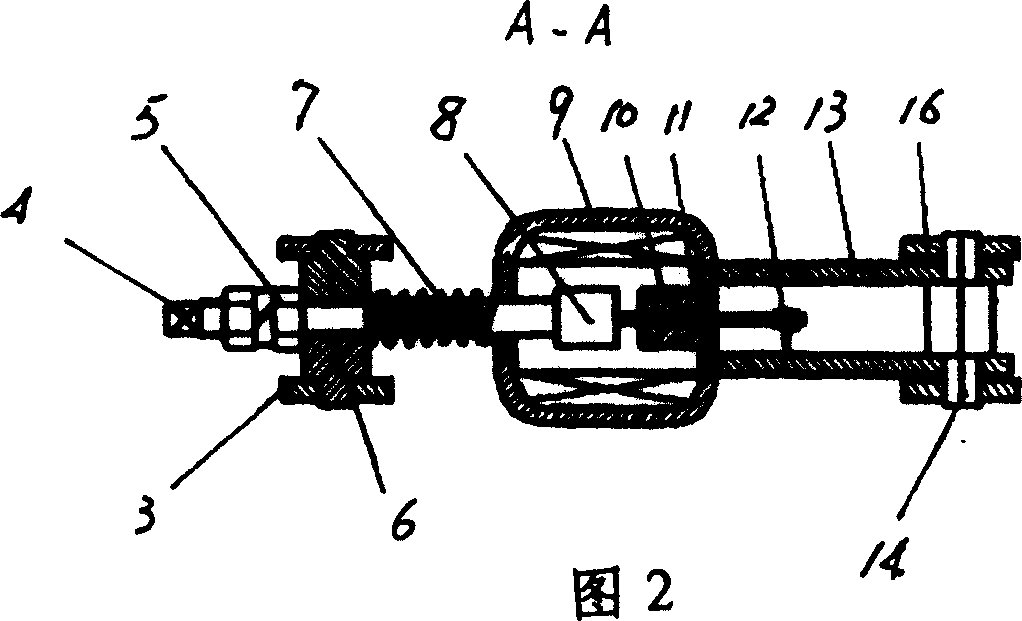

[0010] As can be seen from the embodiment shown in Figures 1 and 2, it includes a base 1, left and right brake arms 3, 16 respectively hinged to the base 1, a pair of brake shoes 2 respectively hinged to the left and right brake arms , 15, brake pull rod 4, brake electromagnet 9, brake release spring 7; brake pull rod 4 is directly connected with the armature 8 of brake electromagnet 9; it is characterized in that brake pull rod 4 passes through left pin shaft 6 and left system The boom 3 is hinged, that is, the brake rod 4 passes through the hole of the left pin shaft 6 and is limited by the nut 5 threadedly connected with the brake rod 4 on the left side of the left pin shaft 6; the brake release spring 7 is set on the left pin shaft 6 and the brake rod 4 between the housing of the brake electromagnet 9; the brake electromagnet 9 is hinged with the right brake arm 16 through the right pin 14 through a pair of mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com