Method for reinforcing space concrete beam column node by sticking fiber cloth

A technology of beam-column joints and fiber cloth, which is applied to building structures, building materials, buildings, etc., can solve the problems of not being able to improve the performance of the entire joint, and achieve the effects of increased ductility, improved joint strength, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

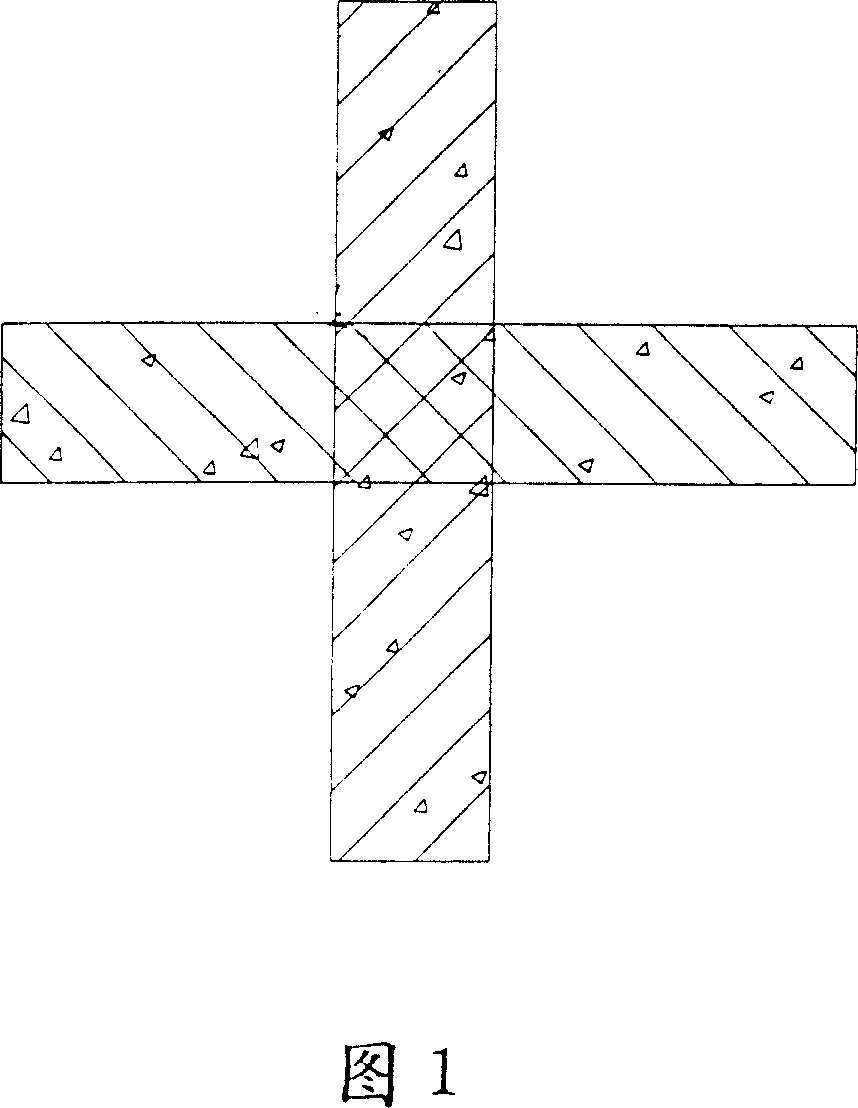

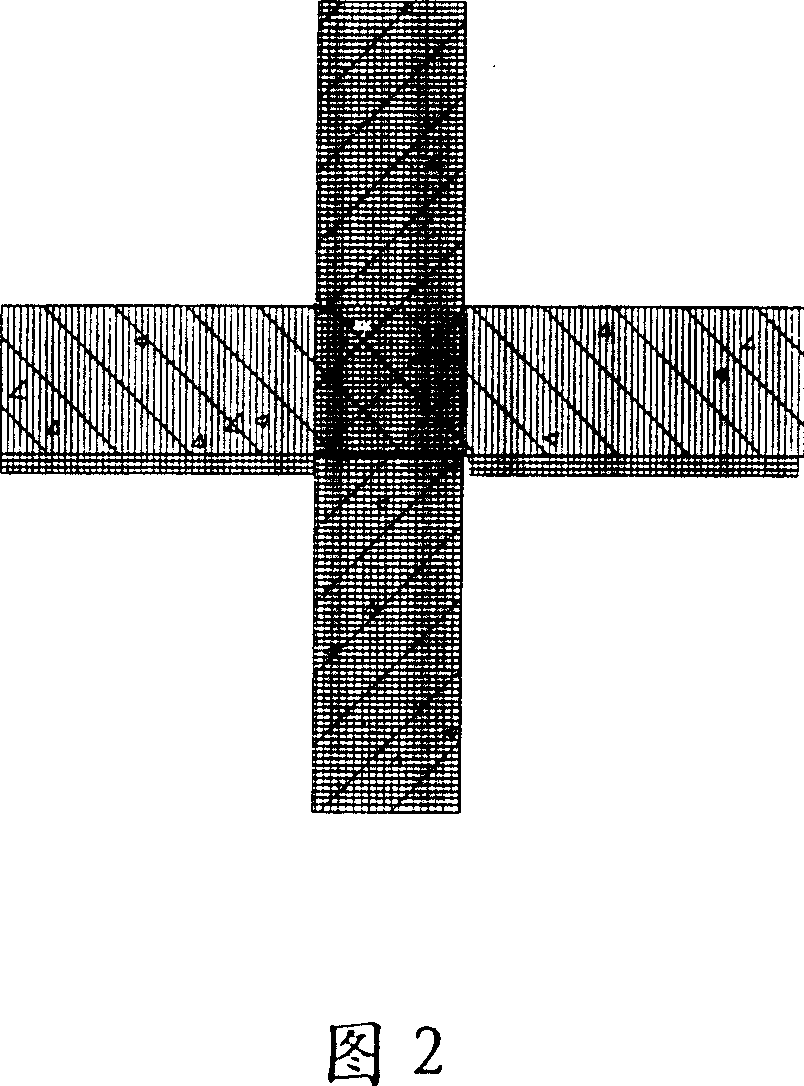

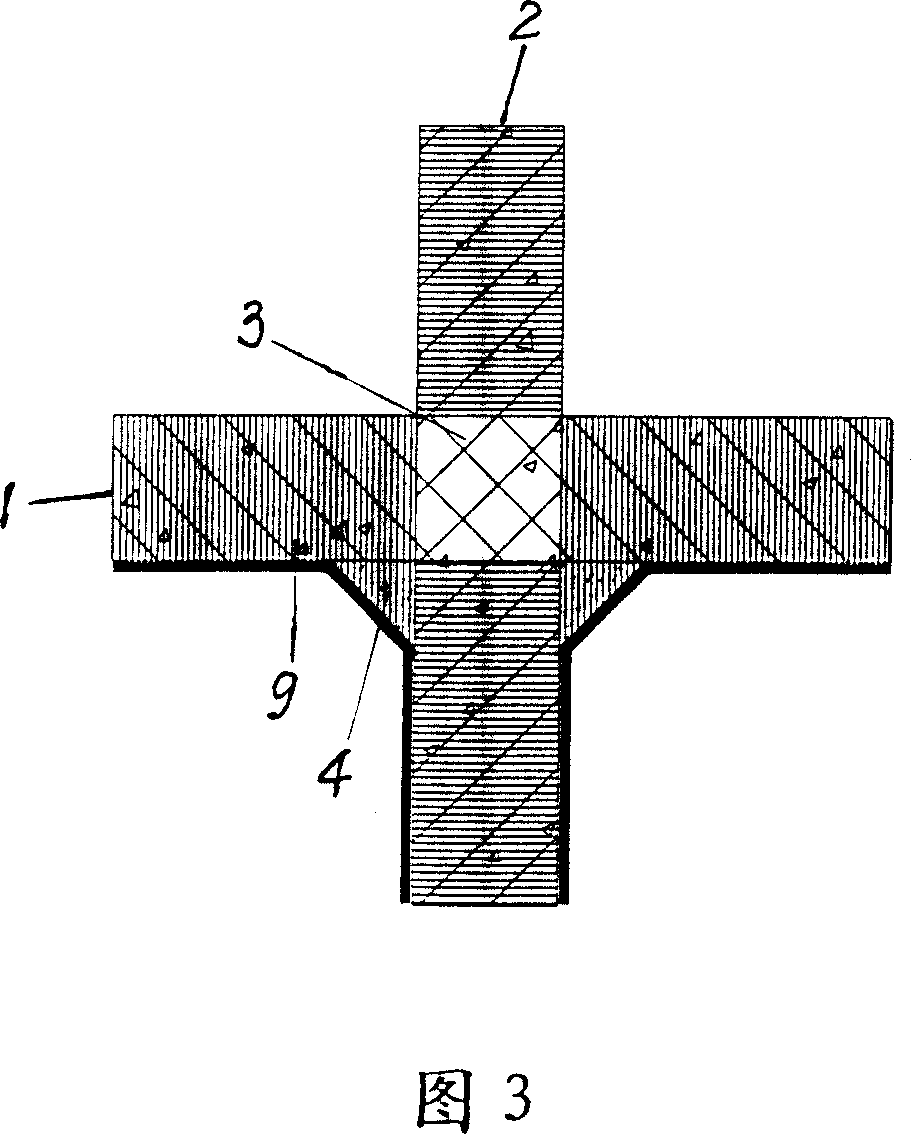

[0015] Referring to Fig. 3 and Fig. 4, according to the structure of pasting fiber cloth to reinforce space concrete beam-column joints of the present invention, firstly, plain concrete is added to the bottom of the beam around the core area 3 of the intersection area of beam 1 and column 2, that is, concrete is added to form a triangular shape. Concrete blocks4. As shown in Figure 3, the triangular concrete block 4 can be arranged on two sides of the plane. As shown in Figure 4, the triangular concrete blocks 4 can be arranged on two or four sides of the solid.

[0016] Then paste the fiber cloth on the surface of the triangular concrete block 4 and the beam 1 column 2, so that the concrete block and the node main body are connected together. Paste the fiber cloth 9 at the beam end and the column end at last.

[0017] Adopting the beam-column node structure of the present invention, as required, plain concrete can be added to the upper part of the beam around the core are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com