Thin film metal crystallizer casting machine and application method

A thin-film metal and mold technology, applied in the field of casting machines, can solve the problems of advanced casting production that cannot be used for thin-film metal molds, achieve the effect of easy and convenient man-machine dialogue and improve the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

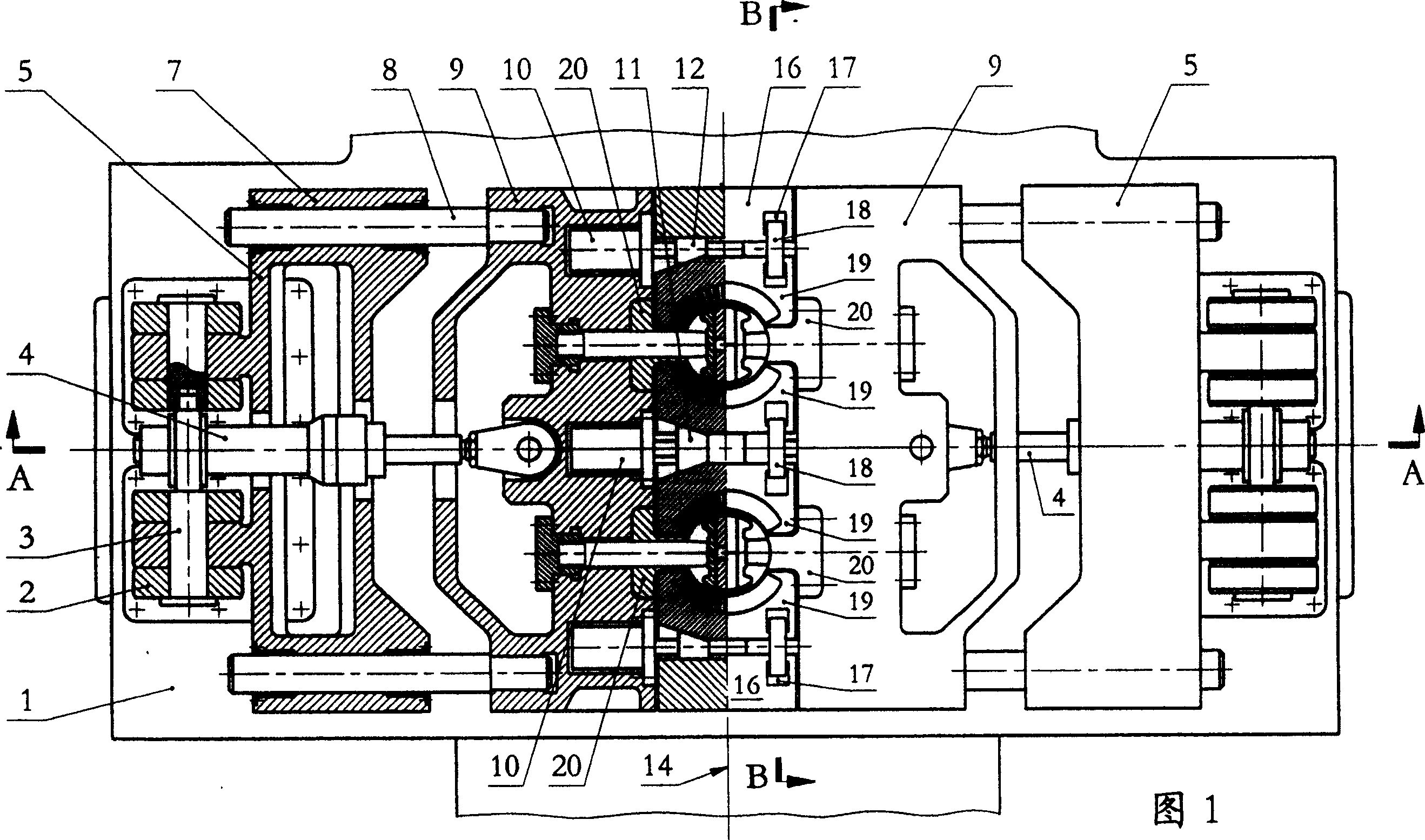

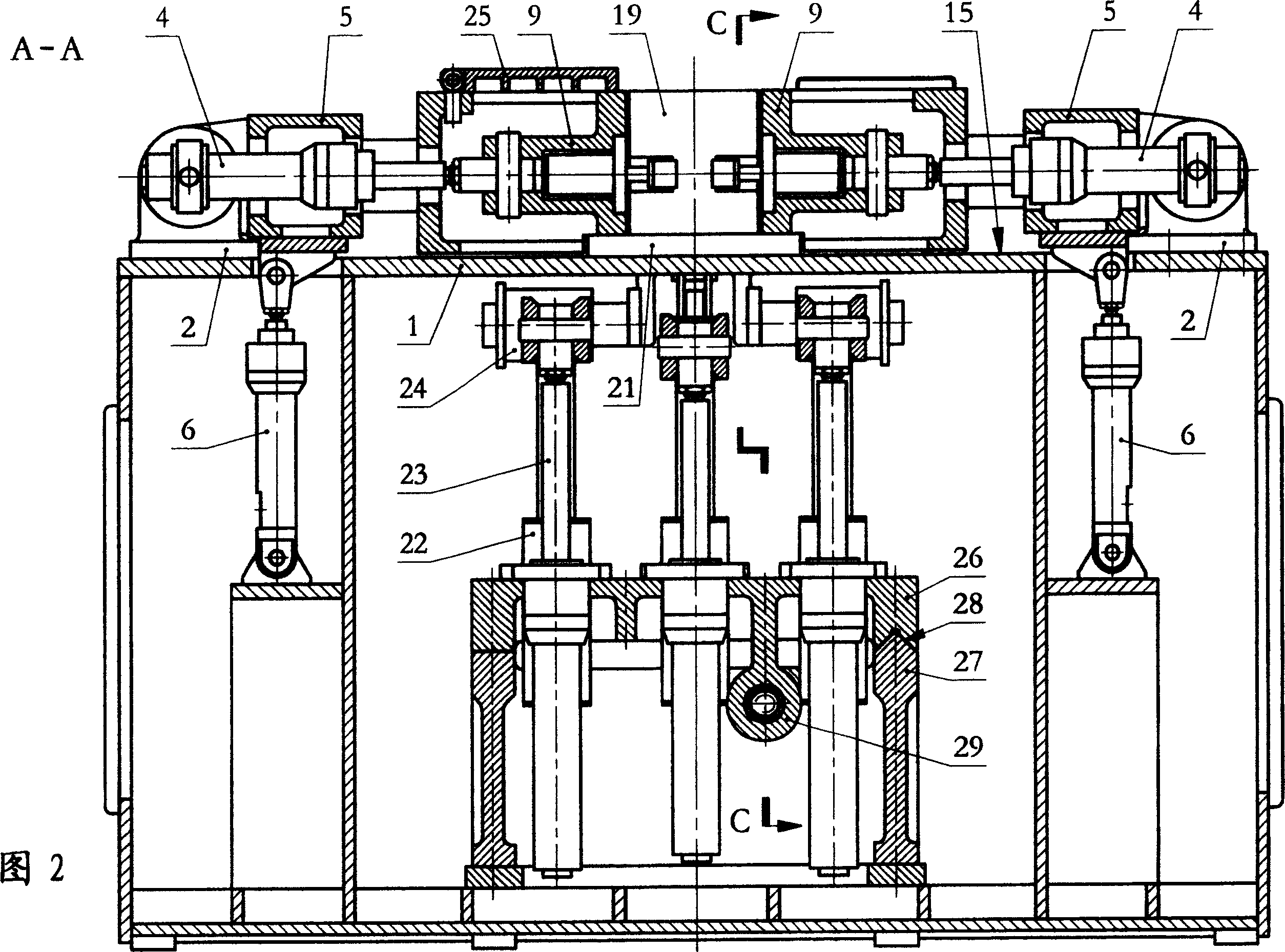

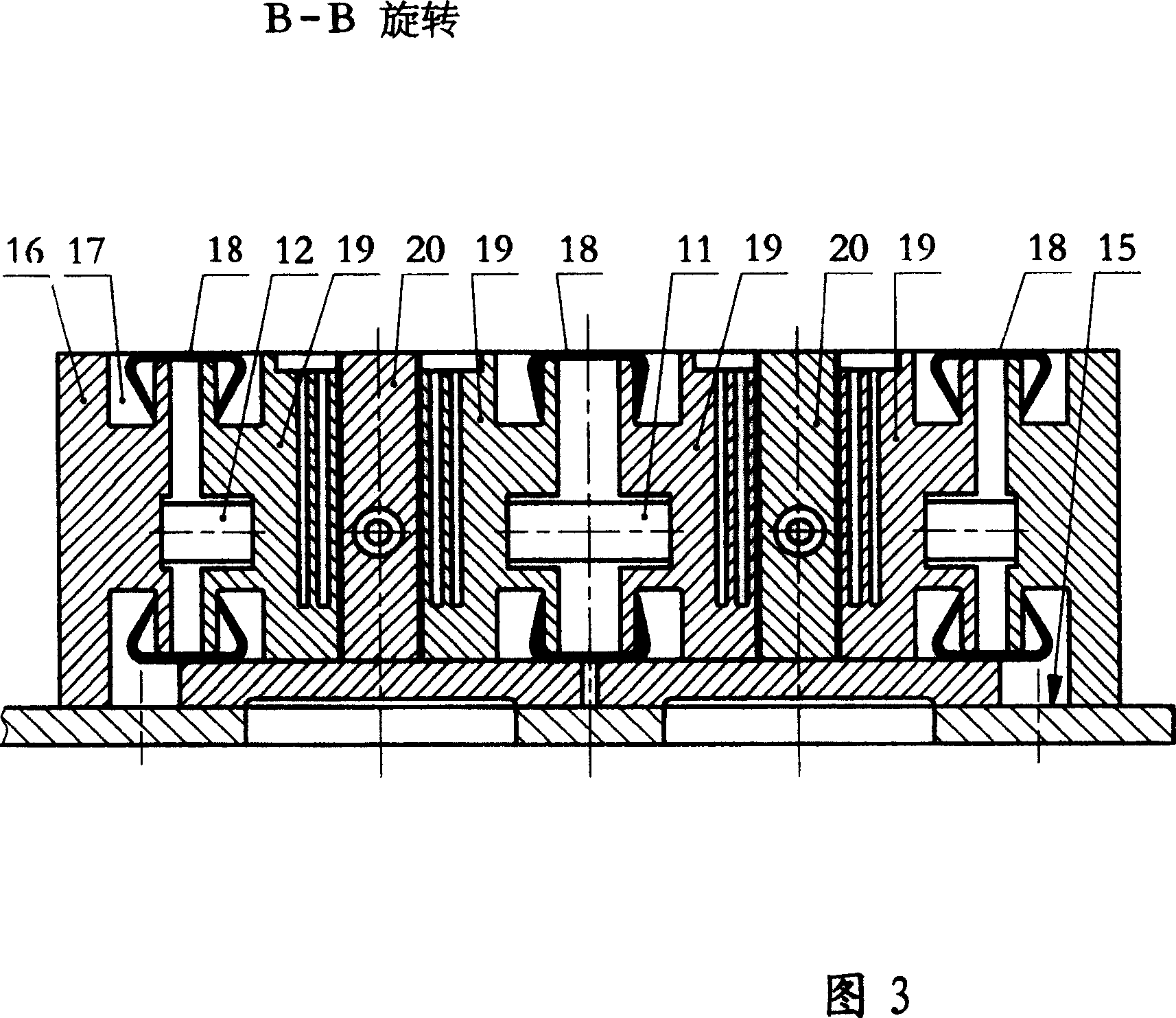

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] This embodiment is a casting machine with double casting positions. The double casting position structure is very beneficial for making full use of the functions of each component, obtaining a balanced force system structure, and optimizing the overall performance. However, the comparison between the double casting position and the single casting position is only the present invention. As for the translocation reproduction of the features, this embodiment only describes one of them and covers all of them.

[0036] As shown in Figures 1, 2 and 6, the structure of the present invention is formed by installing various components inside and outside the frame of a shell structure and the bed. The upper surface of the bed is called the bed surface. The bed surface of this embodiment is an integral plane. If the bed is designed in a modular manner and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com