A fixture and method for seamlessly polymerizing plexiglass discs and flat plates

A technology of plexiglass and tooling fixture, applied in the field of plexiglass polymerization, can solve the problems of large shrinkage and collapse stress, residual, inability to adjust well, etc., and achieve the effect of strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

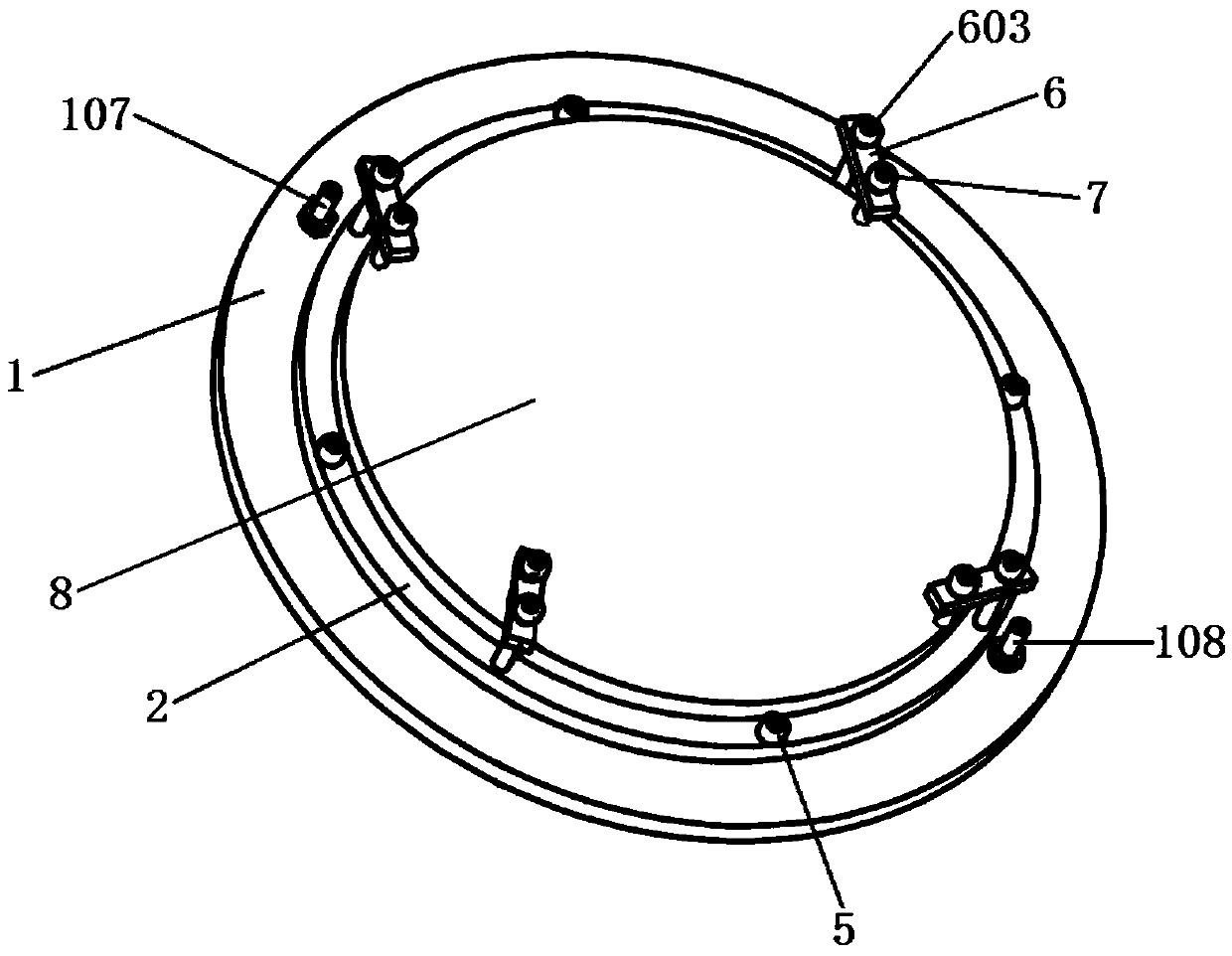

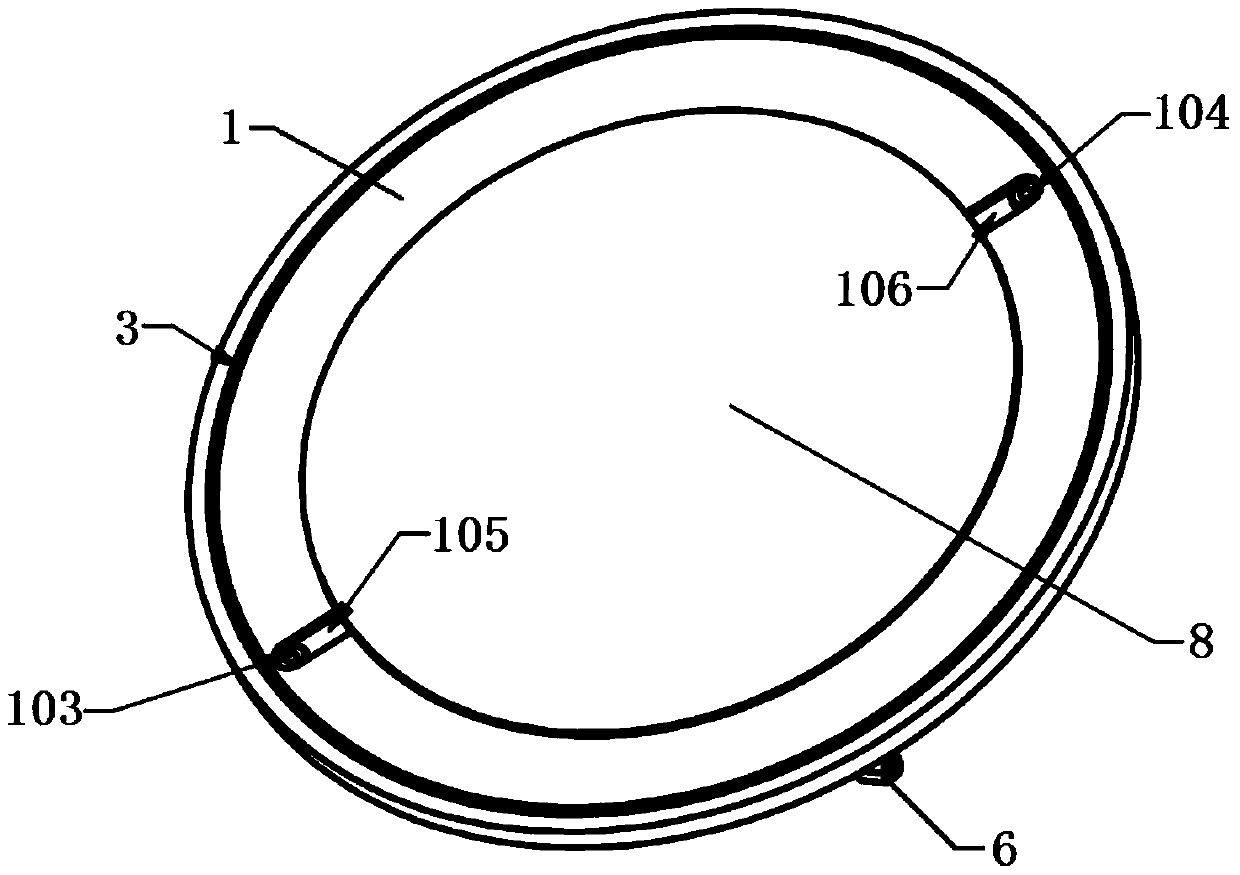

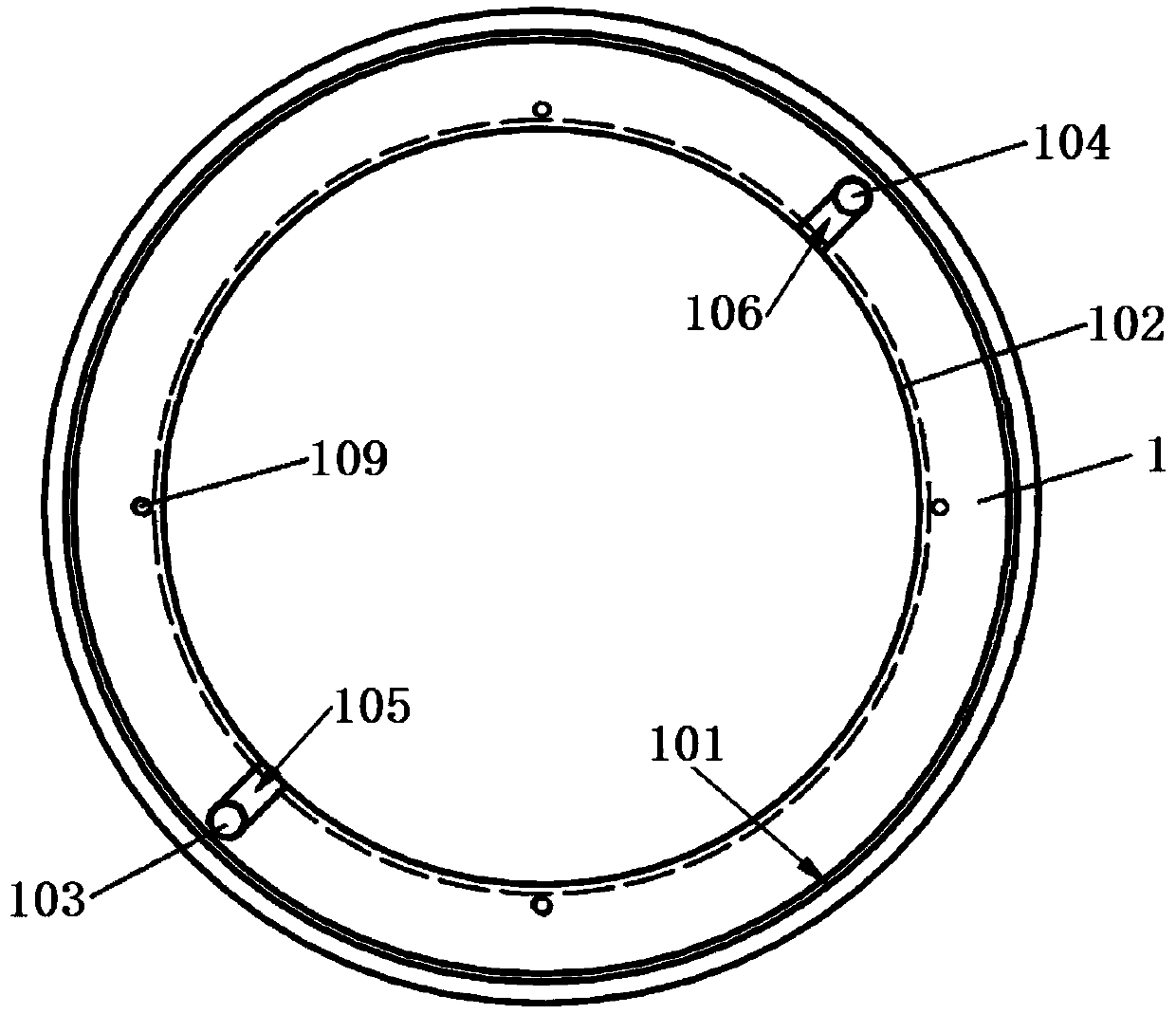

[0033] Such as Figure 1-7 Shown is a preferred embodiment of the invention.

[0034] A tooling fixture for a seamless polymeric plexiglass disc and a flat plate, comprising a ring-shaped lower pressure ring 1 and an upper pressure ring 2, the lower pressure ring 1 includes a first O-ring groove 101, a second O-ring groove 102, the air inlet 103, the air outlet 104, the glue inlet channel 105 and the glue outlet channel 106, wherein the first O-ring groove 101, the glue inlet channel 105 and the glue outlet channel 106 are arranged on the lower side of the lower pressure ring 1. The end of the glue channel 105 communicates with the air inlet 103, the end of the glue outlet channel 106 communicates with the air outlet 104, the air inlet 103 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com