LED display module based on jet dispensing and processing technology thereof

A technology for display modules and processing technology, which is applied in the direction of printed circuits, printed circuits, and electrical components connected to non-printed electrical components. Cost, ease of use, and material cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] see Figure 1-8 As shown, this embodiment is a processing technology of LED display module based on jet dispensing, including the following steps:

[0066] Step 1: The connector 2 makes ohmic contact with the through hole of the PCB board 1 by riveting or welding, so as to realize the circuit connection between the connector 2 and the PCB board 1;

[0067] Step 2: Put the PCB board 1 equipped with the connector 2 into the ultrasonic cleaning equipment, and the cleaning time is 12 minutes;

[0068] Step 3: Firstly, the solder paste is evenly bonded to both ends of the pads of the LED chip 3 area on the PCB 1 by dispensing or printing process, and then the LED chip 3 is bound to the solder paste position through the die-bonding equipment, so that the LED The pad of chip 3 is bonded to the pad of PCB board 1 through solder paste;

[0069] Step 4: After passing through the reflow oven with 8 temperature zones, the solder paste on the PCB board 1 bonded with the LED chip 3...

Embodiment 2

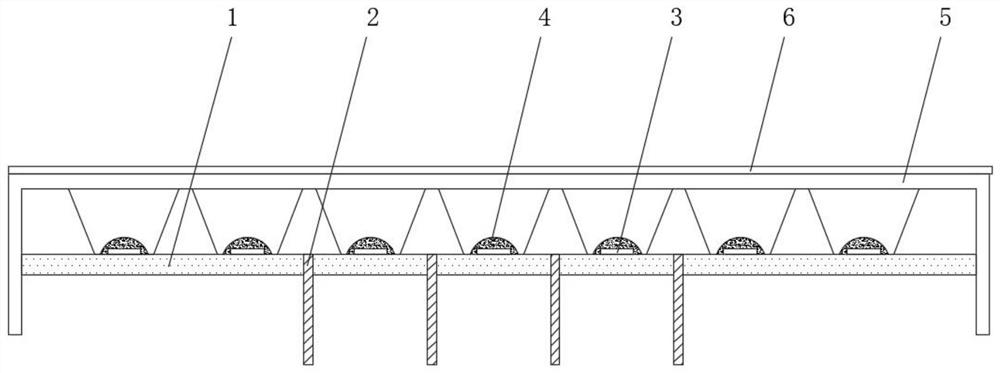

[0084] see figure 1As shown, this embodiment is a LED display module based on jet dispensing, including a PCB board 1, a connector 2, an LED chip 3, glue 4, a plastic reflective cover 5 and a panel 6, and the bottom of the PCB board 1 is connected with a connection A device 2, several LED chips 3 are installed on the top of the PCB board 1, the LED chips 3 are covered with glue 4, a plastic reflective cover 5 is installed on the top of the PCB board 1, and the LED chips 3 are located in the inner cavity of the plastic reflective cover 5, A panel 6 is installed on the top of the plastic reflective cover 5 .

Embodiment 3

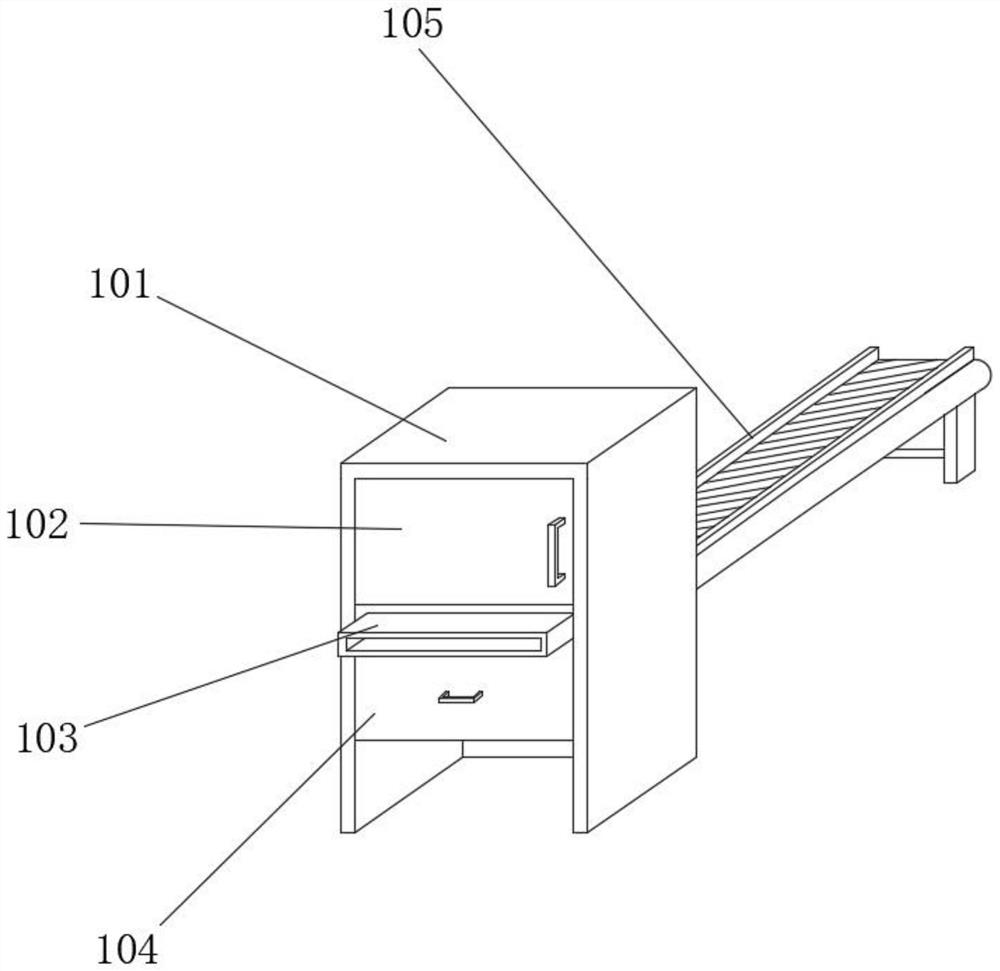

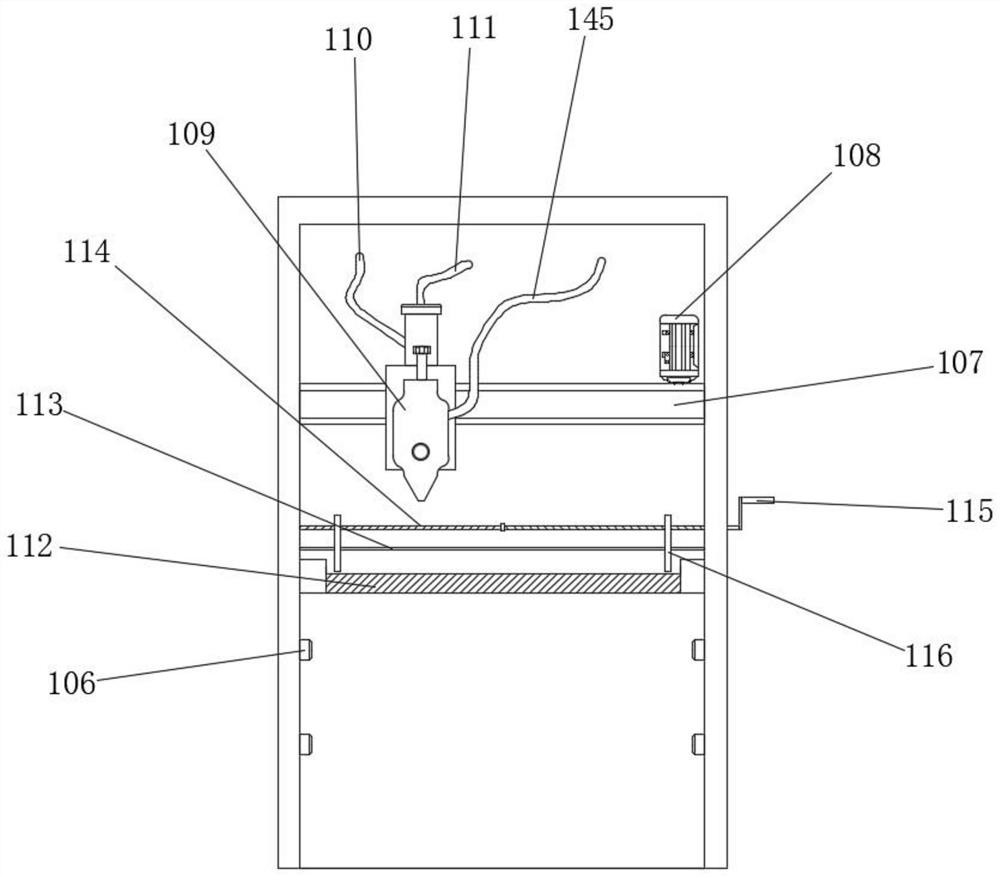

[0086] see Figure 2-8 As shown, the present embodiment is a jet dispensing device, including an installation box 101, a material inlet 103, a storage box 104, a first conveyor 105, a jet dispensing head 109, a second conveyor 112 and a mounting base 119, A sealing door 102 is installed on the top of one side of the installation box 101, a feed port 103 is installed in the middle of one side of the installation box 101, and a slideway 106 is installed on both sides of the bottom inner wall of the installation box 101, and a storage box is slidably installed on the slideway 106 104, handles are installed on the airtight door 102 and the storage box 104, the side of the installation box 101 away from the feed port 103 is connected to the first conveyor 105, and the top of the side of the installation box 101 close to the first conveyor 105 is installed with glue Material delivery pump 117, delivery air pump 118 and air extraction pump 144;

[0087] Mounting box 107 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com