Flywheel generating, multifunctional system and manufacturing method and important component included in this system

A technology for a power generation system and a power generation subsystem, which is applied to electromechanical devices, electrical components, and electric components, etc., can solve the problems of low output efficiency, single function, short energy storage period and power supply period, and the magnetic pole distribution of the flywheel rotor. Safety and high output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

[0045] (1) Referring to accompanying drawing 1, the system structure is shown in Fig. 1, and it is composed of: housing subsystem, flywheel, bearing subsystem, energy conversion and power generation subsystem. The three subsystems included in the flywheel system are the basic components included in the flywheel power generation system described in technical solution 1 of the present invention.

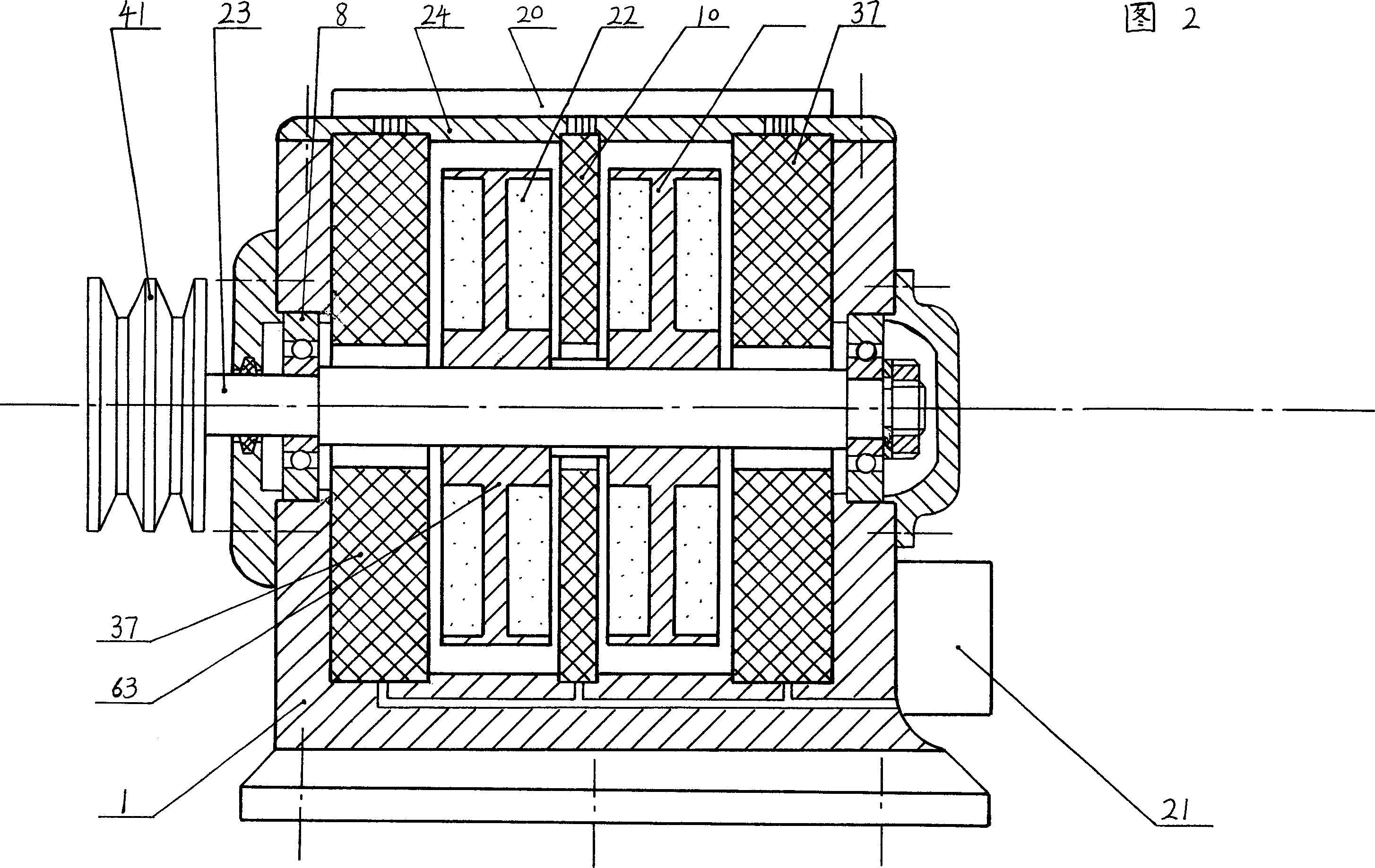

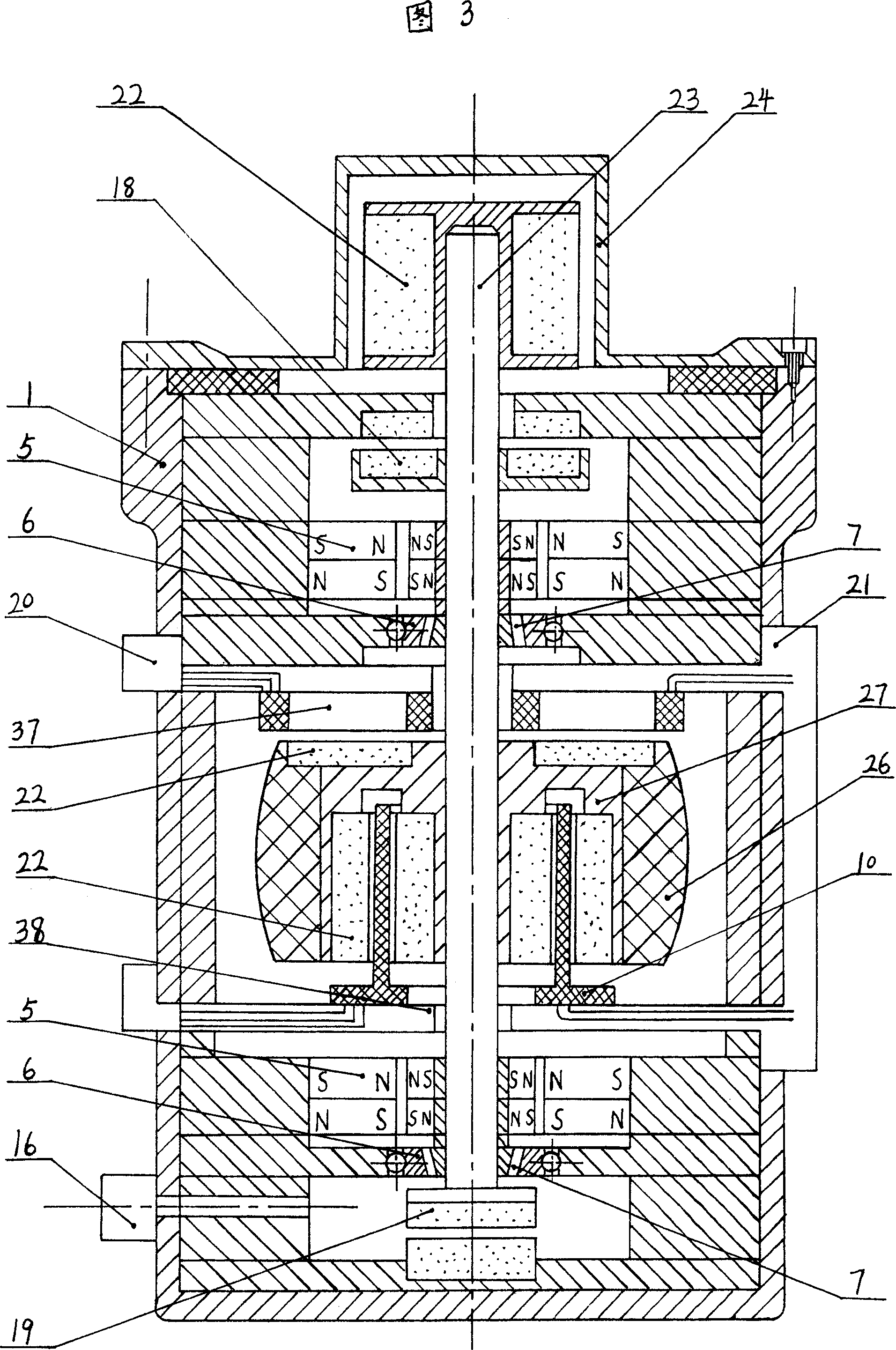

[0046] (2) The preferred embodiment of the first flywheel system, with reference to accompanying drawing 2, if divided by the three subsystems described in technical scheme 1: a housing 1, sealed electric input and output device 20, heat sink 21, sealed outer cover 24 belongs to the shell subsystem; a composite flywheel 63 (hereinafter referred to as composite flywheel) specially designed for "high magnetic permeability core winding" to expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com