CdS/Ti-MCM-41 loaded platinum photo catalyst and its preparation method

A technology of photocatalyst and catalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc. Effects of improved photocorrosion ability and improved hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

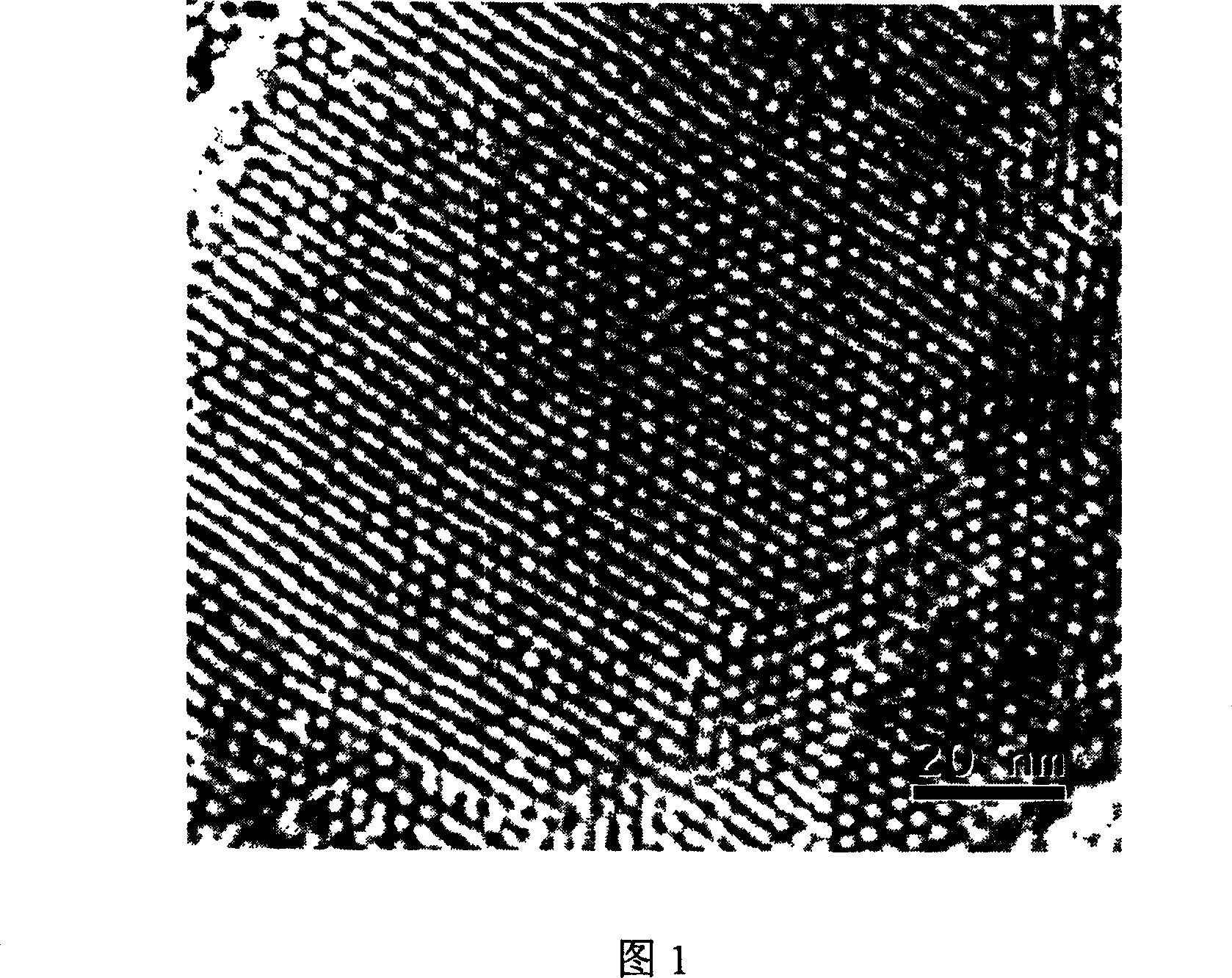

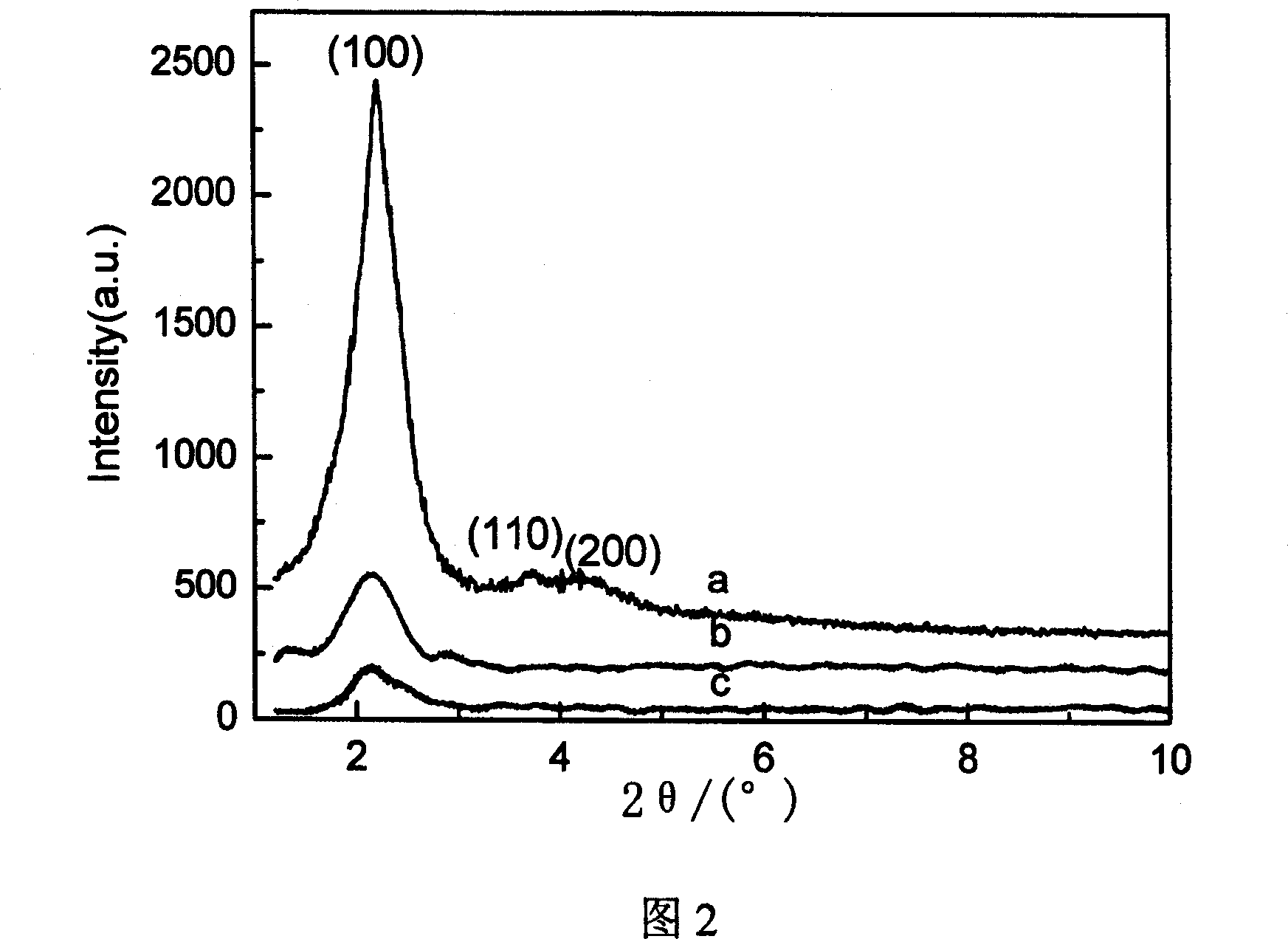

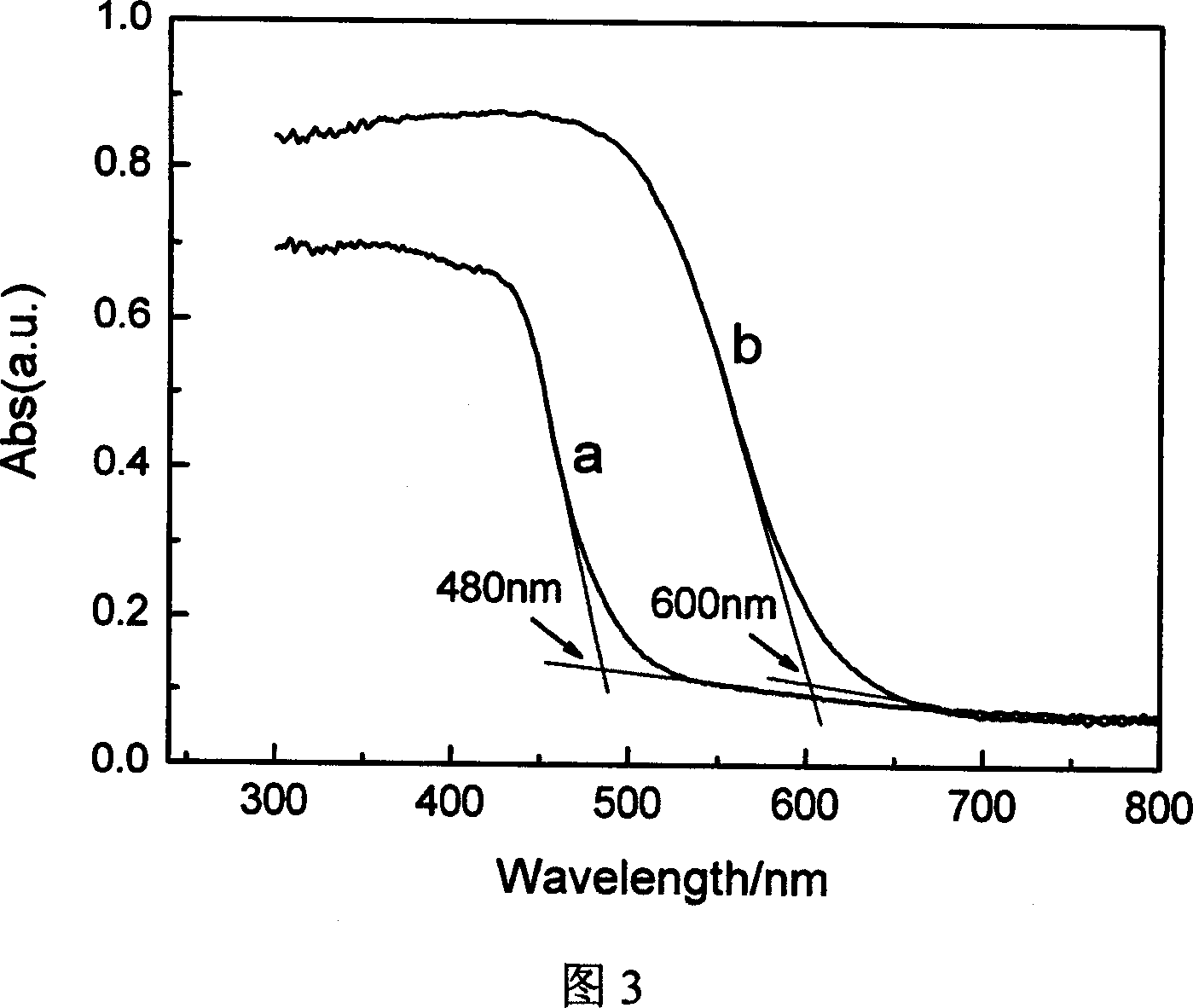

[0049] 1) In a water bath at 40°C, dissolve 0.36g of sodium hydroxide NaOH and 1.82g of cetyltrimethylammonium bromide CTAB in 45mL of deionized water, and slowly drop into 8.21mL of tetraethylorthosilicate with a pipette Ester TEOS, stirred at a speed of 800rpm to facilitate the hydrolysis of TEOS; 0.25g of tetrabutyl titanate TBOT was added dropwise after 0.5h, and the solution was transferred to a hydrothermal kettle with a Teflon liner after continuing to stir for 1h. Crystallized at 100°C for 72h. After the hydrothermal kettle was lowered to room temperature, the solution was filtered, repeatedly washed with deionized water and dried to obtain white raw powder CTAB / Ti-MCM-41;

[0050] 2) Calcining 2g of white raw powder CTAB / Ti-MCM-41 in air atmosphere at 500°C for 10h to remove template agent CTAB to obtain mesoporous matrix Ti-MCM-41;

[0051] 3) 1.25g cadmium acetate CdAc 2 Dissolve in 100mL methanol MeOH, add 1.0g CTAB / Ti-MCM-41 raw powder, and reflux at the boiling...

Embodiment 2

[0061] 1) In a water bath at 60°C, dissolve 0.72g of sodium hydroxide NaOH and 3.64g of cetyltrimethylammonium bromide CTAB in 90mL of deionized water, and slowly drop into 16.4mL of tetraethylorthosilicate with a pipette Ester TEOS, stirred at a speed of 500rpm to facilitate the hydrolysis of TEOS; 0.25g of tetrabutyl titanate TBOT was added dropwise after 1h, and after stirring for 1h, the solution was transferred to a hydrothermal kettle with a polytetrafluoroethylene liner and placed in Crystallized at 100°C for 72h. After the hydrothermal kettle was lowered to room temperature, the solution was filtered, repeatedly washed with deionized water and dried to obtain white raw powder CTAB / Ti-MCM-41;

[0062] 2) Calcining 2g of white raw powder CTAB / Ti-MCM-41 in air atmosphere at 500°C for 5h to remove template agent CTAB to obtain mesoporous matrix Ti-MCM-41;

[0063] 3) 1.25g cadmium acetate CdAc 2 Dissolve in 100mL methanol MeOH, add 1.0g CTAB / Ti-MCM-41 raw powder, and ref...

Embodiment 3

[0073] 1) In a water bath at 40°C, dissolve 0.72g of sodium hydroxide NaOH and 3.64g of cetyltrimethylammonium bromide CTAB in 90mL of deionized water, and slowly drop into 16.4mL of tetraethylorthosilicate with a pipette Ester TEOS, stirred at a speed of 800rpm to facilitate the hydrolysis of TEOS; 0.25g of tetrabutyl titanate TBOT was added dropwise after 1h, and after stirring for 1h, the solution was transferred to a hydrothermal kettle with a polytetrafluoroethylene liner and placed in Crystallized at 110°C for 48h. After the hydrothermal kettle was lowered to room temperature, the solution was filtered, repeatedly washed with deionized water and dried to obtain white raw powder CTAB / Ti-MCM-41;

[0074] 2) Calcining 2g of white raw powder CTAB / Ti-MCM-41 in air atmosphere at 600°C for 5h to remove template agent CTAB to obtain mesoporous matrix Ti-MCM-41;

[0075] 3) 2.5g cadmium acetate CdAc 2Dissolve in 200mL methanol MeOH, add 2.0g CTAB / Ti-MCM-41 raw powder, and reflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com