Flue gas stripping device

A stripper, flue gas technology, applied in chemical instruments and methods, petroleum industry, cracking, etc., can solve problems affecting service life, permanent distortion of heat transfer tubes, etc., to achieve reliable operation, lower operating temperature, and better results Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

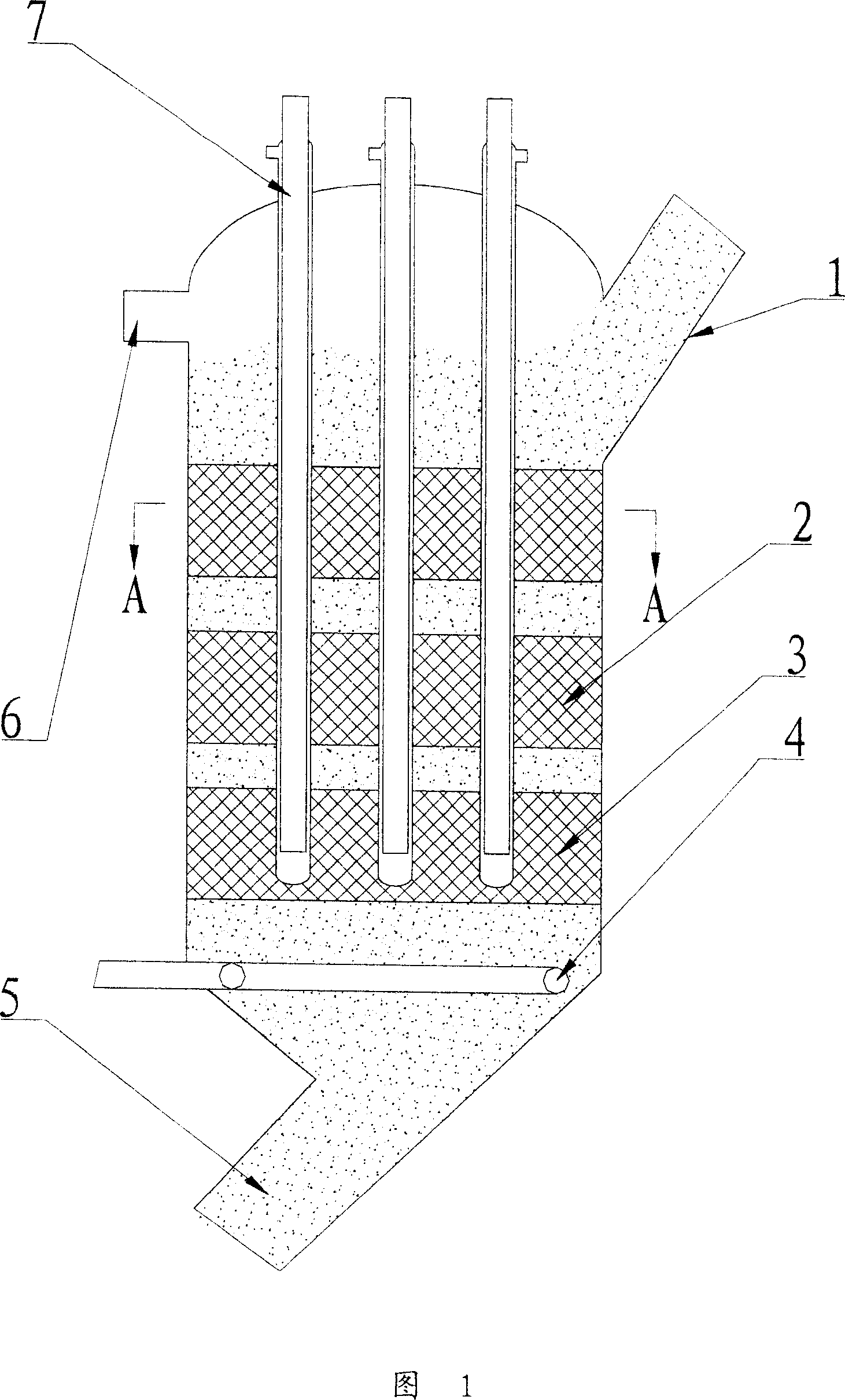

[0036] This embodiment illustrates: the beneficial effect brought by adopting the flue gas stripper of the present invention on the FCC device.

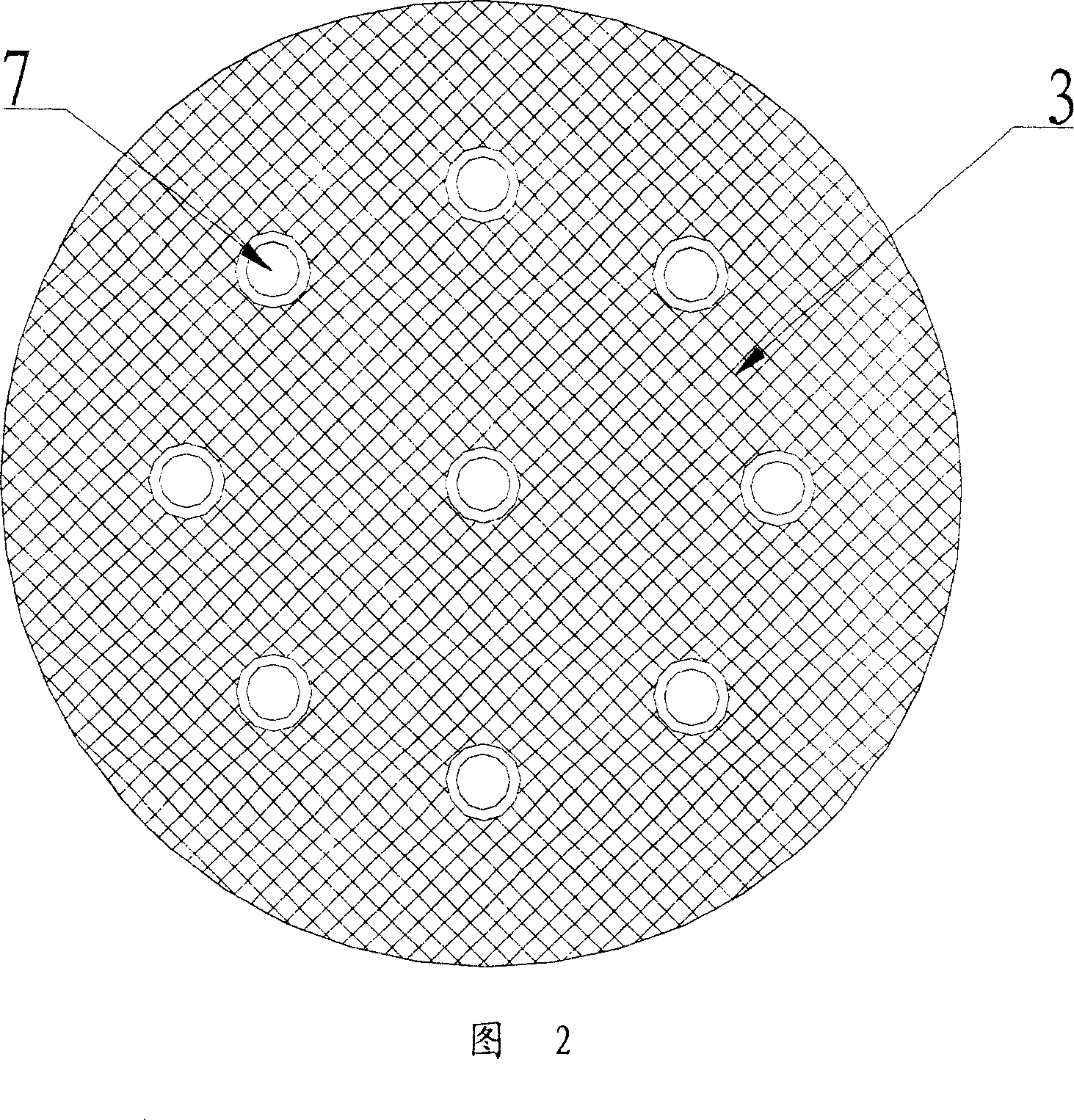

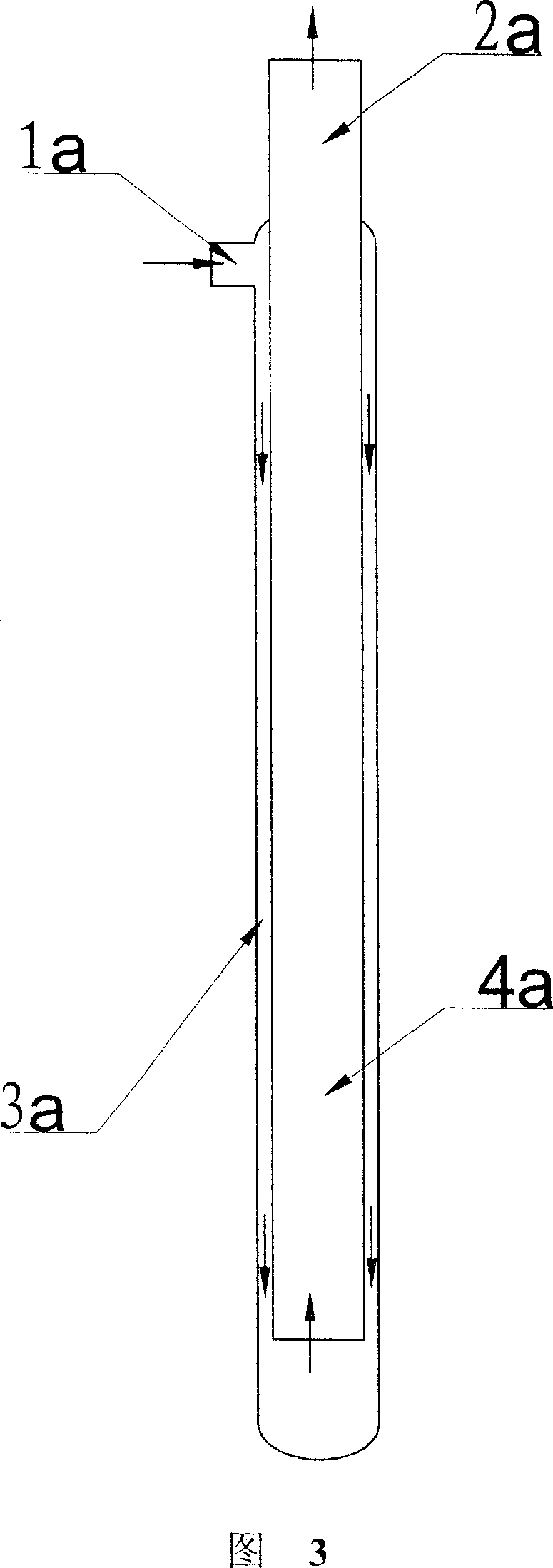

[0037] at a processing capacity of 100 x 10 4 Ton / year heavy oil catalytic cracking unit is transformed, and the flue gas stripper of the present invention is added. The flue gas stripper has a diameter of 2400mm and a height of 5650mm. It has three layers of internal components described in USP6224833, and the filler has a porosity of 75%. The stripper is equipped with a total of 20 nail heads to take heat pipes, the length of the heat pipes is 5.1m, and the heat transfer area of a single pipe is 5.6m 2 , with a total heat transfer area of 112m 2 , The heat load is 1.56×107W. Steam is used as the stripping medium, and the linear velocity of the stripping steam is 0.2m / s. After the industrial application test, the temperature of the dense-phase bed of the regenerator dropped from 705° to 698°, and the content of non-hydrocarb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com