Buttonhole machine

A sewing machine and buttonhole technology, applied to sewing machine components, sewing equipment, cloth pressing mechanism, etc., can solve problems such as warping, achieve light structure weight, reduce material consumption, and work quickly and accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

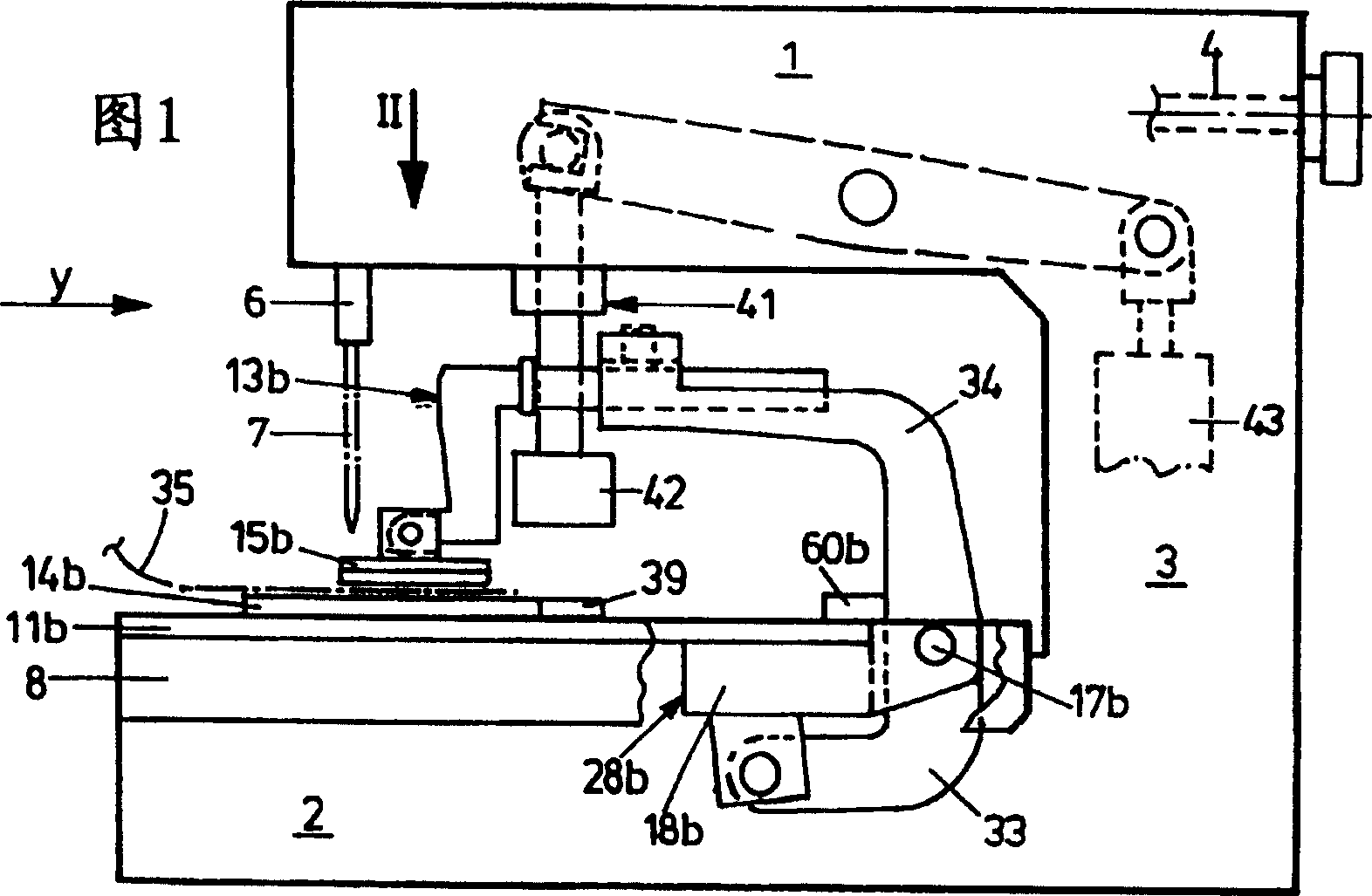

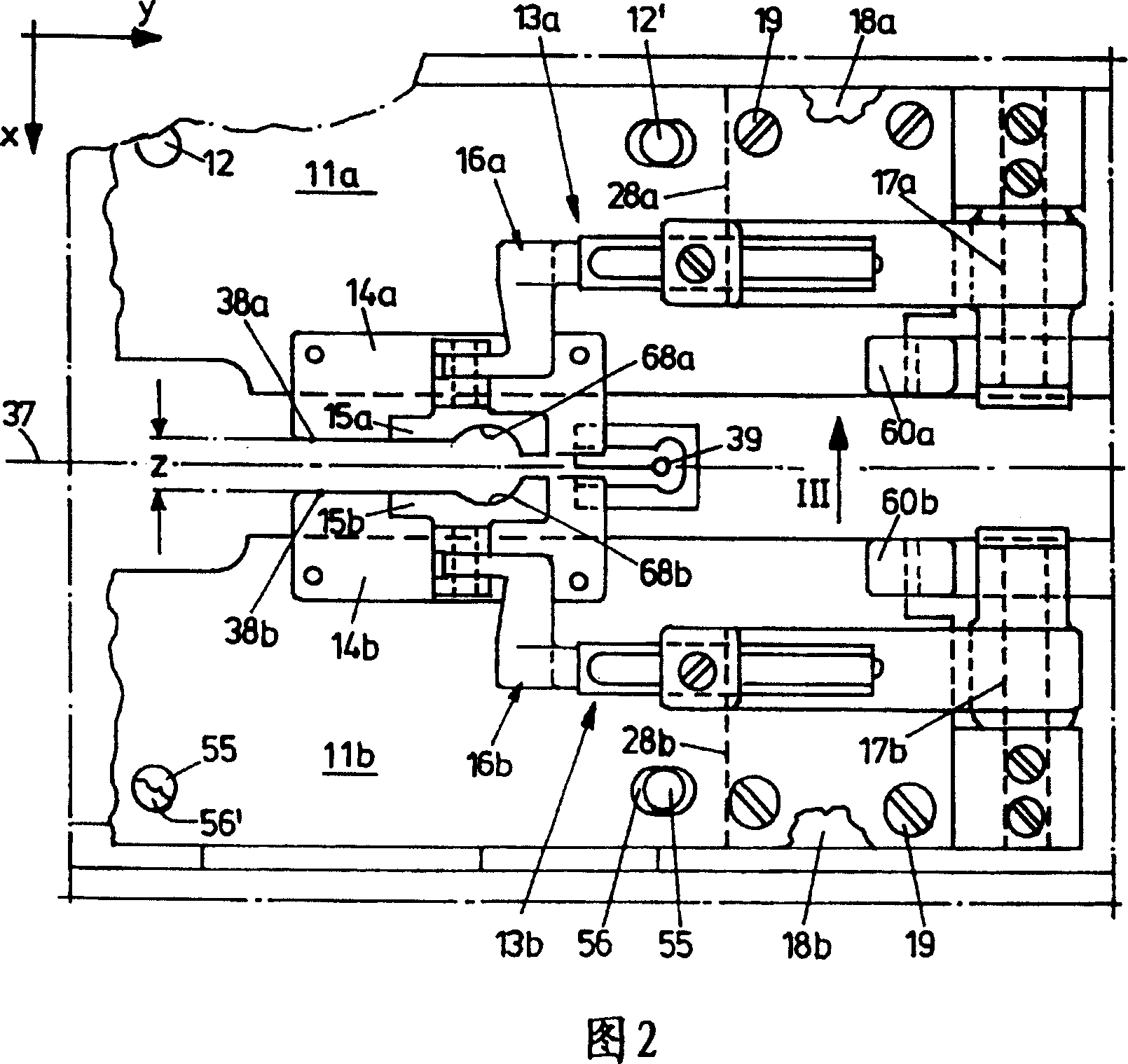

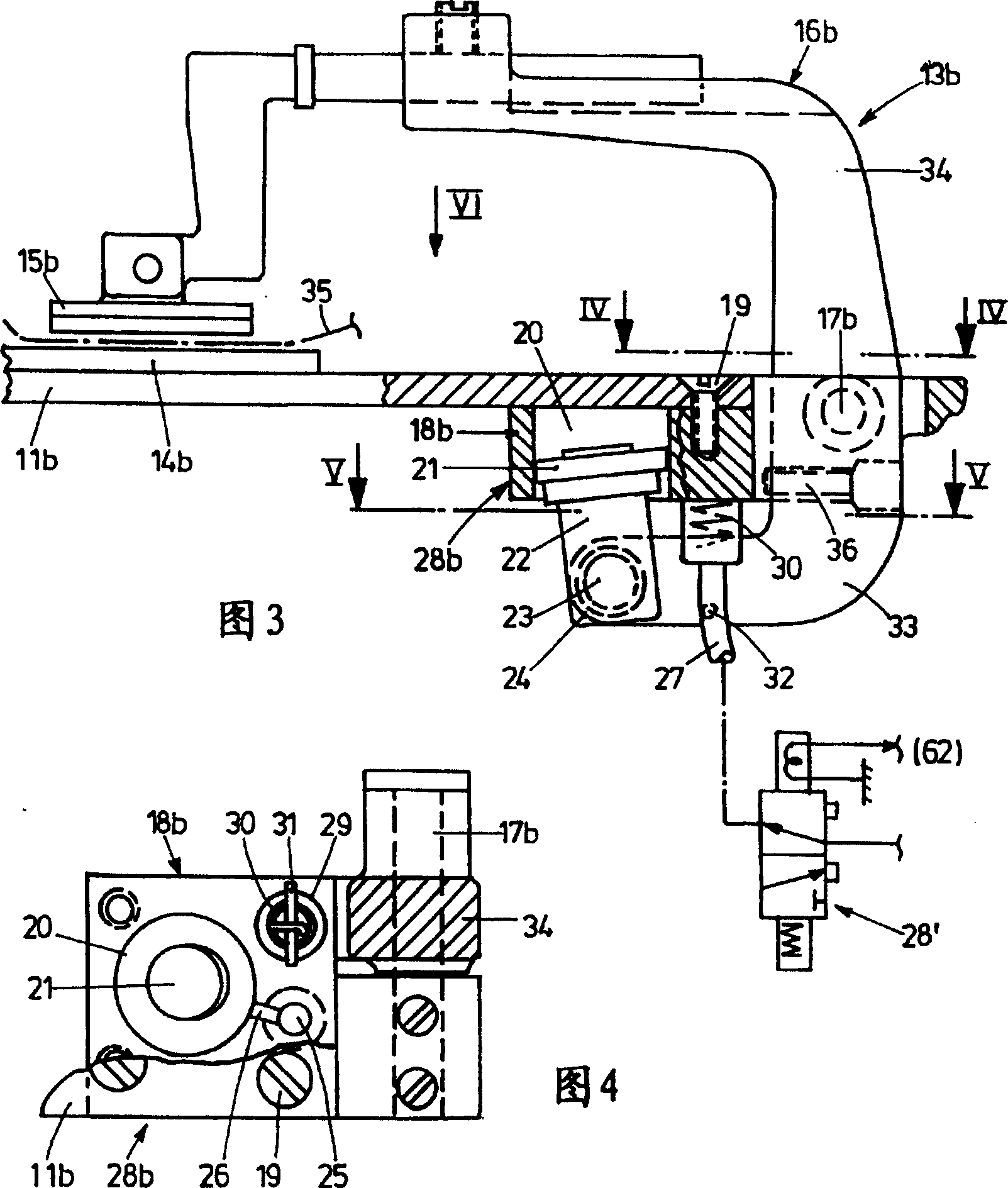

[0024] As shown in FIG. 1 , the buttonhole sewing machine is C-shaped, having a top arm 1 , a bottom base plate 2 in the form of a housing, and an approximately vertical bracket 3 connecting the top arm 1 and the bottom base plate 2 . The arm shaft 4 is generally supported in the arm 1; it can be driven by a motor 5, which is only schematically indicated in FIG. 8 . The actuation of the vertically movable needle bar 6 and the needle 7 as well as their jogging drive originate from the arm shaft 4 .

[0025] An x-y slide table 8 is arranged on the base plate 2, and the x-y slide table 8 is a cross slide, which can move in two horizontal coordinate directions, ie, in x and y directions. An x-y slide 8 of conventional design is known, for example, from DE 19807771 A1 (corresponding to US patent 6095066). The drive of the x-y slide 8 takes place via drives only roughly outlined in FIG. 8 , namely an x drive 9 and a y drive 10 , which are electric position-controlled motors, pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com