Plant for producing tyres of different types simultaneously

A technology of tires and types, applied in the direction of tires, applications, wheels, etc., can solve problems such as increased capital costs, increased capital costs of inventory products, and affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

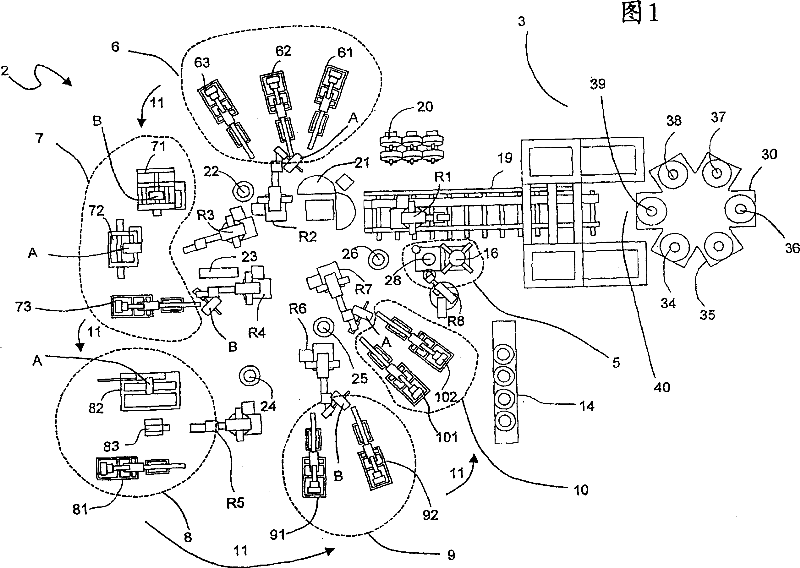

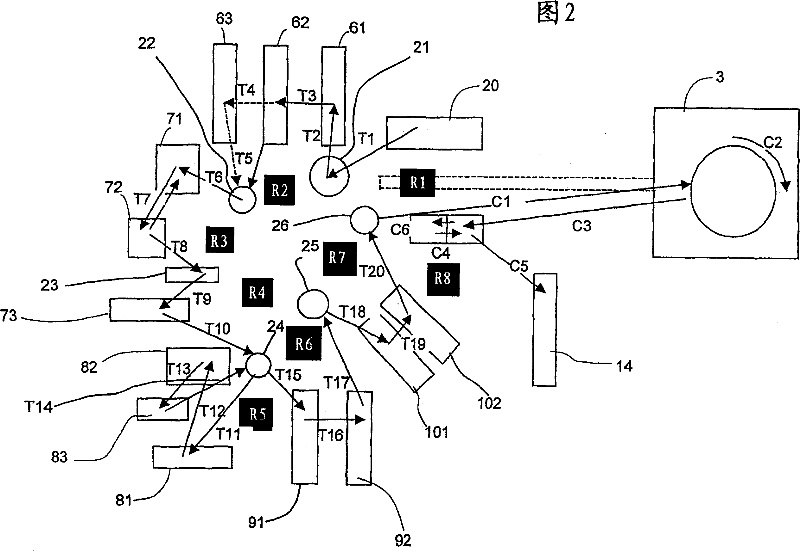

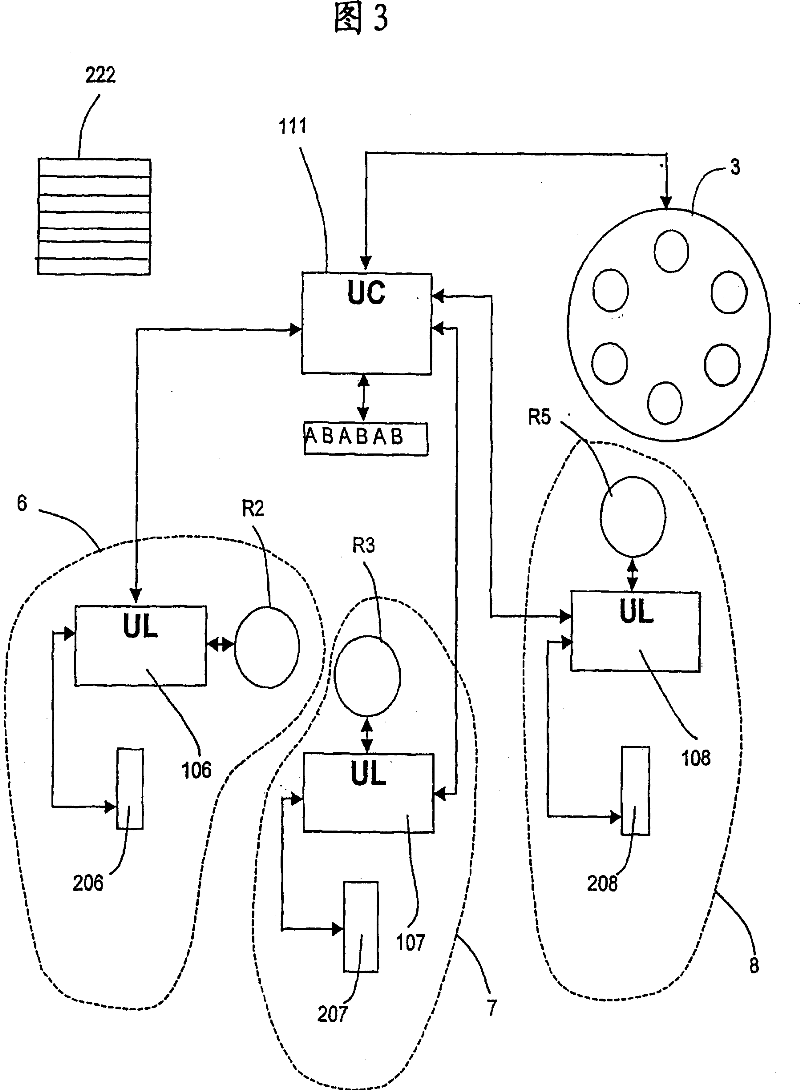

[0046] Figure 1 shows an embodiment of a plant for producing tires according to the invention. The plant comprises: an integrated processing unit 2 for the production of rough tires, wherein each produced tire is produced by assembling the structural components of the tire in a predetermined order; and an integrated vulcanization unit 3, wherein the Each tire from said combined processing unit 2 is vulcanized in a corresponding mold 34 , 35 , 36 , 37 , 38 , 39 .

[0047] The combined processing unit 2 includes a plurality of workstations 5, 6, 7, 8, 9, 10, which are arranged continuously along the processing path, preferably in a closed loop type, as shown by the arrow 11 in Fig. 1 . There is also a feeding station 20, a temperature stabilizing device 21, a first holding station 22, a multiple holding station 23, a second holding station 24, a third holding station 25 and a terminal holding station 26 on this line .

[0048] Workstations 5, 6, 7, 8, 9, 10 are capable of oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com