Clamping profile material

A profile and clamping technology, which is applied in the direction of building types, friction-clamped detachable fasteners, tents/canopies, etc., can solve problems such as loss and safety guarantees, eliminate sealing problems and increase possibilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

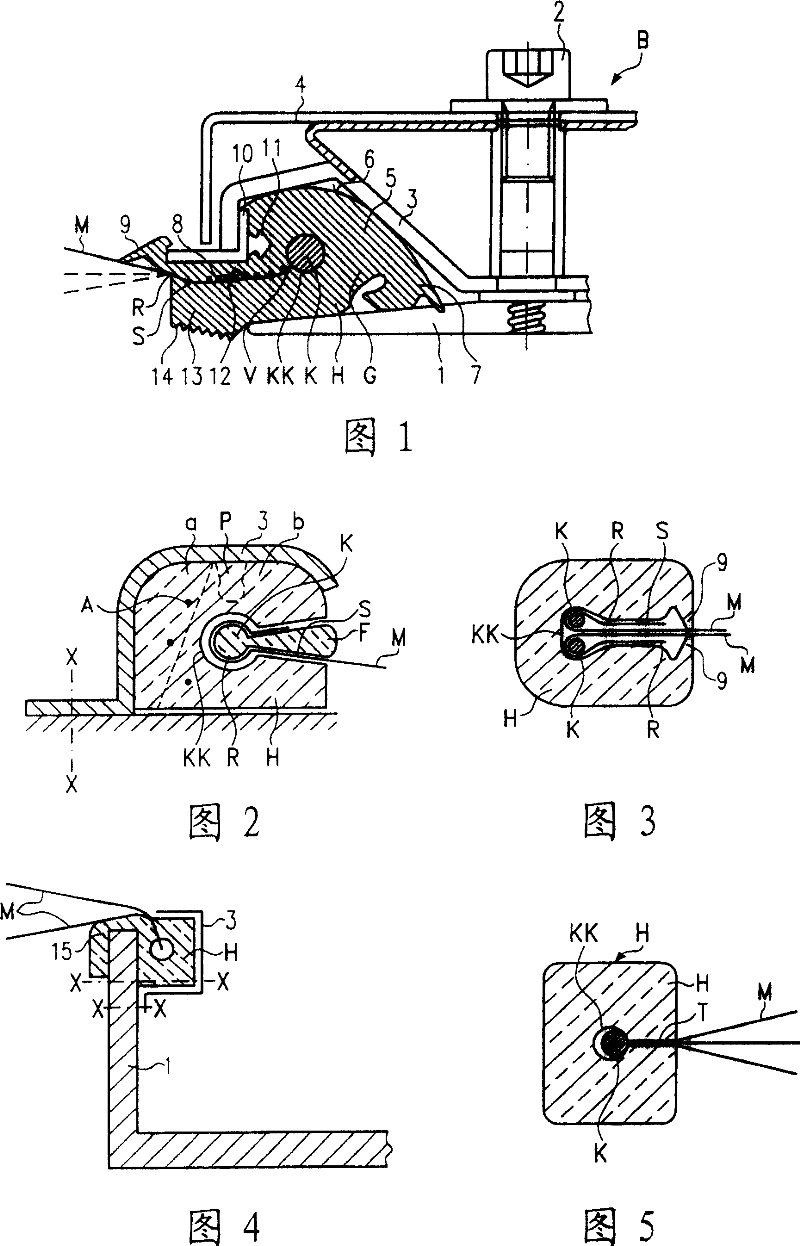

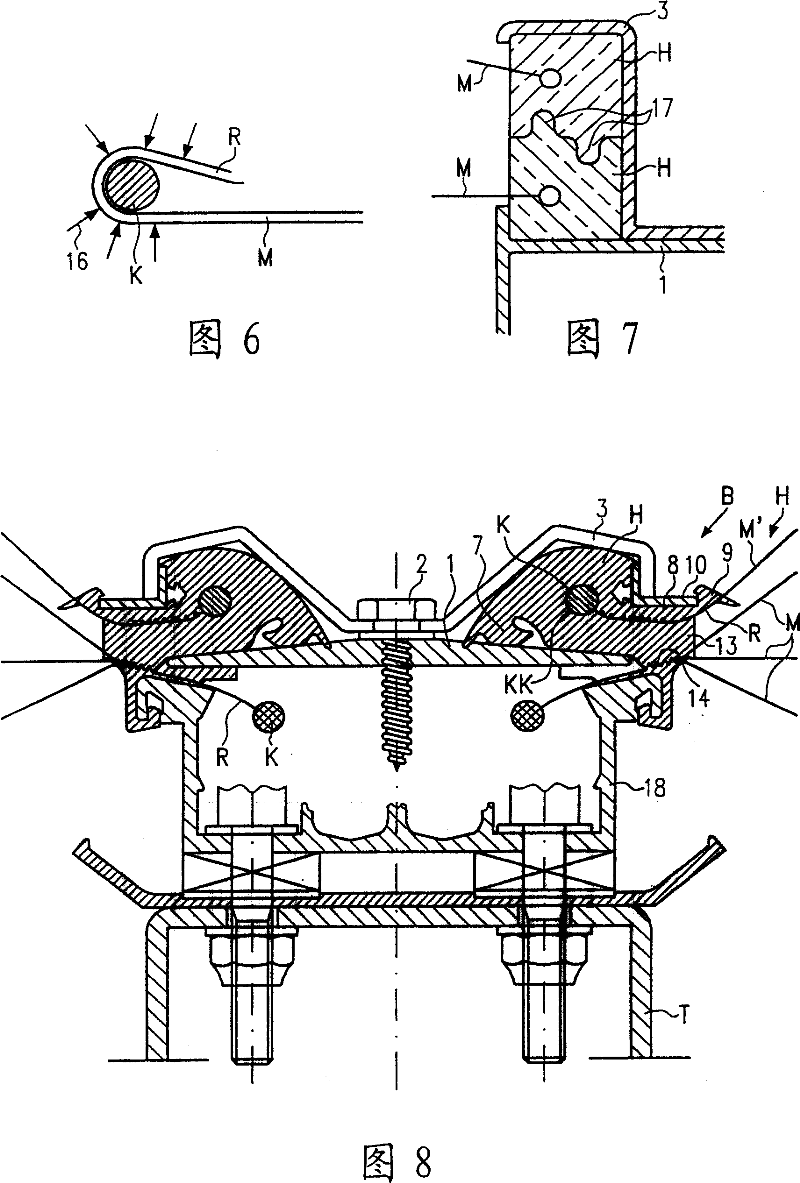

[0027] Figure 1 shows the support 1 of the load-bearing structure T (not shown in detail) of the membrane building B. The supporting structure T is used to fix at least one film M (in the form of a plastic film or fabric). The membrane M has at least a single layer, or has two layers (indicated by dashed lines), or even three layers. The edge R of the film M is fixed by the weather strip K in the weather strip guide groove KK of the clamping profile H, so that the edge R extends through the wing gap outlet S of the clamping profile H to the outside. For example, the wing gap outlet S starts at the throat portion V close to the weather strip guide groove KK. The part of the clamping profile H at least in the area of the weather strip guide groove KK or the wing gap outlet S is composed of rubber or elastomer G (for example, vulcanized EPDM or silicone rubber or the like). Preferably, the entire clamping profile H is composed of such a material. The consistency of the clamping pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com